Seeing your check engine light illuminate on your dashboard can be a moment of concern for any driver. It’s a signal that something isn’t quite right with your vehicle, but without further investigation, the cause remains a mystery. This is where understanding DTC OBDII DTC, or Diagnostic Trouble Codes, becomes invaluable. While the check engine light simply alerts you to a problem, DTCs pinpoint exactly what the issue is, empowering you to take informed action.

This guide will delve into the world of DTCs, explaining what they are, where they originate, and how to decipher them. Whether you’re a car enthusiast, a fleet manager overseeing a vehicle pool, or simply a driver wanting to be more informed about your car’s health, understanding DTC OBDII DTC codes is a crucial step towards proactive vehicle maintenance and avoiding costly repairs.

What are DTC OBDII DTC Codes?

DTC stands for Diagnostic Trouble Code. These alphanumeric codes are essentially the language your vehicle’s onboard computer uses to communicate when it detects a problem. Think of them as error messages from your car. The “OBDII” part refers to the On-Board Diagnostics II system, which is the standardised system used in most cars and light trucks manufactured after 1996. Therefore, when we talk about DTC OBDII DTC, we are often referring to these standardised diagnostic trouble codes accessed via the OBD-II system.

When a malfunction occurs in your vehicle, sensors throughout the car detect the anomaly. This information is relayed to the engine control unit (ECU) or powertrain control module (PCM), the car’s central computer. If the issue is significant enough, the ECU will trigger the check engine light and store a corresponding DTC in its memory. This DTC acts as a specific identifier for the problem, allowing mechanics and informed drivers to diagnose the issue effectively.

Where Do DTCs Come From?

DTCs are generated by your vehicle’s On-Board Diagnostics (OBD) system. This system is constantly monitoring various components and systems within your car, from the engine and transmission to the emissions system and brakes. The OBD system’s primary function is to ensure your vehicle is running efficiently and meeting emission standards.

Over time, OBD systems have evolved. Early systems, known as OBD-I, were manufacturer-specific and lacked standardization. However, the introduction of OBD-II brought about a universal standard for diagnostic codes. This standardisation was largely driven by environmental regulations and the need for consistent vehicle diagnostics across different makes and models.

Today, OBD-II is the dominant standard for light- and medium-duty vehicles. For heavy-duty vehicles and equipment, the J1939 standard is commonly used. Both systems serve the same fundamental purpose – to detect and report vehicle malfunctions through DTCs – but they differ in their communication protocols and specific code structures.

- OBD-II: Predominantly used in cars and light trucks, especially those sold in the United States after 1996. It provides a standardised set of DTCs and a universal diagnostic port.

- J1939: The standard for most heavy-duty diesel vehicles and equipment. It uses a different communication network (CAN bus) and has its own structure for DTCs.

If you’re unsure which standard your vehicle adheres to, consulting your owner’s manual or contacting your dealership is always recommended.

Mechanic using OBD-II scanner to diagnose DTC codes in a car

Mechanic using OBD-II scanner to diagnose DTC codes in a car

Decoding OBD-II DTC Structure: Reading the Five Characters

OBD-II DTC codes are composed of five characters – one letter followed by four digits. Each character provides crucial information about the nature and location of the fault. Understanding this structure can empower you to gain a preliminary understanding of the issue before even consulting a mechanic.

Let’s break down each character:

1. First Character: System Designation

The first letter indicates the primary system affected by the fault:

- P (Powertrain): Relates to the engine, transmission, fuel system, and associated components. Powertrain codes are the most frequent type of DTC you’ll encounter.

- C (Chassis): Indicates issues with mechanical systems outside the passenger compartment, such as steering, suspension, braking (ABS), and traction control.

- B (Body): Refers to components mainly located within the passenger compartment, including airbags, power windows, air conditioning, and central locking.

- U (Network or Undefined): Signals communication issues within the vehicle’s computer network. These codes often point to problems with the Controller Area Network (CAN bus) or other communication protocols between different modules.

2. Second Character: Code Type

The second character, a digit, specifies whether the code is generic or manufacturer-specific:

- 0 (Generic): Indicates a standardised SAE (Society of Automotive Engineers) code. These codes are common across all OBD-II compliant vehicles, regardless of make or model.

- 1 (Manufacturer-Specific): Signifies a code defined by the specific vehicle manufacturer. These codes address issues unique to a particular make or model and may require manufacturer-specific diagnostic tools for in-depth interpretation.

- 2 or 3 (Manufacturer-Specific or Reserved): While less common, ‘2’ or ‘3’ in the second position usually also denotes a manufacturer-specific code. The exact meaning can be highly dependent on the preceding letter and the vehicle manufacturer’s documentation.

3. Third Character: Subsystem Identification

The third character, a digit ranging from 1 to 8, identifies the specific subsystem within the broader system (indicated by the first letter) where the fault lies:

- 1: Fuel and Air Metering System (e.g., issues with oxygen sensors, mass air flow sensor, fuel trim)

- 2: Fuel and Air Metering Injection System (e.g., fuel injector problems)

- 3: Ignition System or Misfire (e.g., spark plug issues, ignition coil faults)

- 4: Auxiliary Emission Controls System (e.g., EVAP system leaks, catalytic converter inefficiency)

- 5: Vehicle Speed Controls and Idle Control System (e.g., idle speed issues, cruise control malfunctions)

- 6: Computer Output Circuit (e.g., problems with sensors or actuators controlled by the ECU)

- 7: Transmission (e.g., automatic transmission issues – applicable for Powertrain ‘P’ codes)

- 8: Transmission (e.g., automatic transmission issues – applicable for Powertrain ‘P’ codes)

4 & 5. Fourth and Fifth Characters: Fault Index

The fourth and fifth characters, read together as a two-digit number from 00 to 99, represent the specific fault index. This number pinpoints the exact nature of the malfunction within the identified subsystem. For example, within the “Fuel and Air Metering System” (third character ‘1’), different two-digit fault indices would indicate specific problems like “Oxygen Sensor Circuit Low Voltage (Bank 1, Sensor 1)” or “Mass Air Flow Sensor Circuit Range/Performance Problem.”

To fully understand a DTC, consulting a reliable DTC code database, your vehicle’s repair manual, or a professional mechanic is crucial. These resources will provide the precise definition of the five-character code and guide you toward effective troubleshooting.

Interpreting DTC OBDII DTC Codes: An Example

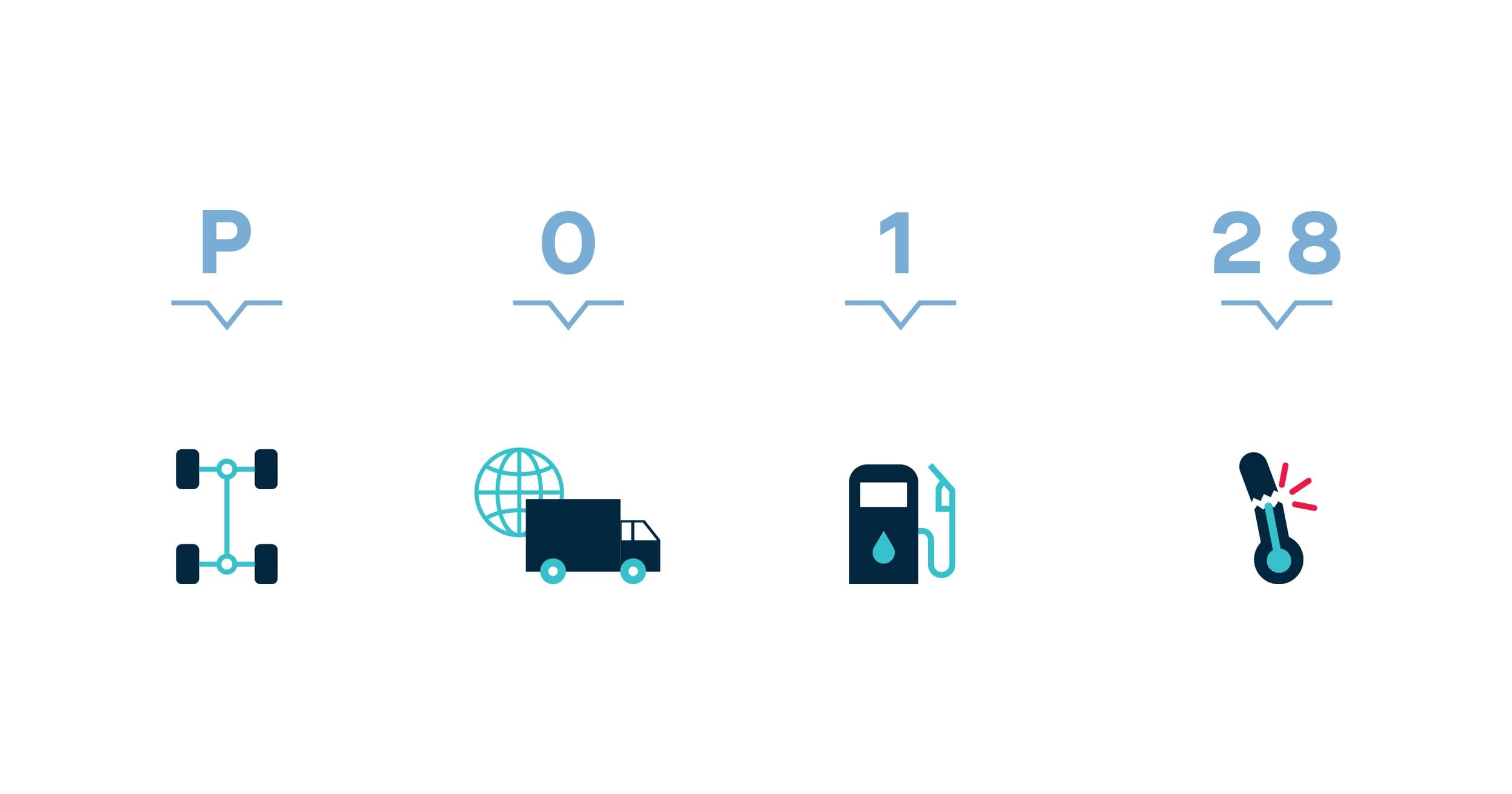

Let’s take the common DTC P0128 as an example and break it down using our newfound knowledge:

- P: Indicates the issue is within the Powertrain system, likely related to the engine or transmission.

- 0: Signifies a generic, standardised SAE code, meaning it’s not manufacturer-specific and its definition is universally applicable across OBD-II vehicles.

- 1: Points to the Fuel and Air Metering System as the specific subsystem at fault.

- 28: This fault index, combined with the preceding characters, reveals the precise issue: “Coolant Thermostat (Coolant Temperature Below Thermostat Regulating Temperature).”

Therefore, DTC P0128 indicates that the engine coolant temperature is not reaching the expected operating temperature within a reasonable timeframe, likely due to a thermostat malfunction.

Common OBDII DTC Codes You Might Encounter

While there are thousands of possible DTCs, some are more frequently encountered than others. Being familiar with these common codes can provide a quicker initial diagnosis. Here are a few examples:

- P0442: Evaporative Emission Control System Leak Detected (Small Leak): Indicates a minor leak in the EVAP system, which prevents fuel vapours from escaping into the atmosphere.

- P0606: PCM/ECM Processor Fault: Signals a malfunction within the Powertrain Control Module (PCM) or Engine Control Module (ECM) – the car’s main computer.

- P0101: Mass Air Flow (MAF) Sensor Circuit Range/Performance Problem: Points to an issue with the MAF sensor, which measures the airflow entering the engine.

- P0110: Intake Air Temperature Sensor Circuit Malfunction: Indicates a problem with the sensor that measures the temperature of the air entering the engine.

- P0500: Vehicle Speed Sensor Malfunction: Signals an issue with the sensor that measures the vehicle’s speed.

- P0706: Transmission Range Sensor Circuit Range/Performance: Indicates a problem with the sensor that detects the selected gear in an automatic transmission.

It’s important to remember that while DTCs are highly informative, they only point to the symptom of a problem, not necessarily the root cause. Further diagnosis by a qualified mechanic is often necessary to pinpoint the underlying issue and implement a proper repair.

J1939 DTCs: Diagnostics for Heavy-Duty Vehicles

While OBD-II dominates light-duty vehicle diagnostics, heavy-duty vehicles and equipment often utilise the J1939 standard. J1939 DTCs have a different structure compared to OBD-II codes, reflecting the more complex systems found in trucks, buses, and construction equipment.

A J1939 DTC comprises four key fields:

- Suspect Parameter Number (SPN): This numerical code identifies the specific parameter or component that is experiencing the fault. Each SPN corresponds to a particular sensor, actuator, or system within the vehicle.

- Failure Mode Identifier (FMI): The FMI code indicates the type of fault that has occurred with the SPN. FMIs describe the nature of the problem, such as “Data Valid But Above Normal Operational Range,” “Data Valid But Below Normal Operational Range,” “Sensor Circuit Shorted to High Source,” or “Incorrect Update Rate.”

- Occurrence Counter (OC): This counter tracks how many times a specific fault condition has occurred for a given SPN. The OC value persists even if the fault is no longer active, providing a historical record of intermittent issues.

- SPN Conversion Method (CM): This field defines the byte alignment within the DTC message. It essentially specifies how the SPN, FMI, and OC are arranged within the data packet.

Understanding J1939 DTCs requires access to J1939 documentation and specialised diagnostic tools designed for heavy-duty vehicles.

Leveraging DTC Scan Tools and Telematics for Efficient Diagnostics

For individual vehicle owners, handheld OBD-II scanners are readily available and affordable. These tools plug into your vehicle’s OBD-II port and allow you to read and clear DTCs yourself. However, for fleet managers overseeing multiple vehicles, manually scanning each vehicle becomes impractical and inefficient.

This is where telematics solutions, like Samsara, offer a significant advantage. Telematics systems integrate directly with a vehicle’s OBD-II or J1939 port and automatically collect vehicle data, including DTCs, in real-time. This data is then transmitted to a cloud-based dashboard, providing fleet managers with instant visibility into the health of their entire fleet.

Benefits of using telematics for DTC management include:

- Remote DTC Monitoring: Fleet managers can monitor DTCs across their entire fleet from a central dashboard, without needing to physically access each vehicle.

- Proactive Maintenance Alerts: Telematics systems can be configured to send automated alerts when critical DTCs are detected, enabling proactive maintenance scheduling and preventing breakdowns.

- Faster Diagnostics and Repair: By quickly identifying DTCs, fleet managers can expedite the diagnostic process and get vehicles repaired and back on the road faster.

- Reduced Downtime and Costs: Proactive maintenance based on DTC data helps minimise vehicle downtime and reduces the risk of costly emergency repairs.

Conclusion: Empowering Vehicle Maintenance with DTC OBDII DTC Knowledge

Understanding DTC OBDII DTC codes is no longer just for mechanics. For drivers and fleet operators alike, grasping the basics of diagnostic trouble codes offers significant benefits. It empowers you to understand your vehicle’s health, communicate effectively with mechanics, and make informed decisions about vehicle maintenance.

Telematics solutions further enhance this understanding, particularly for fleet management, by providing real-time DTC monitoring and proactive maintenance capabilities. By embracing DTC knowledge and leveraging available tools, you can ensure your vehicles remain in optimal condition, reducing downtime, saving costs, and promoting safer, more efficient operations.

To explore how telematics can streamline your DTC management and fleet maintenance, consider exploring solutions like Samsara and discover how they can transform your approach to vehicle health and performance.