The On-Board Diagnostics II (OBD2) system is a cornerstone of modern vehicle maintenance and diagnostics. It’s a standardized system that provides access to a wealth of data about a vehicle’s operation, enabling mechanics and enthusiasts alike to monitor performance, diagnose issues, and ensure optimal functioning. At the heart of OBD2 are Parameter IDs, or PIDs, which are codes used to request specific data points from a vehicle’s computer. To effectively use this data, especially in diverse applications, understanding and utilizing an Obdii Data Converter is crucial.

This article provides a comprehensive overview of OBD2 PIDs, how to interpret them, and how an OBDII data converter plays a vital role in making this data accessible and usable. We’ll delve into the structure of OBD2 requests and responses, explore common PIDs, and highlight the tools and resources available to work with OBD2 data effectively.

Decoding OBD2 PIDs: How Data is Transmitted

OBD2 communication relies on standardized protocols, primarily through the Controller Area Network (CAN bus) in modern vehicles. When a diagnostic tool or an OBDII data converter requests information, it sends a specific CAN frame to the vehicle’s Electronic Control Unit (ECU). This request typically includes:

- CAN ID (e.g., 7DF): Identifies the message sender and recipient. For OBD2 requests, 7DF is a common ID.

- Data Payload: Contains the request parameters, including the service mode and the PID being requested.

For instance, to request the vehicle speed (PID 0D), a request frame might look like this:

CAN ID: 7DF

Data Payload: 02 01 0D AA AA AA AA AA- 02: Number of data bytes following.

- 01: Service 01, indicating “Show current data”.

- 0D: The PID for Vehicle Speed.

- AA AA AA AA AA: Padding bytes.

Upon receiving a valid request, the vehicle’s ECU responds with a CAN frame containing the requested data. A response to the vehicle speed request might be:

CAN ID: 7E8

Data Payload: 03 41 0D XX AA AA AA AA- 03: Number of data bytes following.

- 41: Response code, indicating a positive response to service 01 (0x40 + 0x01).

- 0D: The requested PID.

- XX: The hexadecimal value representing the vehicle speed.

- AA AA AA AA: Padding bytes.

The crucial step then becomes converting this hexadecimal data (‘XX’ in the example) into a human-readable physical value, such as kilometers per hour (km/h). This is where an OBDII data converter, whether it’s software, a dedicated hardware tool, or a lookup table, becomes essential.

The OBD2 PID Table: Your Key to Data Interpretation

To facilitate the conversion process, resources like OBD2 PID tables are invaluable. These tables provide the necessary information to decode the raw data received from the vehicle. Instead of simply providing raw hexadecimal values, an OBDII data converter utilizes these tables (or similar algorithms) to present the data in meaningful units.

The OBD2 PID table typically includes the following key parameters for each PID:

- PID (Parameter ID): The hexadecimal or decimal code identifying the parameter.

- Name: A descriptive name of the parameter (e.g., Engine Speed, Vehicle Speed).

- Bit Start & Bit Length: Specifies the location and size of the data within the response payload.

- Scale & Offset: Mathematical factors used to convert the raw data value into a physical value.

- Min/Max Values: The valid range for the parameter.

- Unit: The physical unit of measurement (e.g., rpm, km/h, degC).

Let’s revisit the example of Engine Speed (PID 0C). According to the table, to decode the response payload 04 41 0C 0A 0C AA AA AA, we focus on the bytes 0A 0C.

- Raw Value (Hex):

0A0C - Raw Value (Decimal): Converting

0A0Cfrom hexadecimal to decimal yields 2572. - Scale Factor: From the table, the scale for Engine Speed is 0.25.

- Offset: The offset is 0.

Applying the formula:

Physical Value = Offset + (Scale * Raw Value)

Physical Value = 0 + (0.25 * 2572) = 643 rpmThus, the engine speed is 643 revolutions per minute. An OBDII data converter automates this calculation, presenting the 643 rpm value directly to the user.

Programmatic OBD2 Data Conversion and Tools

For developers and advanced users, programmatic approaches to OBD2 data conversion offer flexibility and integration possibilities. Several tools and file formats are designed for this purpose:

-

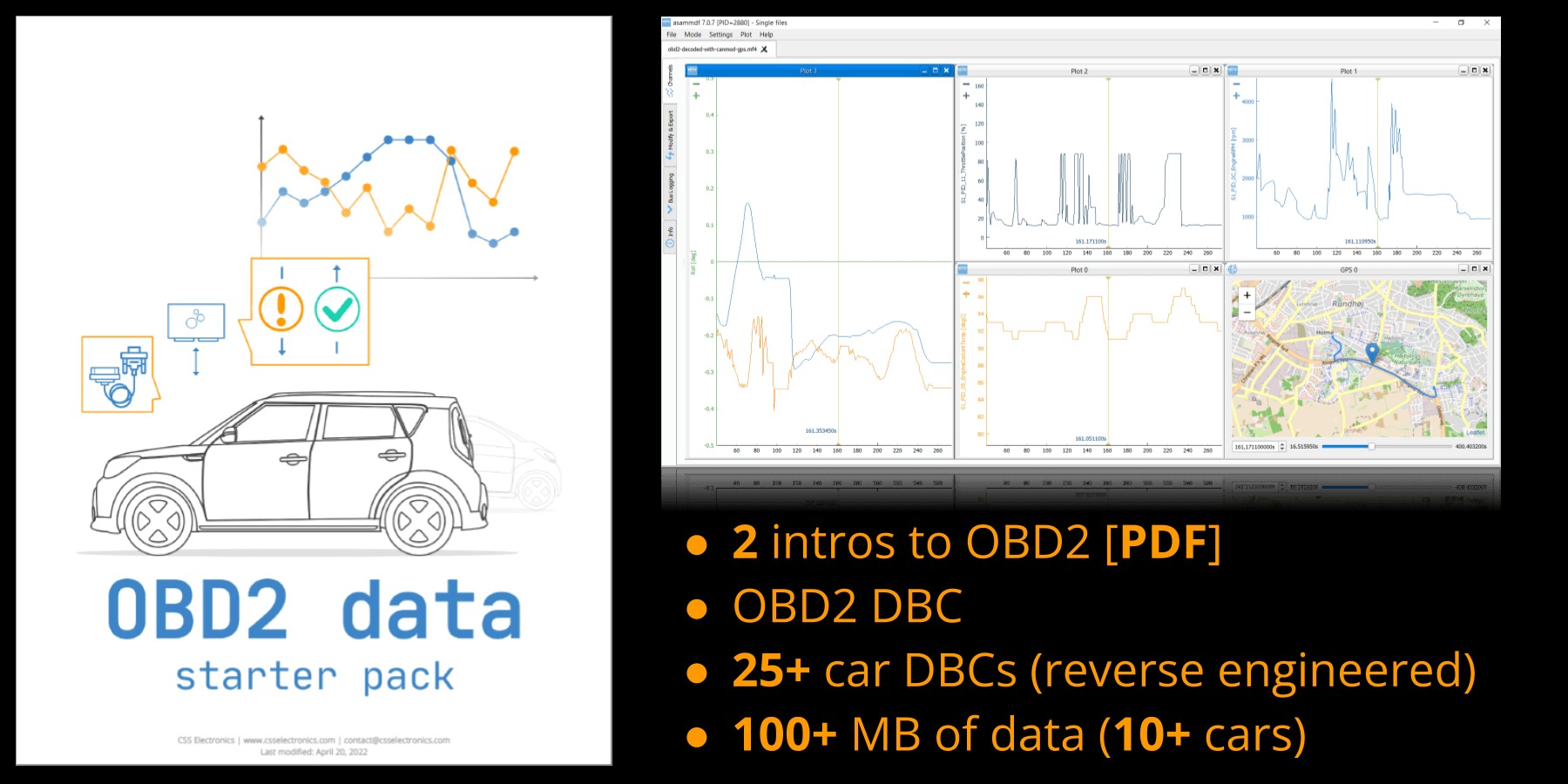

DBC Files (.dbc): CAN database files (.dbc) are widely used in the automotive industry to define CAN message structures and signal decoding rules. An OBD2 DBC file contains definitions for OBD2 PIDs, making it easy to decode raw CAN frames containing OBD2 responses using CAN bus software tools. This acts as a sophisticated OBDII data converter definition file for software applications.

-

CSV Files (.csv): Comma-Separated Value (CSV) files provide a simpler, tabular format for OBD2 PID information. A CSV file can be easily parsed by scripts or imported into spreadsheet software, offering a basic form of OBDII data converter logic that can be implemented in custom applications.

-

Software APIs: Open-source APIs, like Python libraries for CAN bus, enable developers to create custom OBDII data converters. These APIs allow for reading raw CAN data from log files or live interfaces and applying DBC or custom decoding logic to extract and convert OBD2 PID values.

J1939 data pack

J1939 data pack

For users who prefer ready-made solutions, various OBD2 tools incorporate OBDII data converter functionality directly:

- OBD2 Scanners: Handheld scanners are designed for quick diagnostics and often display PID values in physical units on their screens.

- OBD2 Interfaces with Software: Interfaces connecting a vehicle to a computer, paired with diagnostic software, provide real-time PID data monitoring and conversion.

- OBD2 Data Loggers: These devices record raw CAN data, which can then be processed offline using software tools with built-in OBDII data converter capabilities or custom scripts.

Maximizing the Value of OBD2 Data with Conversion

The ability to convert raw OBD2 data into meaningful physical values is what unlocks the true potential of vehicle diagnostics and performance monitoring. An effective OBDII data converter is not just a convenience; it is a necessity for:

- Accurate Diagnostics: Understanding engine temperature in degrees Celsius or vehicle speed in km/h is essential for accurate problem identification.

- Performance Analysis: Monitoring parameters like engine load, throttle position, and fuel trim, converted into percentages or ratios, allows for in-depth performance evaluation.

- Custom Applications: For telematics, data logging, or custom dashboards, converting OBD2 data is crucial for presenting information in a user-friendly and actionable format.

In conclusion, whether you are a professional mechanic, an automotive engineer, or a car enthusiast, understanding OBD2 PIDs and utilizing an OBDII data converter are fundamental skills. By leveraging the tools and resources available, you can effectively tap into the rich data stream provided by the OBD2 system, gaining valuable insights into vehicle operation and performance. Explore our resources on OBD2 interfaces, data loggers, and software tools to further enhance your capabilities in working with OBD2 data.

Learn more about OBD2 via our videos below:

OBD2 introduction

OBD2 logging intro

OBD2 data loggers