Understanding your vehicle’s health and performance is crucial for maintenance, repair, and even enhancing driving efficiency. Modern vehicles are equipped with sophisticated On-Board Diagnostic systems, and at the heart of this system are Obdii Pids (Parameter IDs). This guide will delve into the world of OBDII PIDs, explaining what they are, how they function, and why they are indispensable for anyone involved in automotive diagnostics, data logging, or vehicle performance analysis.

What are OBDII PIDs?

OBDII, or On-Board Diagnostics II, is a standardized system in vehicles that provides access to a wealth of information about the vehicle’s operation. OBDII Parameter IDs (PIDs) are codes used to request data from a vehicle’s Electronic Control Unit (ECU) through the OBDII port. Think of them as specific addresses that allow you to query the car’s computer for real-time data on various parameters.

These parameters range from engine speed and coolant temperature to more complex readings like fuel trim and oxygen sensor voltage. The standardization of OBDII PIDs is largely governed by the SAE J1979 standard, ensuring a degree of uniformity across different vehicle makes and models, especially within the same region (like North America for OBDII). This standardization is what allows universal OBDII scan tools and interfaces to communicate with a wide range of vehicles.

OBDII PIDs serve several key purposes:

- Diagnostic Trouble Code (DTC) Support: While PIDs are for real-time data, they are closely related to DTCs. Understanding PIDs can help in interpreting the conditions under which DTCs are set.

- Real-time Data Monitoring: PIDs allow mechanics and enthusiasts to monitor live data streams from the engine and other vehicle systems, essential for diagnosing intermittent issues or performance problems.

- Performance Analysis and Tuning: By logging and analyzing PID data, you can gain insights into vehicle performance, fuel efficiency, and identify areas for potential improvement or tuning.

- Custom Applications and Telematics: Developers use OBDII PIDs to create custom dashboards, data loggers, and telematics applications for vehicle tracking, fleet management, and more.

How OBDII PIDs Work: Request and Response Mechanism

Communication with a vehicle’s ECU via OBDII PIDs happens through a request-response mechanism, typically over the Controller Area Network (CAN bus). Here’s a breakdown of how it works:

-

OBDII Request: An external device, such as an OBDII scanner or data logger, sends a request to the vehicle. This request is formatted as a CAN bus frame and includes:

- CAN ID (typically 7DF): This is the functional request ID for OBDII queries.

- Data Payload: This payload contains the service code (e.g., 01 for “Show Current Data”), the PID code itself (e.g., 0D for Vehicle Speed), and padding bytes (e.g., AA or 55).

For example, to request the Vehicle Speed PID (0D), the request CAN frame might look like this:

CAN ID: 7DF Data Payload: 02 01 0D AA AA AA AA AAHere,

02indicates the number of data bytes following,01is the service code for current data, and0Dis the PID for vehicle speed. -

OBDII Response: If the vehicle supports the requested PID, the ECU will respond with a CAN bus frame containing the requested data. The response frame typically has:

- CAN ID (typically 7E8): This is the functional response ID, generally offset from the request ID (7DF + 7). There might be multiple response IDs (7E8, 7E9, 7EA, etc.) if multiple ECUs respond.

- Data Payload: This payload includes:

- The number of data bytes.

- The service code + 40 (e.g.,

41for service01responses). - The PID code (echoed back for confirmation).

- The data bytes representing the PID value.

- Padding bytes.

An example response for the Vehicle Speed request could be:

CAN ID: 7E8 Data Payload: 03 41 0D XX AA AA AA AAHere,

03indicates the number of data bytes,41confirms the service and response,0Dechoes the PID, andXXis the hexadecimal value representing the vehicle speed. -

Data Decoding: The raw data bytes in the response frame are typically in hexadecimal format and need to be decoded to get the physical value. This often involves:

- Identifying relevant bytes: OBDII PIDs often use one or more bytes for data.

- Converting from hexadecimal to decimal: The data bytes are usually big-endian, meaning they can be directly converted.

- Applying scale and offset: Many PIDs require a formula to convert the raw decimal value into a meaningful physical unit (e.g., km/h, rpm, degrees Celsius). This formula often takes the form:

Physical Value = Offset + (Scale * Raw Decimal Value)For instance, for Vehicle Speed (PID 0D), the scale is 1, and the offset is 0. If

XXin the response payload is18(hexadecimal), converting to decimal gives 18. Applying the formula:Vehicle Speed = 0 + (1 * 18) = 18 km/h

OBDII PID Lookup Table: Understanding the Parameters

A crucial resource for working with OBDII PIDs is a comprehensive lookup table. This table provides details for each PID, including its name, the bytes it uses in the response, and the formulas for converting the raw data to physical values.

Here’s a glimpse into a typical OBDII PID table (Service 01), focusing on commonly used parameters:

| PID (Dec) | PID (Hex) | Name | Bit Start | Bit Length | Scale | Offset | Min | Max | Unit |

| :——– | :——– | :————————– | :——– | :——— | :——- | :—– | :——- | :—– |

| 0 | 00 | PIDs supported [01-20] | 31 | 32 | 1 | 0 | Encoded | |

| 4 | 04 | Calculated engine load | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 5 | 05 | Engine coolant temperature | 31 | 8 | 1 | -40 | -40 | 215| degC |

| 12 | 0C | Engine speed | 31 | 16 | 0.25 | 0 | 0 | 16384| rpm |

| 13 | 0D | Vehicle speed | 31 | 8 | 1 | 0 | 0 | 255 | km/h |

| 15 | 0F | Intake air temperature | 31 | 8 | 1 | -40 | -40 | 215| degC |

| 16 | 10 | Mass air flow sensor air flow rate | 31 | 16 | 0.01 | 0 | 0 | 655 | g/sec |

| 17 | 11 | Throttle position | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

Understanding the Table Columns:

- PID (Dec/Hex): The Parameter ID in decimal and hexadecimal format. You’ll use the hex value in your OBDII requests.

- Name: A descriptive name of the parameter.

- Bit Start & Bit Length: Indicates where in the data payload the relevant data bytes begin and how many bits they occupy. In OBDII (Service 01), data typically starts at bit 31 and uses 8 or 16 bits.

- Scale & Offset: These are the values used in the formula

Physical Value = Offset + (Scale * Raw Decimal Value)to convert the raw data into physical units. - Min | Max: The expected minimum and maximum range for the physical value.

- Unit: The physical unit of measurement for the parameter.

Example: Decoding Engine Speed (PID 0C)

Let’s revisit the Engine Speed example from the original article. If the OBDII response payload for PID 0C is 04 41 0C 0A 0C AA AA AA, the data bytes for engine speed are 0A 0C.

-

Raw Decimal Value: Convert the hexadecimal

0A0Cto decimal: 2572. -

Apply Formula: Using the table, the scale for Engine Speed (PID 0C) is 0.25, and the offset is 0.

Engine Speed = 0 + (0.25 * 2572) = 643 rpm

This table approach, similar to CAN database (DBC) file syntax, provides a structured and efficient way to decode OBDII PID data.

Programmatic Formats: DBC and CSV for OBDII PIDs

For developers and advanced users, OBDII PID information is also available in programmatic formats like DBC and CSV.

-

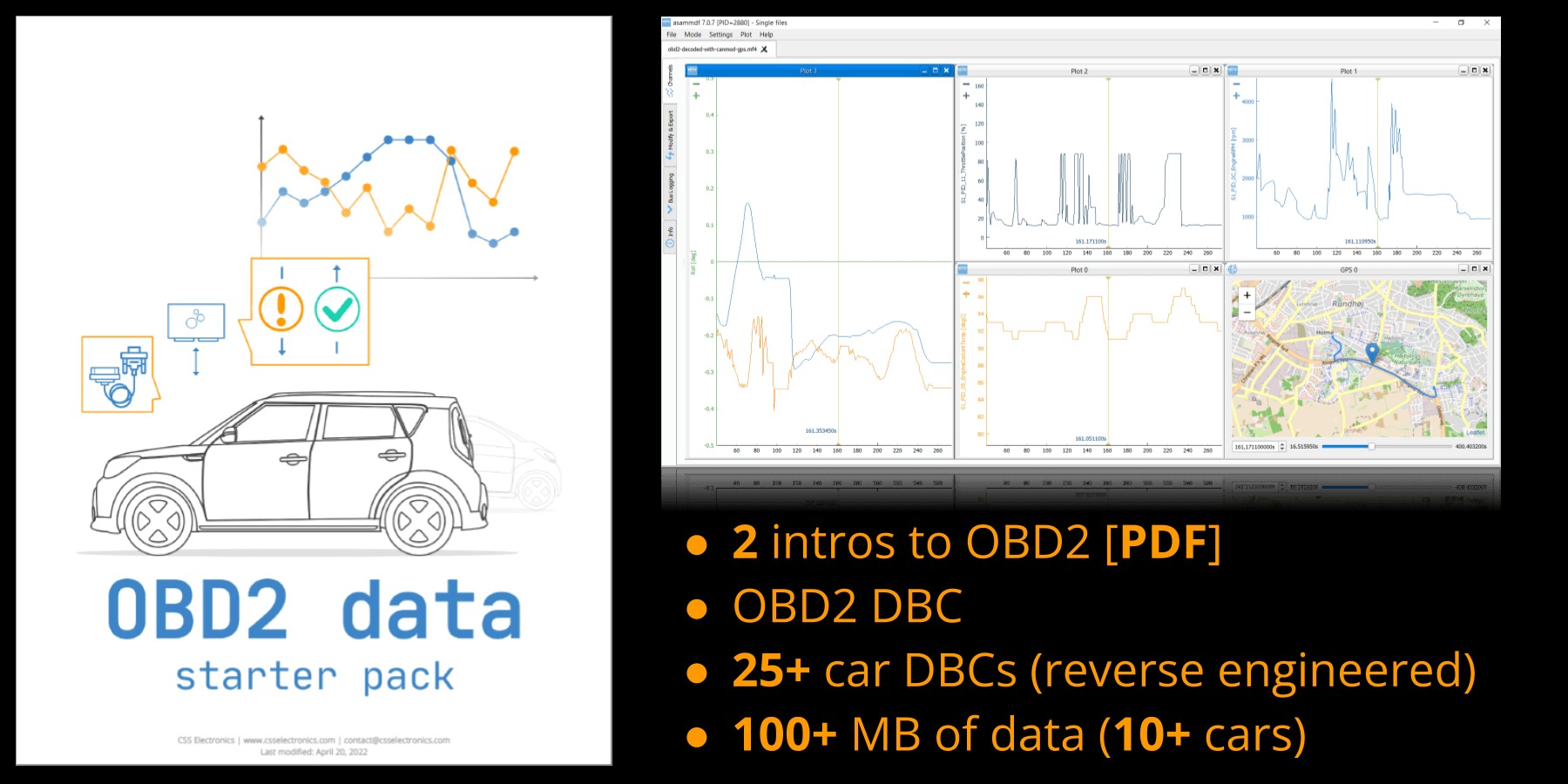

DBC (CAN Database) File: A DBC file for OBDII PIDs allows you to use CAN bus software tools to automatically decode raw CAN frames containing OBDII responses. This is invaluable when working with OBDII data loggers or interfaces, streamlining the process of converting raw data into human-readable values. Tools like asammdf GUI and many commercial CAN analysis tools support DBC files.

-

CSV (Comma Separated Values) File: A CSV file provides the same information as the lookup table but in a plain text, comma-separated format. This is useful for scripting languages like Python or for importing into spreadsheet software. If you are building custom OBDII decoding logic from scratch, a CSV file can be a convenient data source.

Tools and Resources:

- Free Sample OBDII Data: For testing and development, you can find sample OBDII data logs online, often in MF4 format, which can be opened with tools like asammdf GUI.

- Open Source Python API: Libraries like the

python-canand custom APIs provide ways to interact with CAN bus data and decode OBDII PIDs programmatically. These can be used to build custom telematics dashboards or data analysis pipelines.

Learn more about our OBD2 Data Pack

J1939 data pack

J1939 data pack

Why is Understanding OBDII PIDs Important?

OBDII PIDs are more than just technical codes; they are the key to unlocking a wealth of vehicle data. Understanding and utilizing OBDII PIDs is essential for:

- Enhanced Vehicle Diagnostics: Go beyond basic fault codes. PIDs allow for in-depth analysis of sensor data, helping to pinpoint the root cause of issues, especially intermittent problems that don’t always trigger DTCs.

- Proactive Vehicle Maintenance: By monitoring PIDs like engine temperature, coolant temperature, and battery voltage, you can identify potential problems before they escalate into major failures, enabling preventative maintenance.

- Optimizing Fuel Efficiency and Performance: Data from PIDs like engine load, throttle position, and air-fuel ratio can be used to analyze driving habits and identify areas for improvement in fuel economy. Performance enthusiasts can use PID data for fine-tuning engine parameters.

- Developing Innovative Automotive Applications: From telematics and fleet management solutions to custom car dashboards and DIY diagnostic tools, OBDII PIDs are the foundation for a wide range of automotive innovations.

Conclusion

OBDII PIDs are fundamental to modern vehicle diagnostics and data access. Whether you are a professional mechanic, an automotive engineer, a car enthusiast, or a software developer working on automotive applications, understanding OBDII PIDs is a valuable skill. By utilizing OBDII PID lookup tables, programmatic formats, and the right tools, you can tap into the rich data stream your vehicle provides, leading to better diagnostics, improved maintenance, and exciting new possibilities in automotive technology. Explore the resources available, dive into the data, and unlock the potential of OBDII PIDs in your automotive endeavors.