Understanding the inner workings of your vehicle’s transmission is crucial for effective diagnostics and repair. While OBDII codes like P1665 in hexadecimal format (0xP1665) might point towards issues in various vehicle systems, a solid grasp of mechanical components, such as the 4L60E transmission, remains indispensable for any automotive professional or dedicated car enthusiast. This guide delves into the internals of the 4L60E transmission, breaking down its components and common failure symptoms to enhance your diagnostic skills.

The 4L60E, a popular electronically controlled automatic transmission, relies on a complex interaction of clutches, bands, and sprags to deliver power and smooth gear changes. Let’s explore these key components:

1. Low Roller Clutch

This is a one-way clutch mechanism. It’s designed with rollers and an accordion spring that allows rotation in only one direction. Think of it like a ratchet.

Symptoms of Failure: The most prominent symptom is the absence of movement from a standstill in Drive or Overdrive. However, vehicles might still move in manual low gear (and potentially second gear in cars designed for second-gear starts). Once the vehicle is in motion, shifting through the gears might function normally until the next stop. In manual low gear, the low/reverse clutch engages, bypassing the faulty low roller clutch and enabling movement. Interestingly, starting in manual low can provide added strength at the track, leveraging this clutch engagement.

2. Input Sprag

Similar in function to the low roller clutch, the input sprag is another one-way clutch.

Symptoms of Failure: A failed input sprag typically results in no movement in Overdrive (OD). The vehicle will, however, still operate in manual 2-1 positions and may allow manual shifting through all four gears. This is because in manual low gears, the overrun clutch engages, providing an alternate power path that bypasses the input sprag. Conversely, if the sprag becomes locked or bound, it can create a sensation of the brakes being applied during the 3-4 shift, as it’s meant to freewheel in 4th gear.

3. Forward Clutch Set

This clutch set is engaged in all forward gears (1st, 2nd, and 3rd) and is responsible for transmitting power in these gears. It freewheels in 4th gear due to sprag reversal.

Symptoms of Failure: Failure of the forward clutch set often manifests as slipping in all forward gears or complete lack of movement. Similar to sprag failures, selecting manual 1st or 2nd gear might temporarily alleviate symptoms as the overrun clutch can compensate for a damaged forward clutch. However, in many cases, both clutches might be compromised simultaneously.

4. 3-4 Clutch Set (Direct Clutch)

Despite being labeled “3-4”, this clutch is more accurately termed the 3rd or direct clutch. It’s engaged in both 3rd and 4th gear.

Function: When engaged along with the forward clutch and a holding sprag, it creates a 1:1 ratio, meaning direct drive with no gear reduction or multiplication.

Symptoms of Failure: A common symptom is normal operation in 1st and 2nd gear, followed by a neutral sensation when 3rd gear should engage. However, this isn’t true neutral; it’s actually a return to first gear. Prior to complete failure, drivers may experience slipping in 3rd and 4th gears. While often associated with a no 2-3 shift at wide-open throttle (WOT), this isn’t always the case if shifts are solid at lower throttle positions.

5. 2-4 Band

This component is used for both 2nd and 4th gear engagement, although activated by different servos for each gear.

Function: In 2nd gear, the band, applied by the 2nd gear servo, halts the rotation of the reverse input drum and sunshell, creating the 2nd gear ratio through the planetary gearset. In 4th gear, it’s applied while the 3-4 clutch is engaged to achieve the 4th gear ratio.

Symptoms of Failure: Failure of the 2-4 band typically results in slipping or complete loss of 2nd and 4th gears.

6. Reverse Input Set and Low/Reverse Clutch Set

These two sets work in conjunction to enable reverse gear.

Symptoms of Failure: Failure in either set will lead to no reverse or slipping in reverse. As mentioned earlier, the low/reverse clutch, while not active in forward gears except manual low, provides engine braking and support for the low roller clutch when manual low is selected.

7. Input Drum

The input drum is a critical housing that contains the overrun, forward, and 3-4 clutch sets, as well as the input sprag. The input shaft connects directly into it.

Symptoms of Failure: A failure of the input drum, which is less common but severe, will result in no movement in any gear, forward or reverse, despite the presence of pump pressure. All engine power must transmit through this drum.

8. Sunshell

The sunshell is integral for reverse, 2nd, and 4th gears.

Common Failure: A frequent issue is the stripping of splines at its base. This leads to the loss of reverse, 2nd, and 4th gears. Upgraded “BEAST sunshells” are commonly used replacements to address this weakness.

9. Planets (Planetary Gear Sets)

The 4L60E utilizes both front and rear planetary gear sets, available in 4-pinion (older 700R4 and 4L60E) and 5-pinion (4L65E) configurations.

Common Failures:

A. Lube Starvation: Often due to a damaged input drum seal disrupting lubrication flow to the planets via the output shaft, or contamination from converter failures blocking oil passages. Symptoms: Whizzing, grinding noises, and eventual loss of movement. Upon inspection, planet gears will show signs of heat damage (blackened or blue).

B. Planet Housing Failure: Typically spline stripping at the base of the rear planet.

10. Reaction Carrier Shaft

The most common failure here is a break in the tube/shaft, often associated with rear planet failures.

11. Valve Body Assembly

While generally reliable, the valve body can experience failures, primarily electrical solenoid issues.

Common Mechanical Failure: Wear in the bore of the converter regulator (iso valve) can cause leaks, leading to slipping lockup or the P01870 OBDII code. Repair options range from blocking PWM function to valve body reaming and replacement with updated valves from companies like Sonnax or TransGo.

12. Pump Assembly

The pump is vital for transmission operation, providing essential hydraulic pressure.

Failures are often installation-related:

A. Converter Misalignment: If the torque converter isn’t fully seated during installation, it can cause immediate pump failure at startup or shortly after due to stress.

B. Converter Spacing Issues: Excessive converter spacing can cause the flexplate and converter to flex forward at higher RPMs, leading to pump damage when the converter loses alignment and then slams back as RPM decreases.

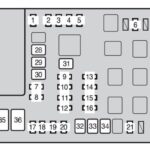

DIAGRAM 1: External Case Exploded View

Visual aids are invaluable in understanding complex systems. The exploded diagrams below illustrate the external case components of the 4L60E.

In Conclusion:

While OBDII codes like P1665 (0xP1665) can be a starting point in diagnosing vehicle issues, understanding the mechanical intricacies of components like the 4L60E transmission is paramount for accurate diagnosis and effective repair. This guide provides a foundational understanding of common 4L60E internal failures, empowering mechanics and enthusiasts to approach transmission diagnostics with greater confidence and knowledge. Remember to always consult professional diagnostic tools and repair manuals for specific troubleshooting and repair procedures.