Is your TDI engine giving you a hard time starting? Are you struggling to pinpoint the cause? The Vcds Measuring Block Tdi is your go-to solution for advanced diagnostics. This guide, brought to you by CARDIAGTECH.NET, will help you understand how to use VCDS to measure and interpret crucial data, identify potential issues, and keep your TDI engine running smoothly. We’ll cover fuel rail pressure testing, common problems, and how CARDIAGTECH.NET can provide the tools you need for effective troubleshooting.

1. Understanding VCDS and TDI Engines

1.1 What is VCDS?

VCDS (VAG-COM Diagnostic System) is a comprehensive diagnostic tool specifically designed for Volkswagen Audi Group (VAG) vehicles, including VW, Audi, Skoda, and SEAT. It allows you to access and analyze data from various control modules within your car, offering insights far beyond basic OBD-II scanners. VCDS provides functionalities like reading fault codes, performing output tests, and, most importantly for our focus, accessing measuring blocks. This tool can help enhance your automotive service offerings.

1.2 The Importance of Measuring Blocks

Measuring blocks, also known as live data or data logging, display real-time information from sensors and systems within your vehicle. These blocks are essential for diagnosing intermittent issues, verifying sensor readings, and assessing the overall health of your engine. For TDI engines, measuring blocks provide crucial data about fuel pressure, air intake, turbocharger performance, and more.

1.3 Why TDI Engines Need Special Attention

TDI (Turbocharged Direct Injection) engines are known for their fuel efficiency and robust performance. However, their complex design, which includes high-pressure fuel systems and sensitive emission control components, requires precise diagnostics. Using VCDS measuring blocks allows you to monitor these systems effectively, ensuring optimal performance and longevity of your TDI engine. Regular monitoring can enhance your automotive service offerings.

2. Identifying the Need for Fuel Rail Pressure Testing

2.1 Common Symptoms of Fuel Pressure Issues

Several symptoms can indicate fuel pressure problems in your TDI engine. Recognizing these signs early can prevent more significant damage and costly repairs:

- Hard Starting: The engine takes longer than usual to start, especially after sitting for a while.

- Rough Idle: The engine idles unevenly or roughly, often accompanied by vibrations.

- Stalling: The engine stalls unexpectedly, particularly at low speeds or when coming to a stop.

- Loss of Power: Noticeable reduction in acceleration and overall engine power.

- Poor Fuel Economy: A decrease in fuel efficiency without any apparent reason.

- Check Engine Light: Illumination of the check engine light, possibly with codes related to fuel pressure.

2.2 The Role of Fuel Rail Pressure

Fuel rail pressure is the pressure at which fuel is delivered to the injectors. Maintaining the correct fuel rail pressure is crucial for proper combustion and engine performance. If the pressure is too low, the engine may struggle to start or run smoothly. If it’s too high, it can damage injectors and other fuel system components.

2.3 The Importance of Diagnosing Early

Addressing fuel pressure issues promptly can prevent further damage to your TDI engine. Delaying diagnosis and repair can lead to:

- Injector Damage: Incorrect fuel pressure can cause injectors to malfunction or fail.

- High-Pressure Fuel Pump Failure: The pump may have to work harder to compensate for pressure loss, leading to premature failure.

- Catalytic Converter Damage: Improper combustion can result in unburned fuel entering the exhaust system, damaging the catalytic converter.

- Engine Damage: In severe cases, prolonged fuel pressure issues can cause engine damage due to improper combustion.

3. Preparing for VCDS Measuring Block TDI Testing

3.1 Essential Tools and Equipment

Before you start, ensure you have the necessary tools and equipment:

- VCDS Interface: A genuine VCDS interface cable and software.

- Laptop: A laptop with VCDS software installed and a stable connection to the VCDS interface.

- Vehicle Information: Your vehicle’s year, make, model, and engine code (e.g., CJAA).

- Repair Manual: A repair manual specific to your vehicle model, providing torque specifications and component locations.

- Safety Gear: Safety glasses, gloves, and appropriate clothing.

3.2 Locating the Fuel Rail and Components

Before diving into VCDS, familiarize yourself with the location of the fuel rail, fuel pressure regulator, and injectors in your TDI engine. This knowledge will help you interpret the data you gather during testing:

- Fuel Rail: Typically located on top of the engine, connecting the injectors.

- Fuel Pressure Regulator: Often found on the fuel rail or high-pressure fuel pump.

- Injectors: Attached to the fuel rail, delivering fuel directly into the combustion chambers.

3.3 Ensuring Vehicle Safety

Safety should always be your top priority. Follow these precautions:

- Work Area: Ensure your work area is well-ventilated and free of flammable materials.

- Fuel Handling: Be cautious when working with fuel, as it is highly flammable. Avoid sparks or open flames.

- Battery Disconnect: Disconnect the negative battery terminal to prevent electrical shorts.

- Personal Protection: Wear safety glasses and gloves to protect your eyes and skin.

4. Step-by-Step Guide to Using VCDS for Fuel Rail Pressure Testing

4.1 Connecting VCDS to Your Vehicle

- Connect Interface: Plug the VCDS interface cable into the OBD-II port of your vehicle.

- Turn On Ignition: Turn the ignition key to the “ON” position, but do not start the engine.

- Launch VCDS: Open the VCDS software on your laptop.

- Select Control Module: Click “Select Control Module” on the main screen.

- Choose Engine: Select “01-Engine” from the list of control modules.

4.2 Navigating to Measuring Blocks

- Basic Settings: Click “Measuring Blocks – 08” or “Advanced Measuring Values”. The option may vary depending on your VCDS version and vehicle.

- Identify Fuel Pressure Groups: Look for measuring blocks related to fuel pressure. Common groups include 106, 140, 141, and 230, though availability may vary by engine type.

4.3 Interpreting the Data

- Monitor Fuel Pressure: Observe the fuel rail pressure readings in the selected measuring blocks.

- Compare to Specifications: Compare the readings to the specifications in your repair manual. The typical fuel rail pressure for a TDI engine ranges from 300 to 1800 bar (4350 to 26100 psi), depending on the engine load and operating conditions.

- Analyze Deviations: Note any significant deviations from the specified range. Low pressure may indicate a leak or pump issue, while high pressure may suggest a regulator problem.

4.4 Troubleshooting Based on VCDS Readings

Based on the fuel rail pressure readings, you can narrow down potential causes:

- Low Fuel Pressure:

- Fuel Filter: Check for a clogged fuel filter.

- Fuel Pump: Inspect the fuel pump for proper operation.

- Fuel Pressure Regulator: Test the fuel pressure regulator for leaks or malfunctions.

- Injectors: Check the injectors for leaks or blockages.

- High Fuel Pressure:

- Fuel Pressure Regulator: Replace the fuel pressure regulator if it is faulty.

- Fuel Pump Control Module: Check the fuel pump control module for proper function.

- Fluctuating Fuel Pressure:

- Fuel Pressure Sensor: Check the fuel pressure sensor for accuracy.

- Wiring Issues: Inspect the wiring and connectors related to the fuel system for damage or corrosion.

5. Specific VCDS Measuring Block TDI Examples

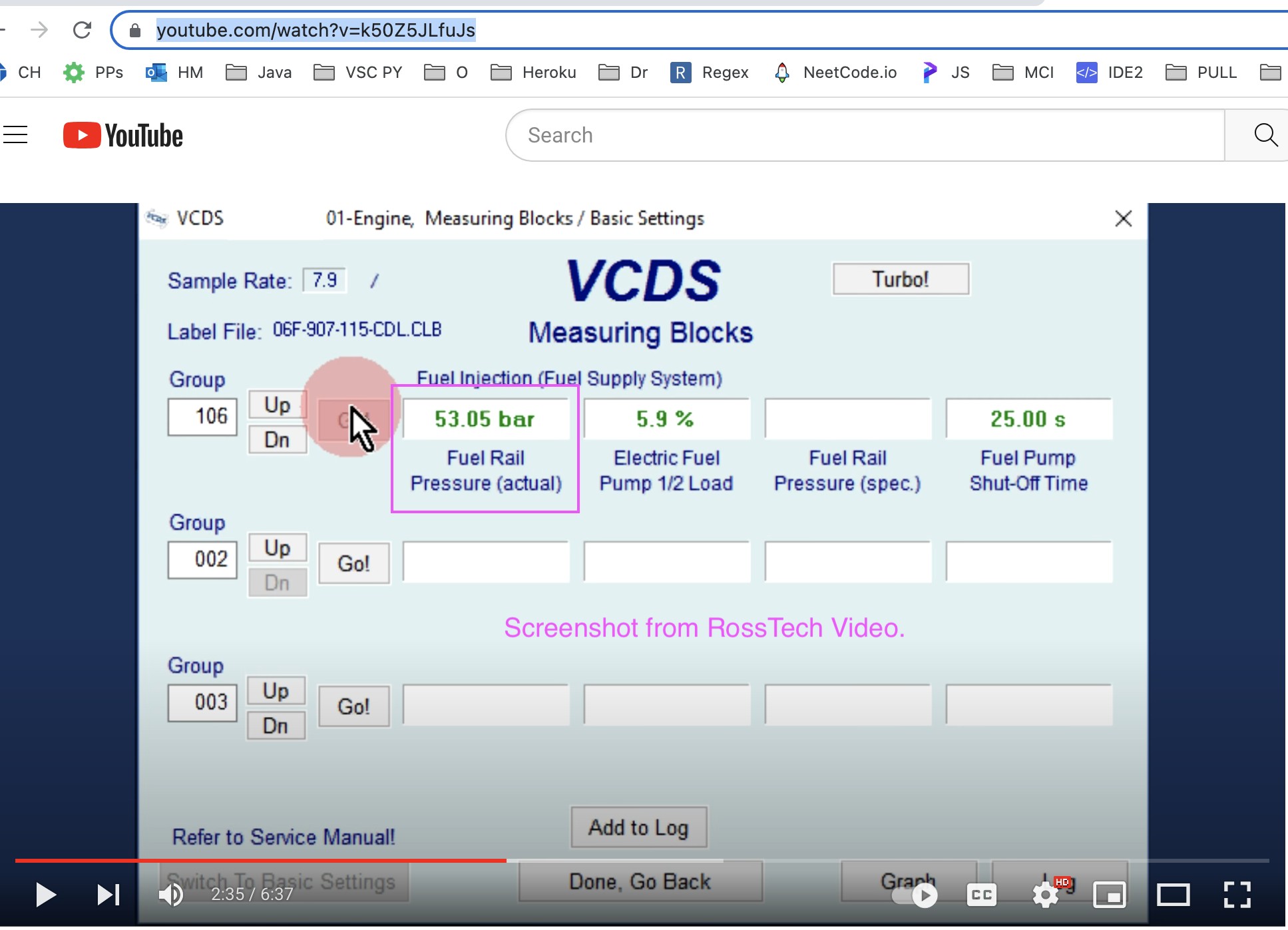

5.1 Group 106: Fuel Rail Pressure

Group 106 is one of the primary groups to check for fuel rail pressure. It should display the actual fuel rail pressure in bar or MPa. However, as seen in the original question, this group may not always provide the expected data for all TDI models.

Alternative Text: VCDS interface showing fuel rail pressure readings in group 106, used for diagnosing TDI engine issues.

5.2 Group 140 and 141: Injection Quantity Deviation

These groups show injection quantity deviation, which can indirectly indicate fuel pressure issues. Large deviations may suggest problems with specific injectors or overall fuel delivery.

Alternative Text: VCDS screenshot displaying absolute pressure in group 141, relevant to fuel system diagnostics for TDI engines.

5.3 Advanced Measuring Blocks: Custom Data Selection

If you cannot find specific fuel pressure data in standard measuring blocks, use the “Advanced Measuring Blocks” function. This allows you to select individual sensors and parameters to monitor. Search for terms like “fuel pressure,” “rail pressure,” or “fuel rail.”

Alternative Text: Advanced measuring block options in VCDS showing fuel-related parameters for detailed TDI engine diagnostics.

5.4 Utilizing VCDS Charts and Graphs

VCDS allows you to chart and graph data in real-time, providing a visual representation of fuel pressure changes over time. This can be extremely helpful in identifying intermittent issues or correlating fuel pressure drops with specific engine conditions.

- Select Measuring Blocks: Choose the fuel pressure measuring blocks you want to monitor.

- Start Logging: Click “Start” to begin data logging.

- Drive or Simulate Conditions: Drive the vehicle or simulate conditions that trigger the issue (e.g., hard starting).

- Stop Logging: Click “Stop” to end data logging.

- View Graph: VCDS will display a graph of the data, allowing you to analyze trends and identify anomalies.

6. Common Problems and Solutions

6.1 Fuel Filter Issues

A clogged fuel filter can restrict fuel flow and cause low fuel pressure. Replace the fuel filter according to the manufacturer’s recommendations, typically every 20,000 to 40,000 miles.

6.2 Fuel Pump Malfunctions

The fuel pump may fail to deliver adequate fuel pressure due to wear, damage, or electrical issues. Use VCDS to monitor the fuel pump control module and check for fault codes related to the fuel pump.

6.3 Fuel Pressure Regulator Problems

A faulty fuel pressure regulator can cause either low or high fuel pressure. Test the regulator using VCDS and a multimeter, and replace it if necessary.

6.4 Injector Leaks or Blockages

Leaking or blocked injectors can disrupt fuel delivery and cause rough running or starting issues. Perform an injector balance test using VCDS to identify problematic injectors.

6.5 Wiring and Electrical Issues

Damaged wiring, corroded connectors, or grounding problems can affect fuel system components. Inspect the wiring and connectors related to the fuel pump, fuel pressure regulator, and injectors.

7. Advanced VCDS Techniques

7.1 Performing Output Tests

VCDS output tests allow you to activate individual components to verify their functionality. For example, you can activate the fuel pump to check its operation or cycle the fuel pressure regulator to observe its response.

- Select Control Module: Choose “01-Engine” in VCDS.

- Output Tests: Click “Output Tests – 03”.

- Select Component: Choose the component you want to test (e.g., fuel pump, fuel pressure regulator).

- Run Test: Follow the on-screen instructions to run the test.

7.2 Adaptations and Basic Settings

VCDS adaptations and basic settings allow you to adjust certain parameters within the engine control unit (ECU). These functions can be used to reset fuel pump adaptations, calibrate sensors, or perform other maintenance tasks.

- Select Control Module: Choose “01-Engine” in VCDS.

- Adaptation – 10 or Basic Settings – 04: Click either option, depending on the task.

- Select Channel or Group: Choose the channel or group you want to adapt or adjust.

- Enter New Value: Enter the new value or follow the on-screen instructions.

- Save Changes: Save the changes to the ECU.

7.3 Reading and Clearing Fault Codes

Regularly check for fault codes related to the fuel system. Clearing these codes after addressing the underlying issues can help ensure proper engine operation and prevent future problems.

- Select Control Module: Choose “01-Engine” in VCDS.

- Fault Codes – 02: Click “Fault Codes – 02”.

- Read Codes: VCDS will display any stored fault codes.

- Clear Codes: After addressing the issues, click “Clear Codes” to erase the fault codes.

8. The Role of CARDIAGTECH.NET

8.1 Providing High-Quality Diagnostic Tools

CARDIAGTECH.NET is committed to providing top-of-the-line diagnostic tools, including VCDS interfaces and related equipment. Our products are designed to meet the needs of both professional technicians and DIY enthusiasts. With CARDIAGTECH.NET, you can be confident in the accuracy and reliability of your diagnostic processes.

8.2 Expert Support and Guidance

We understand that using diagnostic tools can be challenging. That’s why CARDIAGTECH.NET offers expert support and guidance to help you get the most out of your VCDS interface. Our team of experienced technicians is available to answer your questions and provide assistance with troubleshooting.

8.3 Enhancing Your Automotive Service Offerings

By partnering with CARDIAGTECH.NET, you can enhance your automotive service offerings and provide your customers with superior diagnostic capabilities. Our tools and support enable you to accurately diagnose and repair TDI engine issues, increasing customer satisfaction and loyalty.

9. Real-World Case Studies

9.1 Case Study 1: Hard Starting Issue

Problem: A 2012 VW Jetta SportWagen TDI (CJAA engine) experienced hard starting, especially after sitting overnight. No fault codes were present.

Diagnosis: Using VCDS, the technician monitored fuel rail pressure during startup. The pressure was significantly lower than the specified range.

Solution: Further inspection revealed a leaking fuel pressure regulator. Replacing the regulator resolved the hard starting issue.

9.2 Case Study 2: Loss of Power and Poor Fuel Economy

Problem: A 2015 Audi A3 TDI experienced a loss of power and poor fuel economy. The check engine light was illuminated with a fault code related to fuel pressure.

Diagnosis: VCDS data logging showed fluctuating fuel pressure during acceleration.

Solution: The fuel pressure sensor was found to be faulty. Replacing the sensor restored proper fuel pressure and resolved the performance issues.

9.3 Case Study 3: Rough Idle and Stalling

Problem: A 2010 VW Golf TDI had a rough idle and stalled frequently.

Diagnosis: VCDS injector balance test revealed that one injector was significantly deviating from the others.

Solution: The faulty injector was replaced, which eliminated the rough idle and stalling problems.

10. Maintaining Your TDI Engine for Optimal Performance

10.1 Regular Fuel System Inspections

Perform routine fuel system inspections to identify potential issues before they escalate. Check for leaks, corrosion, and damage to fuel lines, connectors, and components.

10.2 Using High-Quality Fuel

Use high-quality diesel fuel from reputable sources. Avoid using fuel that may be contaminated with water or other impurities.

10.3 Following Maintenance Schedules

Adhere to the manufacturer’s recommended maintenance schedules for fuel filter replacements, injector cleaning, and other fuel system services.

10.4 Staying Updated with Diagnostic Techniques

Continuously update your knowledge of diagnostic techniques and tools. Attend training seminars, read technical publications, and stay informed about the latest advancements in automotive technology.

11. FAQs About VCDS Measuring Block TDI

11.1 What is the typical fuel rail pressure for a TDI engine?

The typical fuel rail pressure for a TDI engine ranges from 300 to 1800 bar (4350 to 26100 psi), depending on the engine load and operating conditions.

11.2 Can VCDS be used on all TDI engines?

VCDS is compatible with most Volkswagen Audi Group (VAG) vehicles, including VW, Audi, Skoda, and SEAT TDI engines. However, compatibility may vary depending on the year and model of the vehicle.

11.3 How often should I check fuel rail pressure with VCDS?

It is recommended to check fuel rail pressure with VCDS during routine maintenance or when experiencing symptoms of fuel system issues.

11.4 What does a low fuel pressure reading indicate?

A low fuel pressure reading may indicate a clogged fuel filter, a faulty fuel pump, a leaking fuel pressure regulator, or leaking injectors.

11.5 What does a high fuel pressure reading indicate?

A high fuel pressure reading may indicate a faulty fuel pressure regulator or a problem with the fuel pump control module.

11.6 How do I perform an injector balance test with VCDS?

To perform an injector balance test, select “01-Engine” in VCDS, then go to “Measuring Blocks” and look for groups related to injector deviation or balance. Monitor the readings to identify injectors that are significantly deviating from the others.

11.7 Can I use VCDS to calibrate the fuel pressure sensor?

Yes, VCDS can be used to calibrate the fuel pressure sensor through the “Adaptation” or “Basic Settings” functions. Refer to your vehicle’s repair manual for specific instructions.

11.8 What safety precautions should I take when working with fuel systems?

When working with fuel systems, ensure your work area is well-ventilated, avoid sparks or open flames, disconnect the negative battery terminal, and wear safety glasses and gloves.

11.9 Where can I find the correct measuring block numbers for my specific TDI engine?

The correct measuring block numbers can be found in your vehicle’s repair manual or by consulting the Ross-Tech Wiki, a valuable resource for VCDS users.

11.10 How can CARDIAGTECH.NET help me with my VCDS diagnostics?

CARDIAGTECH.NET provides high-quality VCDS interfaces, expert support, and guidance to help you accurately diagnose and repair TDI engine issues. Our team is available to answer your questions and provide assistance with troubleshooting.

12. Call to Action

Don’t let fuel system issues hold back your TDI engine’s performance. Equip yourself with the right tools and knowledge to diagnose and resolve problems efficiently. Contact CARDIAGTECH.NET today at our address: 276 Reock St, City of Orange, NJ 07050, United States, or reach us via Whatsapp at +1 (641) 206-8880. Visit our website at CARDIAGTECH.NET to explore our range of diagnostic tools and get expert support. Let CARDIAGTECH.NET help you keep your TDI engine running smoothly and efficiently.