After replacing a seized wiper mechanism on an Audi A8 4E, the wipers functioned correctly. However, a question arose concerning a procedure to set the wiper distance to the A-pillar using VCDS. This article explores this procedure and whether VCDS can be used as an alternative to the VAS system.

Understanding Wiper Alignment with VCDS

The Audi A8 4E’s wiper motor ECU (J400) operates as a slave to the Central Electric I (J519) module, address 0x09. The J400 module had a coding of 00000030. Attempts to modify this coding were unsuccessful, raising doubts about its relation to the A-pillar distance setting.

The official VAS procedure for setting the distance to the A-pillar involves specific steps:

-

Reference Position: The wiper motor must be in its reference position. This is achieved by activating the windscreen wiper switch (e.g., single wipe) after installation and ensuring the wiper arms are correctly fitted. The wiper switch should be in its basic setting (-0-).

-

VAS Navigation: Navigate through the VAS 5051 system to: Body (Rep.Gr. 01; 27; 50 – 97)/Electrical system (Rep.Gr. 01; 27; 90 – 97)/01 – Self-diagnosis compatible systems/09 – Electronic central electrics (Rep.Gr. 97)/J400 – Wiper motor control unit, Functions/J400 – Replacing (Rep.Gr.-92)

-

Control Unit Information: The VAS system displays the control unit version and coding of the J400 module.

-

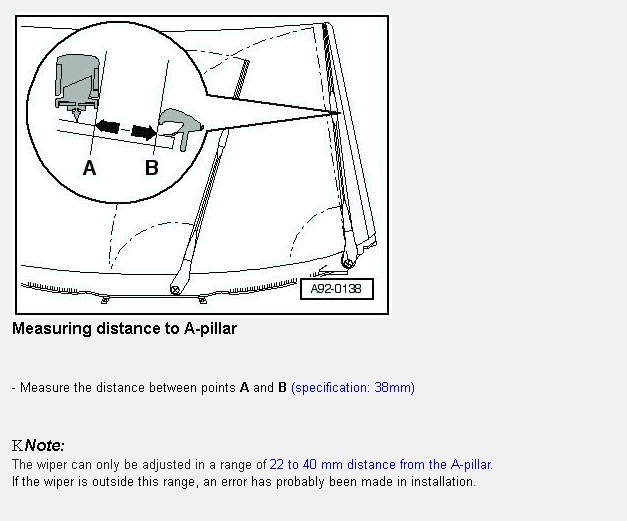

Upper Reverse Point: Select the “wiper upper reverse point” control element to move the wiper to its upper reverse position. Measure the distance from the A-pillar to the driver-side wiper hinge. This measurement is crucial for the subsequent coding process.

-

Recoding J400: Input the measured distance into the VAS system to recode the J400 module. The new value will be displayed along with the previous value in brackets.

-

Verification: If the recoded value doesn’t match the specification of 36 ± 2mm, re-measure and repeat the coding process.

Wiper Mechanism

Wiper Mechanism

The VAS procedure includes system limitations: only five coding attempts are allowed before a terminal 15 reset (ignition off/on) is required. Coding is rejected if the “move to upper reverse point” test isn’t performed.

VCDS and Wiper Alignment: Possibilities and Limitations

While the VAS procedure is clearly defined, using VCDS for this specific task remains unclear. The inability to modify the J400 coding via VCDS suggests this functionality might be exclusive to the VAS system. Further research into VCDS capabilities or consulting with Ross-Tech, the developers of VCDS, may provide a definitive answer.

Conclusion: The Role of VCDS in Wiper Setup

Although VCDS is a powerful diagnostic tool for VAG vehicles, its ability to perform the specific A-pillar distance adjustment for the Audi A8 4E’s wipers remains uncertain. The provided coding data from a full vehicle scan using VCDS (version 16.8.1.3) highlights the J400 module and its coding (00000030) within the Central Electrics system (address 0x09). However, without explicit documentation or successful coding modification attempts, utilizing VCDS for this procedure is not confirmed. The VAS system, with its dedicated test program and coding access, remains the verified method for this specific wiper alignment task.