The OBDII error code P0300 is a common trouble code that signals your vehicle’s engine is experiencing random or multiple cylinder misfires. As an expert at autelfrance.com, understanding this Eobd/obdii Error-p0300 is crucial for both diagnosing and rectifying engine performance issues efficiently. This article delves into the causes, symptoms, diagnosis, and fixes associated with the P0300 code to help you get your vehicle running smoothly again.

What Does the Error Code P0300 Mean?

The P0300 code, when detected by your vehicle’s Engine Control Unit (ECU), indicates that a random or multiple misfire event has occurred across different cylinders. A misfire happens when there is incomplete combustion or a complete lack of combustion in one or more of the engine’s cylinders. This malfunction can stem from a variety of underlying issues affecting the engine’s ignition, fuel delivery, or mechanical components. Unlike other misfire codes that pinpoint a specific cylinder (like P0301 for cylinder 1, P0302 for cylinder 2, etc.), P0300 signifies that the misfire is not isolated to a single cylinder, making the diagnostic process potentially broader.

Common Causes of a P0300 Code

Several factors can trigger a P0300 code. Identifying the root cause is the first step to effective repair. Here are some of the most common culprits:

Worn or Fouled Spark Plugs

Spark plugs are critical for igniting the air-fuel mixture in the cylinders. Over time, spark plugs wear out, their electrodes erode, and they can become fouled with carbon deposits or oil. Worn spark plugs deliver a weaker spark, which can lead to incomplete combustion and engine misfires, triggering the eobd/obdii error-p0300.

Faulty Ignition Coils

Ignition coils are responsible for providing the high-voltage spark needed for the spark plugs. A weak or failing ignition coil may not generate sufficient voltage, resulting in a weak or non-existent spark. This can cause misfires, and because modern vehicles often use individual coils per cylinder or coil packs serving multiple cylinders, a failing coil can contribute to random misfires if multiple coils are affected or if it impacts cylinders randomly.

Clogged or Malfunctioning Fuel Injectors

Fuel injectors spray a precise amount of fuel into the cylinders. If fuel injectors become clogged or malfunction, they may not deliver enough fuel, or the fuel spray pattern may be compromised. This fuel starvation can cause a lean air-fuel mixture, leading to misfires and the P0300 code.

Vacuum Leaks

Vacuum leaks can disrupt the delicate air-fuel mixture balance required for efficient combustion. Leaks in vacuum lines, intake manifold gaskets, or other vacuum-operated components can allow unmetered air to enter the engine. This lean condition can cause random misfires across multiple cylinders, setting the P0300 code.

Exhaust Leaks

While less common, exhaust leaks, particularly near the oxygen sensors, can sometimes contribute to misfire codes. Exhaust leaks can affect the readings of oxygen sensors, which in turn can lead to incorrect fuel adjustments by the ECU, potentially causing misfires.

Low Fuel Pressure

Insufficient fuel pressure, often due to a failing fuel pump or a clogged fuel filter, can starve the engine of fuel. Low fuel pressure can result in a lean mixture and misfires across multiple cylinders, leading to the P0300 error.

Timing Issues

Incorrect engine timing, whether due to a stretched timing chain, worn timing belt, or issues with the crankshaft or camshaft position sensors, can cause misfires. Improper timing can lead to valves opening and closing at the wrong times, disrupting the combustion process.

Cylinder Head Gasket Failure

In more serious cases, a cylinder head gasket failure can cause coolant or oil to leak into the cylinders. This contamination can interfere with combustion, leading to misfires and potentially triggering the P0300 code.

Excessive Carbon Build-up on Intake Valves

Carbon deposits accumulating on the intake valves can restrict airflow into the cylinders. This restriction can lead to an improper air-fuel mixture and contribute to misfires, especially in direct-injection engines.

Driving with a P0300 Code: Is it Safe?

While a P0300 code might not immediately leave you stranded, it’s crucial to understand that driving with persistent engine misfires is not advisable. Initially, you might notice symptoms like rough idling, reduced engine power, and decreased fuel efficiency. However, ignoring a P0300 code can lead to more severe engine damage over time. Unattended misfires can cause damage to the catalytic converter due to unburnt fuel entering the exhaust system. Furthermore, prolonged misfires can increase stress on engine components and potentially lead to more costly repairs down the line. Therefore, it’s essential to diagnose and address the P0300 code as soon as possible.

Diagnosing the OBDII Error Code P0300

Diagnosing a P0300 error code systematically is key to pinpointing the underlying cause. Here’s a step-by-step diagnostic approach:

Using a Scan Tool

The first step in diagnosing a P0300 code is to use an OBDII scan tool. Connect the scan tool to your vehicle’s diagnostic port and retrieve all stored trouble codes. While P0300 indicates a random misfire, checking for additional codes is crucial. Are there any codes indicating misfires in specific cylinders (P0301-P030n)? Are there codes related to fuel delivery, ignition system, or vacuum leaks? These additional codes can provide valuable clues.

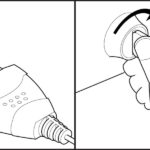

Inspecting Spark Plugs, Ignition Coils, and Fuel Injectors

Visually inspect the spark plugs. Check for wear, damage, carbon fouling, or oil fouling. Compare the condition of spark plugs from different cylinders. Next, test the ignition coils. This can be done using a multimeter to check resistance or by using a spark tester to verify spark delivery. You can also listen for clicking sounds from the fuel injectors using a stethoscope or by carefully touching them while the engine is running to feel for pulsations, indicating they are firing. However, for a more thorough assessment of fuel injector performance, professional cleaning and flow testing might be necessary.

Performing a Compression Test

A compression test can help determine if a mechanical issue, such as a cylinder with low compression, is contributing to the misfire. Low compression in a cylinder can be due to worn piston rings, valve problems, or a cylinder head gasket leak. Perform a compression test on all cylinders and compare the readings. Significant variation between cylinders can indicate a mechanical problem.

Checking for Vacuum and Exhaust Leaks

Inspect all vacuum lines and connections for cracks, breaks, or disconnections. Use a vacuum gauge or a smoke tester to identify vacuum leaks. Similarly, check the exhaust system for leaks, especially around exhaust manifolds, gaskets, and pipes, paying close attention to areas near oxygen sensors.

Evaluating Fuel Pressure and Timing

Use a fuel pressure gauge to check if the fuel pressure is within the manufacturer’s specified range. If fuel pressure is low, investigate the fuel pump, fuel filter, and fuel pressure regulator. Assess the engine timing. Check the condition of the timing belt or chain and inspect the crankshaft and camshaft position sensors for proper function.

How to Fix the OBDII Error Code P0300

The repair strategy for a P0300 code depends entirely on the underlying cause identified during the diagnostic process. Here are common fixes:

Replacing Spark Plugs and Ignition Coils

If worn spark plugs or faulty ignition coils are identified as the issue, replacement is necessary. Replace spark plugs according to the vehicle manufacturer’s recommended intervals and use the correct type of spark plugs. When replacing ignition coils, consider replacing them in sets, especially if the vehicle has high mileage.

Fuel Injector Service or Replacement

If clogged fuel injectors are suspected, professional fuel injector cleaning or replacement may be required. In some cases, fuel injector cleaner additives can be used, but for severe clogging, removal and professional cleaning or replacement is more effective.

Repairing Vacuum and Exhaust Leaks

Locate and repair any vacuum leaks by replacing damaged vacuum lines, gaskets, or components. Similarly, repair exhaust leaks by replacing gaskets, welding cracks, or replacing damaged exhaust components.

Addressing Timing Issues

If timing issues are identified, correct the engine timing according to the manufacturer’s specifications. This may involve replacing a stretched timing chain or worn timing belt or addressing issues with timing sensors.

Cylinder Head Gasket Replacement

If a cylinder head gasket failure is diagnosed, this is a more complex repair requiring the removal of the cylinder head and replacement of the gasket. It’s crucial to ensure proper cylinder head resurfacing and torqueing during reassembly.

Once the necessary repairs are completed, clear the OBDII error codes using a scan tool and test drive the vehicle to ensure the P0300 code does not return and that the engine is running smoothly. Regular maintenance, including timely spark plug replacement and fuel system cleaning, can help prevent future misfires and maintain optimal engine performance.

By following these diagnostic and repair steps, you can effectively address the eobd/obdii error-p0300 and ensure your vehicle operates reliably and efficiently.