Decoding Trouble Code P0750: Shift Solenoid A Malfunction

Navigating the complexities of modern vehicle diagnostics can be daunting, especially when faced with error codes. Among these, the OBDII error code P0750, also known as the EOBD error code P0750 in European markets, signals a “Shift Solenoid A Malfunction”. This generic powertrain code indicates an issue within the automatic transmission system, specifically pointing towards the Shift Solenoid A circuit. While this code is applicable across a broad spectrum of OBD-II compliant vehicles from manufacturers like Ford, Chrysler, Honda, Toyota, and VW, the precise diagnostic and repair procedures can vary depending on the vehicle’s year, make, model, and transmission configuration. Understanding the intricacies of the P0750 code is the first step towards effective vehicle maintenance and repair.

Automatic transmissions in modern vehicles rely on a complex hydraulic system managed by electronic controls to ensure smooth and efficient gear changes. At the heart of this system are shift solenoids, typically labeled A, B, and C, which are essentially electro-hydraulic valves. The Shift Solenoid A, the focus of the P0750 code, plays a crucial role in directing transmission fluid pressure to the appropriate clutches and bands within the transmission. This precise fluid management is what facilitates gear changes, optimizing engine performance and fuel efficiency by maintaining the lowest possible RPM for any given driving condition. When the Powertrain Control Module (PCM) – the vehicle’s central computer – detects a malfunction in the electrical circuit controlling Shift Solenoid A, it triggers the P0750 error code, illuminating the Check Engine Light and potentially other transmission warning lights. Codes such as P0751, P0752, P0753, and P0754 are closely related, each indicating a specific type of malfunction within the Shift Solenoid A circuit.

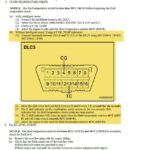

Alt text: Diagram illustrating the location and function of shift solenoids within an automatic transmission valve body, highlighting Solenoid A.

Severity of the P0750 Error

The P0750 error code should be considered a moderately severe issue initially, but it has the potential to escalate rapidly if left unaddressed. Ignoring this error can lead to significant transmission damage and more costly repairs down the line. The malfunction in the shift solenoid circuit disrupts the transmission’s ability to shift gears correctly, leading to a cascade of potential problems that can affect both the vehicle’s performance and its longevity. Prompt diagnosis and repair are crucial to prevent further complications and ensure the continued reliable operation of your vehicle.

Common Symptoms Associated with P0750

The symptoms of a P0750 trouble code can manifest in various ways, impacting the vehicle’s drivability and overall performance. Recognizing these symptoms early can aid in timely diagnosis and repair. Common indicators of a P0750 error include:

- Transmission Slipping: You might notice the engine RPM suddenly increasing without a corresponding increase in vehicle speed. This indicates the transmission is struggling to maintain the correct gear.

- Transmission Overheating: Inefficient gear changes due to a malfunctioning shift solenoid can cause the transmission to work harder and overheat. This can be signaled by a transmission temperature warning light or noticeable heat emanating from the transmission area.

- Transmission Stuck in Gear: The vehicle might become locked in a single gear, unable to shift up or down. This severely limits speed and power, making driving unsafe.

- Reduced Fuel Economy: When the transmission is not shifting optimally, the engine has to work harder, leading to increased fuel consumption and decreased efficiency.

- Misfire-like Symptoms: Jerky acceleration or a feeling of engine misfire can occur as the transmission struggles to engage the correct gear smoothly.

- Vehicle Entering Limp Mode: In some cases, the PCM may activate “limp mode” to protect the transmission from further damage. This mode restricts engine power and speed, significantly limiting vehicle performance.

- Check Engine Light Illumination: This is the most obvious sign, indicating that the PCM has detected a fault and stored the P0750 code.

Potential Causes of the P0750 Code

Several factors can contribute to a P0750 error code. Pinpointing the exact cause is crucial for effective repair. Common culprits include:

- Low Transmission Fluid Level: Insufficient fluid can lead to inadequate hydraulic pressure, affecting solenoid operation and triggering the P0750 code.

- Contaminated or Degraded Transmission Fluid: Dirty or old fluid can clog valve bodies and solenoids, hindering their function. Contaminants can also reduce the fluid’s lubricating properties, leading to mechanical issues.

- Clogged Transmission Filter: A blocked filter restricts fluid flow, starving the solenoids and other transmission components of necessary hydraulic pressure.

- Defective Transmission Valve Body: The valve body houses the solenoids and intricate hydraulic passages. Internal faults or blockages within the valve body can directly impact solenoid performance.

- Restricted Hydraulic Passages: Blockages or restrictions in the transmission fluid lines can impede fluid flow and solenoid operation.

- Internal Transmission Failure: While less common as a direct cause of P0750 initially, pre-existing internal mechanical issues within the transmission can sometimes manifest as solenoid circuit errors.

- Faulty Shift Solenoid A: The solenoid itself might be electrically or mechanically defective, failing to operate correctly when commanded by the PCM.

- Corroded or Damaged Connectors: Electrical connectors to the shift solenoid and transmission control system are exposed to harsh under-vehicle conditions. Corrosion or physical damage can disrupt electrical signals.

- Faulty or Damaged Wiring: Wiring harnesses leading to the shift solenoid can be damaged due to heat, vibration, or physical abrasion, causing open circuits or shorts.

- Faulty PCM: In rare cases, the PCM itself might be malfunctioning, sending incorrect signals or misinterpreting sensor data, leading to a false P0750 code.

Diagnosing and Troubleshooting the P0750 Error

A systematic approach to troubleshooting is essential for accurately diagnosing the root cause of a P0750 error. Start with basic checks and progressively move towards more advanced diagnostic procedures.

Initial Inspection: Fluid and Wiring

- Check Transmission Fluid Level and Condition: Use the vehicle’s dipstick to verify the fluid level is within the recommended range. Examine the fluid’s color and smell. Healthy transmission fluid is typically reddish and has a slightly sweet smell. Dark, burnt-smelling fluid indicates contamination or overheating, suggesting a fluid and filter change is necessary.

- Visual Wiring Inspection: Thoroughly inspect the wiring harnesses and connectors associated with the transmission and shift solenoids. Look for:

- Scraping or Rubbing: Wires rubbing against chassis components can wear through insulation.

- Bare Wires: Exposed wires can short circuit or corrode.

- Burn Spots: Indicate overheating or electrical shorts.

- Corrosion: Greenish or white deposits on connectors indicate corrosion, which can impede electrical conductivity.

- Damaged Pins: Bent or broken pins in connectors can prevent proper electrical contact.

- Connector Security and Integrity: Ensure all connectors are securely fastened and properly seated. Check for any signs of damage or looseness.

- Transmission Linkage Inspection: If applicable, inspect the transmission linkage for proper adjustment and freedom of movement. Binding or misadjusted linkage can sometimes indirectly affect solenoid operation.

Advanced Diagnostic Steps

For more in-depth diagnosis, specialized tools and vehicle-specific technical information are required.

- Diagnostic Scan Tool: Use an OBD-II scan tool to confirm the P0750 code is present and check for any other related transmission codes. A professional-grade scan tool can provide live data readings from the transmission sensors and solenoids, offering valuable insights into the system’s operation.

- Technical Service Bulletins (TSBs): Consult TSBs for your specific vehicle year, make, and model. Manufacturers often issue TSBs to address known issues and provide specific diagnostic procedures.

- Digital Multimeter: A digital multimeter is essential for electrical circuit testing. Refer to the vehicle’s service manual for specific voltage and resistance values for the Shift Solenoid A circuit.

- Continuity Testing: With the ignition off and the solenoid connector disconnected, perform continuity tests on the solenoid circuit wiring. Normal wiring should exhibit very low resistance (close to 0 ohms). High resistance or no continuity indicates open circuits or shorts.

- Solenoid Resistance Test: Measure the resistance of the Shift Solenoid A itself. Compare the reading to the manufacturer’s specifications. An out-of-range reading suggests a faulty solenoid.

- Solenoid Activation Test (if supported by scan tool): Some advanced scan tools can activate individual solenoids. This allows you to listen for the solenoid clicking and verify its mechanical operation.

Safety Note: Always disconnect the vehicle’s battery and follow proper safety procedures when working on electrical and hydraulic systems. Refer to the vehicle’s service manual for specific safety precautions and procedures.

Common Repairs for P0750 Code

Based on the diagnosis, common repairs for a P0750 error code include:

- Transmission Fluid and Filter Change: If the fluid is contaminated or low, a fluid and filter change is often the first step. This can resolve issues caused by fluid degradation or a clogged filter.

- Shift Solenoid A Replacement: If the solenoid is found to be faulty through resistance or activation tests, replacement is necessary.

- Transmission Valve Body Repair or Replacement: If the valve body is identified as the source of the problem due to internal blockages or damage, repair or replacement may be required. In some cases, replacing the entire valve body assembly is more practical.

- Transmission Flush: A transmission flush can help remove debris and contaminants from hydraulic passages, potentially resolving blockages.

- Connector Cleaning and Repair: Clean corroded connectors with electrical contact cleaner. Repair or replace damaged connectors as needed.

- Wiring Repair or Replacement: Repair damaged wiring by splicing and insulating wires properly. Replace entire wiring harnesses if damage is extensive.

- PCM Flashing or Replacement: If the PCM is diagnosed as faulty (which is rare), reprogramming (flashing) or replacement might be necessary. This should be considered as a last resort after all other possibilities have been ruled out.

Important Note: After performing any repairs, clear the P0750 code using a scan tool and test drive the vehicle to ensure the issue is resolved and the code does not return. Regular transmission maintenance, including fluid and filter changes at recommended intervals, can help prevent future solenoid and transmission problems.

While this guide provides a comprehensive overview of the Eobd/obdii Error P0750, always consult your vehicle’s specific service manual and technical resources for detailed diagnostic and repair procedures. For complex transmission issues, seeking assistance from a qualified automotive technician is highly recommended.