OBDII (On-Board Diagnostics II) is a standardized system that allows external electronics to access vehicle diagnostic information. Central to this system are Parameter IDs (PIDs), codes that request specific data from the vehicle’s computer. This comprehensive Obdii Pid List provides a detailed table of common PIDs, explaining their function and how to interpret their data.

OBDII, governed by SAE J1979, enables communication with a vehicle’s internal systems through a standardized connector, typically located under the steering wheel. Devices like OBDII scanners and data loggers utilize this connector to send requests, formatted as CAN bus frames, to retrieve diagnostic data. These requests use PIDs to specify the desired information. For instance, requesting vehicle speed (PID 0D) involves sending a specific CAN frame. The vehicle responds with another frame containing the requested data, which is then decoded to a usable format.

J1939 data pack

J1939 data pack

Understanding OBDII Data Requests and Responses

A typical OBDII request consists of a CAN ID (e.g., 7DF) and a data payload containing the mode, PID, and other parameters. A sample request for vehicle speed could be:

| CAN ID | Byte 0 | Byte 1 | Byte 2 | Byte 3 | Byte 4 | Byte 5 | Byte 6 | Byte 7 |

|---|---|---|---|---|---|---|---|---|

| Request | 7DF | 02 | 01 | 0D | AA | AA | AA | AA |

The vehicle’s response includes a different CAN ID (e.g., 7E8) and data reflecting the requested value:

| CAN ID | Byte 0 | Byte 1 | Byte 2 | Byte 3 | Byte 4 | Byte 5 | Byte 6 | Byte 7 |

|---|---|---|---|---|---|---|---|---|

| Response (example) | 7E8 | 03 | 41 | 0D | AA | AA | AA | AA |

Decoding this response involves extracting relevant bytes and applying scaling and offset values specific to the PID. For example, to calculate vehicle speed:

| Physical value (DEC) | = | 0 | + | 1 | * | 18 | = | 18 | km/h |

|---|

OBDII PID Table: Service 01 (Current Data)

This table lists commonly used OBDII PIDs for Service 01, which provides real-time or current data. Each entry includes crucial information for data interpretation:

| PID dec | PID hex | Name | Bit start | Bit length | Scale | Offset | Min | Max | Unit |

|—|—|—|—|—|—|—|—|—|

| 4 | 04 | Calculated engine load | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 5 | 05 | Engine coolant temperature | 31 | 8 | 1 | -40 | -40 | 215 | degC |

| 12 | 0C | Engine speed | 31 | 16 | 0.25 | 0 | 0 | 16384 | rpm |

| 13 | 0D | Vehicle speed | 31 | 8 | 1 | 0 | 0 | 255 | km/h |

| 16 | 10 | Mass air flow sensor air flow rate | 31 | 16 | 0.01 | 0 | 0 | 655 | grams/sec |

…(Full table in the original document is included here)…

This detailed table provides a crucial reference for understanding and utilizing OBDII data. Each PID’s specific parameters enable accurate interpretation of the vehicle’s diagnostic information. Note: some PIDs require specialized decoding beyond the scope of this table. Consult the SAE J1979 standard for complete details.

Utilizing OBDII PIDs in Practice

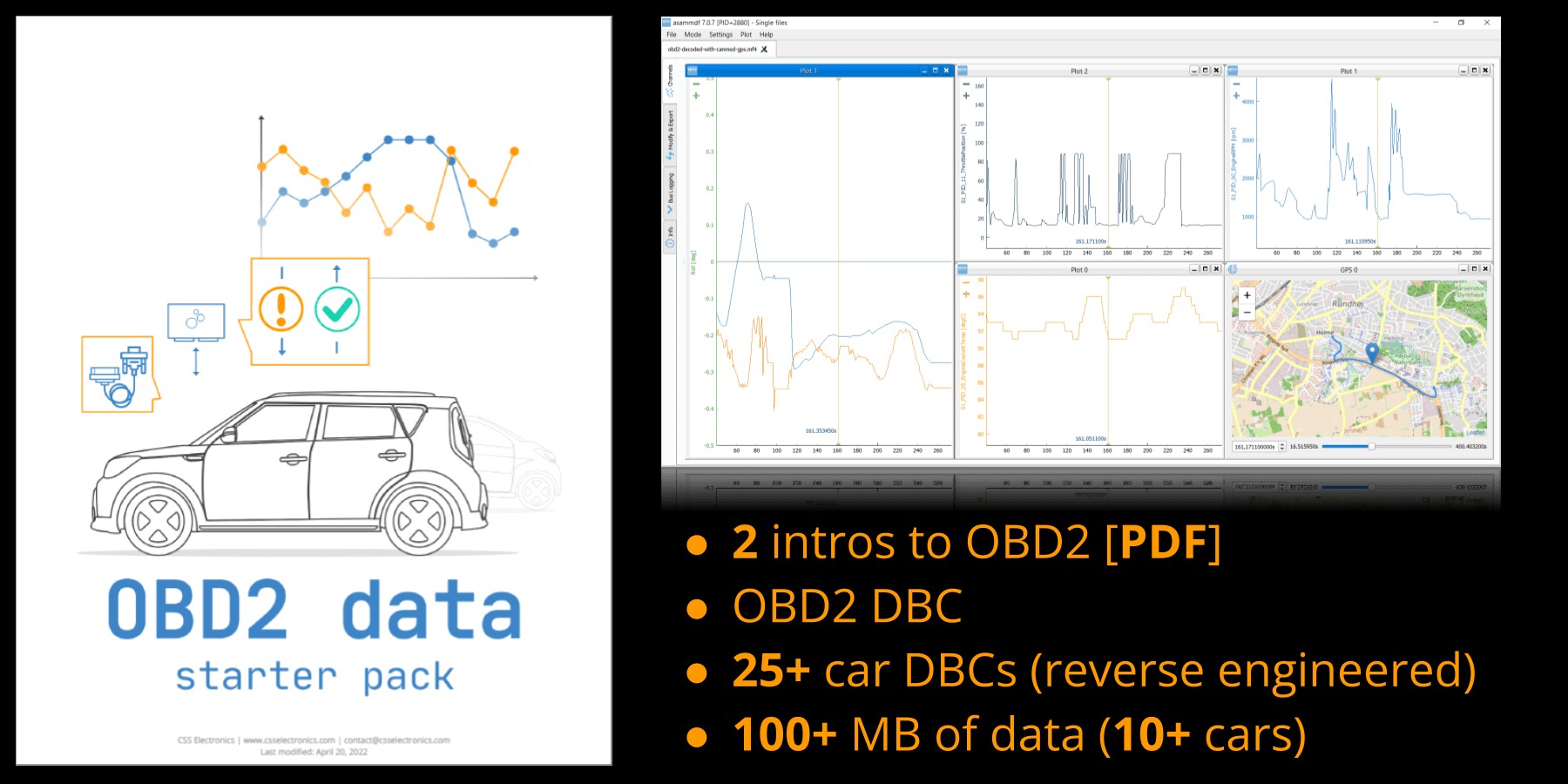

Accessing and decoding OBDII data requires specialized tools and software. OBDII DBC (database) files are essential for decoding raw CAN data using CAN bus software. These files contain the information needed to translate raw data into meaningful values. Additionally, OBDII CSV files provide a more simplified, spreadsheet-like format for storing PID information.

For practical application, using an OBDII data logger can record raw data from a vehicle, which can then be decoded using appropriate software and DBC files. This allows for in-depth analysis of vehicle performance and diagnostics.

Conclusion

Understanding and utilizing OBDII PIDs is crucial for vehicle diagnostics and performance analysis. This comprehensive list provides a valuable resource for interpreting OBDII data. Remember to refer to the complete SAE J1979 standard for detailed information on all available PIDs and their specific decoding requirements. For hands-on experience, consider using an OBDII scanner or data logger combined with compatible software to explore the wealth of information available through your vehicle’s OBDII system.