Ignition Coil VCDS testing is essential for pinpointing misfires and ensuring optimal engine performance. CARDIAGTECH.NET offers the tools and expertise to help you diagnose and resolve ignition coil issues efficiently. By understanding VCDS capabilities, you can improve vehicle maintenance and performance.

1. Understanding Ignition Coils and Their Importance

Ignition coils are critical components in modern internal combustion engines. They transform the vehicle’s low-voltage electricity supply into the high voltage needed to create a spark at the spark plugs. This spark ignites the air-fuel mixture within the cylinders, initiating the combustion process that powers the engine.

1.1. The Role of Ignition Coils

Ignition coils act as step-up transformers, converting the 12-volt electrical system voltage to tens of thousands of volts. This high-voltage surge is delivered to the spark plugs, jumping the gap between the electrodes and creating a spark. The precise timing and strength of this spark are vital for efficient combustion and optimal engine performance.

1.2. Common Symptoms of Failing Ignition Coils

When ignition coils start to fail, they can cause a range of symptoms that affect the vehicle’s performance and fuel efficiency. Recognizing these symptoms early can help prevent more significant engine damage. Here’s a detailed look at the common signs of a failing ignition coil:

- Engine Misfires: Misfires are the most common symptom. They occur when the spark plug fails to ignite the air-fuel mixture in one or more cylinders. This leads to a rough-running engine, especially noticeable at idle or during acceleration.

- Rough Idling: A failing ignition coil can cause the engine to idle roughly. The engine may vibrate excessively or feel shaky when stopped.

- Decreased Fuel Efficiency: Inefficient combustion due to a weak or inconsistent spark can lead to poor fuel economy. You may notice that you need to fill up your gas tank more often than usual.

- Check Engine Light: A failing ignition coil often triggers the check engine light. The car’s computer detects the misfires and stores a diagnostic trouble code (DTC).

- Loss of Power: The engine may lack its usual power, especially when accelerating or climbing hills. This is because one or more cylinders are not contributing to the engine’s overall output.

- Engine Stalling: In severe cases, a failing ignition coil can cause the engine to stall, especially at low speeds or when coming to a stop.

- Difficulty Starting: If the ignition coil is not providing enough voltage, it can be difficult to start the engine. The engine may crank for a long time before finally starting, or it may not start at all.

1.3. Factors That Can Cause Ignition Coil Failure

Several factors can contribute to the premature failure of ignition coils. Understanding these factors can help prevent coil failures and maintain your vehicle’s performance.

- Age and Wear: Like all mechanical components, ignition coils have a limited lifespan. Over time, the insulation within the coil can break down, leading to shorts and failures.

- Heat: High engine temperatures can damage the ignition coils. The heat can cause the coil’s internal components to degrade, reducing its ability to generate the necessary voltage.

- Vibration: Constant engine vibration can also contribute to coil failure. The vibrations can cause the coil’s internal wiring to loosen or break.

- Moisture and Corrosion: Moisture and corrosion can damage the coil’s electrical connections, leading to poor performance and eventual failure.

- Spark Plug Issues: Worn or improperly gapped spark plugs can put extra strain on the ignition coils, causing them to overheat and fail prematurely.

- Voltage Spikes: Voltage spikes in the vehicle’s electrical system can damage the ignition coils. These spikes can be caused by faulty alternators or other electrical components.

2. What is VCDS and Why Use It?

VCDS, or VAG-COM Diagnostic System, is a comprehensive diagnostic tool used primarily for Volkswagen, Audi, SEAT, and Škoda vehicles. Developed by Ross-Tech, VCDS allows users to access, diagnose, and program various electronic control units (ECUs) within these vehicles. It provides capabilities far beyond those of generic OBD-II scanners, offering in-depth insights into the vehicle’s systems.

2.1. Key Features of VCDS

- Diagnostic Trouble Codes (DTCs): Read and clear DTCs from all modules in the vehicle.

- Live Data Monitoring: View real-time data from sensors and components.

- Adaptations: Adjust settings and parameters within the ECUs.

- Coding: Enable or disable features, and customize vehicle behavior.

- Actuator Tests: Activate specific components to verify their functionality.

- Service Resets: Reset service reminders and perform maintenance procedures.

2.2. Benefits of Using VCDS for Ignition Coil Testing

Using VCDS for ignition coil testing offers several advantages over traditional methods.

- Pinpoint Accuracy: VCDS can identify the exact cylinder experiencing misfires, which helps narrow down the problem to a specific ignition coil.

- Real-Time Data Analysis: VCDS allows you to monitor the engine’s performance in real-time, providing valuable insights into the ignition system’s behavior.

- Comprehensive Diagnostics: VCDS can access detailed information from the engine control unit (ECU), including misfire counts, ignition timing, and other relevant parameters.

- Cost-Effective: By accurately diagnosing ignition coil issues, VCDS helps prevent unnecessary replacements of other components, saving you time and money.

- Enhanced Troubleshooting: VCDS can perform actuator tests on the ignition coils, allowing you to verify their functionality and identify any potential problems.

2.3. Comparison of VCDS with Other Diagnostic Tools

While there are many diagnostic tools available on the market, VCDS stands out for its in-depth coverage of VAG vehicles and its advanced features. Generic OBD-II scanners can read basic trouble codes, but they often lack the ability to access detailed information or perform advanced functions. Professional-grade scan tools offer more capabilities, but they can be expensive and may not be as specialized for VAG vehicles as VCDS.

| Feature | VCDS | Generic OBD-II Scanner | Professional Scan Tool |

|---|---|---|---|

| Vehicle Coverage | Primarily VAG (VW, Audi, SEAT, Škoda) | All OBD-II compliant vehicles | Wide range of vehicles |

| DTC Reading | Detailed DTCs from all modules | Basic DTCs from engine and transmission only | Detailed DTCs from most modules |

| Live Data | Comprehensive real-time data | Limited real-time data | Extensive real-time data |

| Adaptations | Yes | No | Yes, but often limited |

| Coding | Yes | No | Yes, but often limited |

| Actuator Tests | Yes | No | Yes |

| Service Resets | Yes | No | Yes |

| Cost | Moderate | Low | High |

| Specialization | Highly specialized for VAG vehicles | General purpose | Broad coverage, less specialization |

3. Step-by-Step Guide to Performing a VCDS Ignition Coil Test

To effectively diagnose ignition coil issues using VCDS, follow this detailed step-by-step guide. This process will help you identify misfires, monitor engine performance, and pinpoint faulty ignition coils with precision.

3.1. Connecting VCDS to Your Vehicle

- Gather Your Equipment: Ensure you have a VCDS interface cable and a laptop with the VCDS software installed. CARDIAGTECH.NET offers a range of VCDS tools suitable for your needs.

- Locate the OBD-II Port: Find the OBD-II port in your vehicle. It’s typically located under the dashboard on the driver’s side.

- Connect the Interface Cable: Plug the VCDS interface cable into the OBD-II port.

- Connect to Your Laptop: Connect the other end of the interface cable to a USB port on your laptop.

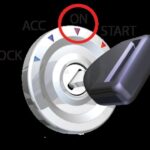

- Turn On the Ignition: Turn the vehicle’s ignition on, but do not start the engine.

- Launch VCDS Software: Open the VCDS software on your laptop.

- Select the Control Module: In VCDS, select the “Select Control Module” option.

- Choose the Engine Module: Choose the engine control module (usually labeled as “01-Engine”).

3.2. Reading Diagnostic Trouble Codes (DTCs)

- Access Fault Codes: Once you’re in the engine control module, click on the “Fault Codes – 02” button.

- Read the Codes: VCDS will scan the ECU for any stored diagnostic trouble codes (DTCs).

- Record the Codes: Note down any DTCs related to misfires or ignition coil issues. Common codes include:

- P0300: Random/Multiple Cylinder Misfire Detected

- P0301-P0312: Cylinder X Misfire Detected (where X is the cylinder number)

- P0351-P0360: Ignition Coil A-J Primary/Secondary Circuit Malfunction

- Clear the Codes (Optional): If you want to clear the codes to see if they reappear, click on the “Clear Codes – 05” button. Be aware that clearing codes will erase any stored diagnostic information.

3.3. Monitoring Live Data for Misfires

- Access Measuring Blocks: In the engine control module, click on the “Measuring Blocks – 08” button.

- Select Misfire Counters: Enter the measuring block numbers that correspond to misfire counters. These numbers vary depending on the vehicle model, but common groups include:

- Groups 014-016: Misfire counters for individual cylinders

- Group 001: Engine speed (RPM) and load

- View Real-Time Data: VCDS will display real-time data for the selected measuring blocks.

- Monitor Misfire Counts: Observe the misfire counts for each cylinder. High misfire counts on a specific cylinder indicate a potential problem with the ignition coil, spark plug, or fuel injector.

- Record Data: Record the misfire counts over a period of time, noting any patterns or trends.

3.4. Performing Output Tests on Ignition Coils

- Access Output Tests: In the engine control module, click on the “Output Tests – 03” button.

- Select Ignition Coil Test: Choose the option to test the ignition coils. VCDS will cycle each ignition coil on and off.

- Listen for Coil Operation: Listen to each ignition coil as it is activated. A healthy coil will produce a distinct clicking sound. A weak or failing coil may sound quieter or not click at all.

- Note Any Anomalies: Record any anomalies, such as coils that don’t click or sound weak.

3.5. Interpreting the Results and Diagnosing the Issue

- Analyze DTCs: Review the diagnostic trouble codes (DTCs) you recorded earlier. DTCs related to misfires or ignition coil malfunctions provide valuable clues about the source of the problem.

- Evaluate Misfire Data: Examine the misfire counts for each cylinder. High misfire counts on a specific cylinder suggest a problem with the ignition system components in that cylinder.

- Assess Output Test Results: Compare the results of the output tests to the misfire data. If a coil sounds weak or doesn’t click during the output test, and the corresponding cylinder has high misfire counts, the ignition coil is likely faulty.

- Consider Other Factors: Keep in mind that misfires can also be caused by other factors, such as:

- Faulty spark plugs

- Fuel injector issues

- Vacuum leaks

- Compression problems

- Perform Additional Tests: If necessary, perform additional tests to rule out other potential causes of misfires. This may include:

- Inspecting the spark plugs

- Testing the fuel injectors

- Checking for vacuum leaks

- Performing a compression test

3.6. Replacing a Faulty Ignition Coil

- Gather Your Tools: Collect the necessary tools for replacing the ignition coil, including:

- New ignition coil

- Socket set

- Wrench set

- Screwdriver

- Torque wrench

- Disconnect the Battery: Disconnect the negative terminal of the battery to prevent electrical shock.

- Locate the Faulty Coil: Identify the faulty ignition coil based on your diagnostic results.

- Disconnect the Electrical Connector: Disconnect the electrical connector from the ignition coil.

- Remove the Coil: Remove the bolt or screws that secure the ignition coil to the engine.

- Install the New Coil: Install the new ignition coil, ensuring it is properly seated and secured.

- Reconnect the Electrical Connector: Reconnect the electrical connector to the ignition coil.

- Reconnect the Battery: Reconnect the negative terminal of the battery.

- Clear DTCs: Use VCDS to clear any stored diagnostic trouble codes (DTCs).

- Test the Engine: Start the engine and monitor its performance. Verify that the misfires are gone and the engine runs smoothly.

Alt Text: A VCDS interface cable connected to a car’s OBD-II port, displaying the VCDS software interface on a laptop screen during an ignition coil test.

4. Advanced VCDS Techniques for Ignition Coil Diagnostics

Beyond basic testing, VCDS offers advanced techniques to fine-tune your ignition coil diagnostics. These methods provide a deeper understanding of your vehicle’s ignition system.

4.1. Using Adaptation Channels for Fine-Tuning

VCDS allows you to adjust various settings within the engine control unit (ECU) through adaptation channels. These channels can be used to fine-tune the ignition system and optimize engine performance.

- Ignition Timing Adjustment: Some vehicles allow you to adjust the ignition timing through adaptation channels. This can be useful for optimizing engine performance based on fuel quality or driving conditions.

- Idle Speed Adjustment: The idle speed can also be adjusted through adaptation channels. This can help smooth out a rough idle caused by a misfiring ignition coil.

- Fuel Trim Adjustment: Fuel trim values can be adjusted to compensate for a lean or rich fuel mixture. This can help improve fuel efficiency and reduce emissions.

Important Note: Adjusting adaptation channels should only be done by experienced technicians who understand the potential consequences. Incorrect settings can damage the engine or cause other problems.

4.2. Utilizing Coding Options for Advanced Diagnostics

VCDS coding options allow you to enable or disable certain features within the ECU. These options can be used for advanced diagnostics, such as disabling individual ignition coils to isolate misfires.

- Disabling Individual Ignition Coils: By disabling one ignition coil at a time, you can determine if a misfire is caused by a specific coil. This can be useful for confirming a diagnosis before replacing the coil.

- Enabling Diagnostic Logging: VCDS allows you to enable diagnostic logging, which records detailed data about the engine’s performance over time. This data can be analyzed to identify intermittent problems or subtle issues that may not be apparent during a static test.

Important Note: Modifying coding options should only be done by experienced technicians who understand the potential consequences. Incorrect settings can damage the engine or cause other problems.

4.3. Analyzing Freeze Frame Data for Intermittent Issues

Freeze frame data is a snapshot of the engine’s operating conditions at the moment a diagnostic trouble code (DTC) is stored. This data can be invaluable for diagnosing intermittent issues that may not be present during a static test.

- Accessing Freeze Frame Data: VCDS allows you to access freeze frame data for any stored DTC. This data includes parameters such as:

- Engine speed (RPM)

- Engine load

- Coolant temperature

- Fuel trim values

- Ignition timing

- Interpreting Freeze Frame Data: By analyzing the freeze frame data, you can gain insights into the conditions that triggered the DTC. For example, if a misfire DTC is stored along with high engine load and low RPM, it may indicate a problem with the ignition coil’s ability to provide sufficient spark under those conditions.

5. Troubleshooting Common VCDS Issues During Ignition Coil Testing

While VCDS is a powerful tool, users may encounter issues during ignition coil testing. Here are some common problems and their solutions.

5.1. VCDS Not Connecting to the Vehicle

If VCDS is not connecting to the vehicle, there are several potential causes.

- Check the Cable Connection: Ensure that the VCDS interface cable is securely connected to both the vehicle’s OBD-II port and your laptop.

- Verify the Ignition is On: Make sure the vehicle’s ignition is turned on, but the engine is not running.

- Test the Cable: Test the VCDS interface cable on another vehicle to rule out a faulty cable.

- Check the Software Installation: Verify that the VCDS software is properly installed on your laptop. Reinstall the software if necessary.

- Update the Software: Make sure you are using the latest version of the VCDS software. Ross-Tech regularly releases updates that improve compatibility and fix bugs.

- Check the COM Port Settings: In the VCDS software, check the COM port settings to ensure they are correctly configured for your interface cable.

- Disable Other USB Devices: Disconnect any unnecessary USB devices from your laptop to avoid conflicts.

- Check for Driver Issues: Verify that the drivers for the VCDS interface cable are properly installed. Reinstall the drivers if necessary.

5.2. Inaccurate Misfire Readings

Inaccurate misfire readings can lead to misdiagnosis. Here’s how to address this issue:

- Verify Measuring Block Selection: Ensure that you have selected the correct measuring blocks for misfire counters in VCDS. Refer to the Ross-Tech Wiki or your vehicle’s service manual for the correct measuring block numbers.

- Check for Software Glitches: Restart the VCDS software and your laptop to clear any potential software glitches.

- Rule Out Other Causes: Misfires can be caused by factors other than ignition coils, such as faulty spark plugs, fuel injectors, or vacuum leaks. Perform additional tests to rule out these potential causes.

- Check for Electrical Interference: Electrical interference can sometimes cause inaccurate misfire readings. Try moving your laptop away from the vehicle’s engine compartment and other potential sources of interference.

5.3. Problems Performing Output Tests

If you encounter problems performing output tests on the ignition coils, consider these troubleshooting steps:

- Verify the Engine Module is Selected: Ensure that you have selected the correct engine control module (ECU) in VCDS before attempting to perform output tests.

- Check for DTCs: Diagnostic trouble codes (DTCs) can sometimes prevent output tests from running. Clear any stored DTCs and try running the output tests again.

- Check for Proper Voltage: Ensure that the vehicle’s battery has sufficient voltage to run the output tests. A low battery can sometimes prevent the tests from running properly.

- Consult the Ross-Tech Wiki: Refer to the Ross-Tech Wiki for specific instructions and troubleshooting tips for your vehicle model.

6. Optimizing Engine Performance After Ignition Coil Replacement

After replacing a faulty ignition coil, it’s essential to optimize engine performance to ensure smooth operation and prevent future issues. Here are several steps you can take:

6.1. Clearing Fault Codes and Resetting the ECU

After replacing the ignition coil, clear all stored fault codes using VCDS. This ensures that the engine control unit (ECU) recognizes the new coil and adjusts accordingly. Clearing the codes also helps to identify any new issues that may arise.

To reset the ECU, disconnect the negative battery terminal for about 15-20 minutes. This allows the ECU to reset its learned parameters and relearn the optimal settings for the new ignition coil.

6.2. Performing a Throttle Body Adaptation

A throttle body adaptation is necessary, especially if the vehicle exhibited rough idling or stalling issues before the ignition coil replacement. The throttle body adaptation process allows the ECU to relearn the idle position and ensure smooth engine operation.

Using VCDS, navigate to the engine control module, select “Basic Settings,” and choose the throttle body adaptation function. Follow the on-screen instructions to complete the adaptation process. This will help optimize the air-fuel mixture and improve idle stability.

6.3. Monitoring Engine Performance with VCDS

After the ignition coil replacement and adaptation, use VCDS to monitor engine performance. Pay close attention to the following parameters:

- Misfire Counts: Monitor the misfire counts for each cylinder to ensure that the replaced ignition coil is functioning correctly and no new misfires are occurring.

- Fuel Trims: Check the short-term and long-term fuel trim values to ensure that the air-fuel mixture is within the optimal range. Adjustments may be necessary if the fuel trims are significantly outside the acceptable range.

- O2 Sensor Readings: Monitor the oxygen sensor readings to ensure proper combustion and emissions control. Abnormal O2 sensor readings may indicate underlying issues that need to be addressed.

- Engine Speed (RPM): Monitor the engine speed at idle and during acceleration to ensure smooth and stable operation. Adjustments to the idle speed may be necessary to achieve optimal performance.

6.4. Checking and Replacing Spark Plugs

When replacing ignition coils, it’s a good practice to inspect the spark plugs. Worn or fouled spark plugs can cause ignition coils to work harder, leading to premature failure. Replace the spark plugs if they show signs of wear, such as:

- Worn Electrodes: If the electrodes are rounded or excessively worn, replace the spark plugs.

- Fouling: If the spark plugs are covered in carbon deposits, oil, or fuel, clean or replace them.

- Cracks or Damage: Inspect the spark plugs for any cracks or physical damage, and replace them if necessary.

Replacing the spark plugs ensures optimal combustion and reduces the strain on the new ignition coil.

6.5. Inspecting and Cleaning Fuel Injectors

Fuel injectors play a crucial role in delivering the correct amount of fuel to each cylinder. Dirty or clogged fuel injectors can cause misfires and affect engine performance. Consider inspecting and cleaning the fuel injectors, especially if the vehicle has high mileage or exhibits symptoms of fuel delivery issues.

You can use fuel injector cleaners or have the injectors professionally cleaned. Ensure that the fuel injectors are functioning correctly to optimize engine performance and prevent future ignition coil failures.

Alt Text: Close-up of worn-out spark plugs showing signs of wear and carbon deposits, highlighting the importance of regular spark plug replacement to maintain optimal engine performance.

7. Preventive Maintenance Tips for Ignition Coils

Preventive maintenance is crucial for extending the lifespan of ignition coils and avoiding costly repairs. Here are some essential tips:

7.1. Regular Spark Plug Replacement

As mentioned earlier, worn or faulty spark plugs can significantly impact ignition coil performance. Follow the manufacturer’s recommended service intervals for spark plug replacement. This helps maintain optimal combustion and reduces the strain on the ignition coils.

7.2. Keep the Engine Clean

A clean engine runs cooler, which helps prevent overheating and extends the lifespan of ignition coils. Regularly clean the engine bay to remove dirt, debris, and oil buildup. This improves airflow and reduces the risk of heat-related damage to the ignition coils.

7.3. Avoid Engine Misfires

Engine misfires can cause excessive stress on the ignition coils, leading to premature failure. Address any issues that cause misfires promptly, such as:

- Fuel Delivery Problems: Ensure that the fuel system is functioning correctly and that the fuel injectors are clean.

- Vacuum Leaks: Check for vacuum leaks, as they can cause lean air-fuel mixtures and misfires.

- Compression Issues: Address any compression problems, as they can prevent proper combustion.

7.4. Use High-Quality Fuel

Using high-quality fuel helps maintain optimal engine performance and prevents the buildup of deposits that can affect ignition coil operation. Avoid using low-quality fuel, as it may contain additives that can damage the fuel system and ignition components.

7.5. Regularly Inspect and Maintain the Ignition System

Regularly inspect the ignition system components, including the wiring, connectors, and coils. Look for signs of wear, damage, or corrosion. Replace any faulty components promptly to prevent further damage to the ignition coils.

8. Understanding Ignition Coil Testing in Different Vehicle Models

Ignition coil testing can vary depending on the vehicle model and the type of ignition system. Here’s an overview of how ignition coil testing can differ in various vehicles:

8.1. Testing in Modern Vehicles with Coil-on-Plug (COP) Systems

Modern vehicles often use coil-on-plug (COP) systems, where each cylinder has its ignition coil directly attached to the spark plug. This design eliminates the need for spark plug wires and provides a more efficient and reliable ignition system.

- Individual Coil Testing: VCDS allows you to test each COP coil individually, making it easier to identify faulty coils.

- Misfire Detection: COP systems typically have more precise misfire detection capabilities, allowing for more accurate diagnostics.

- Output Tests: VCDS output tests can be used to activate each COP coil and verify its functionality.

8.2. Testing in Older Vehicles with Distributor-Based Systems

Older vehicles may use distributor-based ignition systems, where a single ignition coil provides spark to all cylinders via a distributor and spark plug wires. Testing ignition coils in these systems involves different techniques:

- Primary and Secondary Resistance Testing: Use a multimeter to measure the primary and secondary resistance of the ignition coil. Compare the readings to the manufacturer’s specifications to determine if the coil is faulty.

- Spark Test: Perform a spark test to check if the ignition coil is producing a strong spark. Disconnect the spark plug wire from the spark plug, insert a test spark plug into the wire, and ground the test spark plug. Crank the engine and observe the spark. A weak or non-existent spark indicates a faulty ignition coil.

- Voltage Testing: Use a voltmeter to measure the voltage at the ignition coil terminals. Ensure that the coil is receiving the correct voltage from the battery and the ignition switch.

8.3. Testing in High-Performance Vehicles

High-performance vehicles often have enhanced ignition systems to provide more power and efficiency. Testing ignition coils in these vehicles may require specialized tools and techniques:

- Oscilloscope Testing: Use an oscilloscope to analyze the ignition coil’s waveform. This can provide detailed information about the coil’s performance, such as its dwell time, voltage output, and firing pattern.

- Data Logging: Use VCDS or other diagnostic tools to log data about the ignition system’s performance under various driving conditions. This can help identify issues that may not be apparent during static testing.

- Performance Upgrades: Consider upgrading the ignition coils to high-performance aftermarket coils to improve engine performance and reliability.

9. Benefits of Purchasing Diagnostic Tools from CARDIAGTECH.NET

Investing in quality diagnostic tools is essential for accurate and efficient ignition coil testing. CARDIAGTECH.NET offers a wide range of VCDS tools and other diagnostic equipment to meet your needs. Here are some of the benefits of purchasing from CARDIAGTECH.NET:

9.1. Wide Selection of High-Quality Diagnostic Tools

CARDIAGTECH.NET offers a comprehensive selection of diagnostic tools, including VCDS interfaces, multimeters, oscilloscopes, and more. Our tools are sourced from reputable manufacturers and are designed to provide accurate and reliable results.

9.2. Expert Technical Support and Guidance

Our team of experienced technicians is available to provide expert technical support and guidance. We can help you choose the right tools for your needs and provide assistance with troubleshooting and diagnostics.

9.3. Competitive Pricing and Fast Shipping

CARDIAGTECH.NET offers competitive pricing on all our diagnostic tools. We also provide fast shipping to ensure that you receive your tools quickly and can start testing ignition coils right away.

9.4. Warranty and Satisfaction Guarantee

We stand behind the quality of our products and offer a warranty on all diagnostic tools. If you are not satisfied with your purchase, you can return it for a full refund.

By purchasing diagnostic tools from CARDIAGTECH.NET, you can ensure that you have the equipment you need to accurately and efficiently test ignition coils and maintain optimal engine performance.

Ready to enhance your diagnostic capabilities? Contact CARDIAGTECH.NET today for expert advice and top-quality diagnostic tools. Reach out via Whatsapp at +1 (641) 206-8880 or visit our website at CARDIAGTECH.NET. Our address is 276 Reock St, City of Orange, NJ 07050, United States. Let us help you achieve peak performance in your automotive repairs.

Alt Text: A selection of diagnostic tools available at CARDIAGTECH.NET, showcasing various devices like VCDS interfaces, multimeters, and oscilloscopes used for automotive diagnostics.

10. Frequently Asked Questions (FAQs) About VCDS Ignition Coil Testing

Q1: What is VCDS and what is it used for?

VCDS (VAG-COM Diagnostic System) is a diagnostic tool used primarily for Volkswagen, Audi, SEAT, and Škoda vehicles. It allows users to access, diagnose, and program various electronic control units (ECUs) within these vehicles, offering in-depth insights and control beyond generic OBD-II scanners.

Q2: How do I connect VCDS to my vehicle?

To connect VCDS to your vehicle, you need a VCDS interface cable and a laptop with the VCDS software installed. Plug the interface cable into the OBD-II port of your vehicle and connect the other end to a USB port on your laptop. Turn on the ignition and launch the VCDS software.

Q3: What are the common symptoms of a failing ignition coil?

Common symptoms of a failing ignition coil include engine misfires, rough idling, decreased fuel efficiency, a check engine light, loss of power, engine stalling, and difficulty starting the engine.

Q4: How can VCDS help in diagnosing ignition coil issues?

VCDS can help diagnose ignition coil issues by reading diagnostic trouble codes (DTCs), monitoring live data for misfires, performing output tests on ignition coils, and analyzing freeze frame data for intermittent issues.

Q5: What diagnostic trouble codes (DTCs) are related to ignition coil problems?

Common DTCs related to ignition coil problems include P0300 (Random/Multiple Cylinder Misfire Detected), P0301-P0312 (Cylinder X Misfire Detected), and P0351-P0360 (Ignition Coil A-J Primary/Secondary Circuit Malfunction).

Q6: Can VCDS perform output tests on ignition coils?

Yes, VCDS can perform output tests on ignition coils. This feature allows you to cycle each ignition coil on and off, helping you verify their functionality and identify any potential problems.

Q7: What should I do after replacing a faulty ignition coil?

After replacing a faulty ignition coil, clear all stored fault codes using VCDS, perform a throttle body adaptation (if necessary), and monitor engine performance to ensure smooth operation.

Q8: How often should I replace my spark plugs?

You should replace your spark plugs according to the manufacturer’s recommended service intervals, typically every 30,000 to 100,000 miles.

Q9: Where can I purchase high-quality VCDS tools?

You can purchase high-quality VCDS tools from CARDIAGTECH.NET. We offer a wide selection of diagnostic tools, expert technical support, competitive pricing, and a satisfaction guarantee.

Q10: How can I contact CARDIAGTECH.NET for assistance?

You can contact CARDIAGTECH.NET for assistance via Whatsapp at +1 (641) 206-8880 or visit our website at CARDIAGTECH.NET. Our address is 276 Reock St, City of Orange, NJ 07050, United States.

By understanding these FAQs, you can better utilize VCDS for ignition coil testing and maintain optimal engine performance.