Vcds Cannot Connect To Controller? CARDIAGTECH.NET understands the frustration when your VCDS tool fails to connect, hindering your diagnostic and repair efforts. This comprehensive guide dives into the reasons behind this issue and offers practical solutions to get you back on track, ensuring seamless automotive diagnostics with your VCDS setup, alongside exploring various VCDS alternatives.

1. Understanding “VCDS Cannot Connect to Controller”

The error “VCDS cannot connect to controller” is a common headache for automotive technicians using the VCDS (VAG-COM Diagnostic System) tool. This issue prevents communication between the VCDS interface and the vehicle’s control modules, making diagnostics and adaptations impossible. Understanding the root causes of this error is the first step toward resolving it.

1.1. What is VCDS?

VCDS, developed by Ross-Tech, is a software and hardware package used for diagnosing and modifying settings in Volkswagen, Audi, Skoda, and SEAT vehicles. It allows users to access various control modules within the car, read fault codes, view live data, perform output tests, and program certain functions.

1.2. Common Symptoms

When VCDS fails to connect, you might encounter these symptoms:

- “No Response from Controller” Error: This is the most common message, indicating that the VCDS software cannot establish communication with the selected control module.

- “KLine Init Failed” Error: This error suggests a problem with the K-line communication, often due to an issue with the interface or the vehicle’s wiring.

- Autoscan Failure: The VCDS tool fails to detect and communicate with any or all of the vehicle’s control modules during an autoscan.

- Interface LED Issues: The LED on the VCDS interface may blink erratically, remain off, or display an error color, indicating a connection problem.

1.3. Potential Causes

Several factors can contribute to the “VCDS cannot connect to controller” error:

- Faulty Interface: The VCDS interface cable itself may be damaged or malfunctioning.

- Software Problems: Issues with the VCDS software installation, drivers, or configuration can cause connection failures.

- Vehicle Issues: Problems with the vehicle’s OBD-II port, wiring, or control modules can prevent communication.

- Aftermarket Devices: Aftermarket radios, alarms, or other electronic devices can interfere with the VCDS communication.

- Incorrect Settings: Incorrect VCDS settings, such as the wrong communication port or protocol, can lead to connection errors.

VCDS Interface Cable

VCDS Interface Cable

Alt: VCDS interface cable connected to a laptop, used for diagnosing Volkswagen and Audi vehicles.

2. Preliminary Checks

Before diving into advanced troubleshooting, perform these basic checks to rule out simple issues:

2.1. Check the Connection

- OBD-II Port: Ensure the VCDS interface cable is securely plugged into the vehicle’s OBD-II port. Check for any damage or debris in the port.

- Cable Integrity: Inspect the cable for any visible damage, such as cuts, frayed wires, or bent connectors.

- USB Connection: Make sure the USB cable is properly connected to your computer. Try a different USB port to rule out a faulty port.

2.2. Verify the Ignition

- Ignition On: VCDS typically requires the vehicle’s ignition to be switched on to establish communication. Ensure the key is in the “ON” position, but the engine does not need to be running.

- Battery Voltage: A low battery voltage can sometimes interfere with VCDS communication. Verify that the battery voltage is above 12V.

2.3. Software and Drivers

- VCDS Software Version: Ensure you are using the latest version of the VCDS software. Older versions may have compatibility issues or bugs that cause connection problems.

- Driver Installation: Verify that the VCDS interface drivers are properly installed on your computer. Reinstall the drivers if necessary.

- Software Compatibility: Confirm that the VCDS software is compatible with your computer’s operating system.

3. Troubleshooting Steps

If the preliminary checks don’t resolve the issue, proceed with these troubleshooting steps:

3.1. Test the Interface

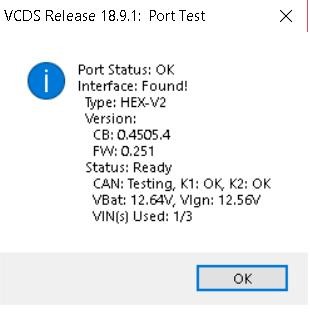

- VCDS Interface Test: Use the VCDS software to test the interface. Go to “Options” and click “Test.” This will check the interface’s communication with the software.

- LED Indicators: Observe the LED indicators on the interface during the test. Refer to the VCDS manual to interpret the LED patterns and identify any potential issues.

3.2. Check the Vehicle’s Wiring

- OBD-II Port Wiring: Inspect the wiring of the OBD-II port for any loose, damaged, or corroded wires. Refer to the vehicle’s wiring diagram to identify the correct pin assignments.

- Ground Connections: Check the vehicle’s ground connections, as poor grounding can interfere with VCDS communication. Ensure the ground straps are clean and securely connected.

3.3. Rule Out Aftermarket Devices

- Disconnect Aftermarket Devices: Disconnect any aftermarket radios, alarms, or other electronic devices that may be interfering with the VCDS communication.

- Test with OEM Radio: If you have an aftermarket radio installed, try reinstalling the original OEM radio to see if it resolves the connection issue.

3.4. Advanced Diagnostics

- Check K-Line Voltage: Use a multimeter to check the voltage on the K-line (typically pin 7) of the OBD-II port. The voltage should be around 12V.

- Scan Tool Compatibility: Try using a different scan tool to see if it can communicate with the vehicle’s control modules. If another scan tool works, the issue may be specific to the VCDS interface or software.

3.5. Contact Support

- Ross-Tech Support: If you’ve exhausted all troubleshooting steps, contact Ross-Tech support for assistance. They may be able to provide specific guidance based on your VCDS interface and vehicle.

4. Step-by-Step Solutions

Let’s explore some step-by-step solutions for common “VCDS cannot connect to controller” scenarios:

4.1. Solution 1: Reinstall VCDS Software and Drivers

- Uninstall VCDS: Completely uninstall the VCDS software from your computer.

- Remove Drivers: Manually remove the VCDS interface drivers from the Device Manager.

- Download Latest Version: Download the latest version of the VCDS software from the Ross-Tech website.

- Install VCDS: Install the VCDS software, following the on-screen instructions.

- Install Drivers: Install the VCDS interface drivers when prompted.

- Test Connection: Connect the VCDS interface to your computer and vehicle, and test the connection using the VCDS software.

4.2. Solution 2: Check and Repair OBD-II Port Wiring

- Locate OBD-II Port: Find the OBD-II port in your vehicle (usually located under the dashboard).

- Inspect Wiring: Visually inspect the wiring connected to the OBD-II port for any damage, loose connections, or corrosion.

- Repair Wiring: Repair or replace any damaged wires or connectors. Ensure all connections are secure and properly insulated.

- Test Connection: Connect the VCDS interface to the OBD-II port and test the connection using the VCDS software.

4.3. Solution 3: Disable or Remove Aftermarket Devices

- Identify Aftermarket Devices: Identify any aftermarket radios, alarms, or other electronic devices installed in your vehicle.

- Disconnect Devices: Disconnect these devices one by one, and test the VCDS connection after each disconnection.

- Isolate Interference: If disconnecting a specific device resolves the connection issue, that device is likely interfering with the VCDS communication.

- Remove or Replace: Remove the interfering device or replace it with a compatible alternative.

4.4. Solution 4: Adjust VCDS Settings

- Open VCDS Options: Open the VCDS software and go to “Options.”

- Select COM Port: Ensure the correct COM port is selected for your VCDS interface.

- Adjust Latency Timer: Try adjusting the latency timer setting. A lower latency timer may improve communication reliability.

- Test Connection: Save the changes and test the connection using the VCDS software.

5. VCDS Alternatives

While VCDS is a popular choice for VW/Audi diagnostics, several alternatives offer similar functionality:

| Alternative | Description | Pros | Cons | Price |

|---|---|---|---|---|

| OBDeleven | Cloud-based diagnostic tool for VW/Audi group vehicles. | User-friendly interface, mobile app, one-click apps. | Requires internet connection, limited functionality without credits. | $70 – $200+ |

| Autel MaxiCOM | Professional-grade diagnostic tool with extensive vehicle coverage. | Wide vehicle coverage, advanced functions, bi-directional control. | High cost, complex interface. | $1,000 – $5,000+ |

| Launch X431 | Comprehensive diagnostic tool with wide vehicle coverage and advanced features. | Wide vehicle coverage, advanced functions, remote diagnostics. | High cost, complex interface, subscription fees. | $800 – $3,000+ |

| CARDIAGTECH.NET Tools | Specialized diagnostic and programming tools tailored for various vehicle makes and models. | User-friendly interface, comprehensive diagnostics, advanced programming capabilities, excellent customer support, competitive pricing. | May require additional adapters for certain vehicle models, ongoing software updates to maintain compatibility. | $100 – $2,000+ |

| Thinktool | Modular diagnostic tool with various add-on modules for extended functionality. | Modular design, wide vehicle coverage, advanced functions. | Can be expensive with multiple modules, complex interface. | $500 – $2,000+ |

CARDIAGTECH.NET offers a range of diagnostic tools that can serve as excellent alternatives, providing comprehensive diagnostics, user-friendly interfaces, and competitive pricing.

6. Maintaining Your VCDS Setup

To prevent future connection issues, follow these maintenance tips:

- Keep Software Updated: Regularly update your VCDS software to the latest version.

- Protect the Interface: Store the VCDS interface in a safe place to prevent damage.

- Check Cables Regularly: Inspect the cables for any signs of wear and tear.

- Avoid Extreme Temperatures: Avoid using VCDS in extreme temperatures, as this can affect the interface’s performance.

7. The Importance of Reliable Diagnostic Tools

Reliable diagnostic tools are essential for efficient and accurate automotive repairs. They enable technicians to quickly identify and resolve issues, saving time and money. Investing in high-quality tools like VCDS or CARDIAGTECH.NET diagnostic solutions is a smart move for any automotive professional.

7.1. Benefits of Using VCDS

- Accurate Diagnostics: VCDS provides accurate diagnostic information, helping technicians pinpoint the root cause of vehicle problems.

- Efficient Repairs: By quickly identifying issues, VCDS helps technicians perform repairs more efficiently.

- Cost Savings: Accurate diagnostics and efficient repairs can save time and money for both technicians and vehicle owners.

- Enhanced Customer Satisfaction: Providing accurate and timely repairs can enhance customer satisfaction and build trust.

7.2. Benefits of Using CARDIAGTECH.NET Tools

- Comprehensive Diagnostics: CARDIAGTECH.NET tools offer comprehensive diagnostic capabilities, covering a wide range of vehicle systems and components.

- User-Friendly Interface: With intuitive interfaces, CARDIAGTECH.NET tools are easy to use, even for novice technicians.

- Advanced Programming: CARDIAGTECH.NET tools offer advanced programming capabilities, allowing technicians to perform complex adaptations and calibrations.

- Excellent Support: CARDIAGTECH.NET provides excellent customer support, ensuring technicians have the assistance they need to resolve any issues.

8. Real-World Scenarios

Let’s look at some real-world scenarios where the “VCDS cannot connect to controller” error might occur and how to resolve them:

8.1. Scenario 1: Aftermarket Radio Interference

Problem: A technician installs an aftermarket radio in a VW Golf and then finds that VCDS cannot connect to any of the vehicle’s control modules.

Solution:

- Disconnect the aftermarket radio.

- Test the VCDS connection.

- If the connection is restored, the aftermarket radio is likely the cause of the interference.

- Either remove the aftermarket radio or install a noise filter to prevent interference.

8.2. Scenario 2: Damaged OBD-II Port Wiring

Problem: A technician attempts to use VCDS on an Audi A4 but gets a “No Response from Controller” error. Upon inspection, they find that the OBD-II port wiring is damaged.

Solution:

- Repair or replace the damaged OBD-II port wiring.

- Ensure all connections are secure and properly insulated.

- Test the VCDS connection.

8.3. Scenario 3: Software Compatibility Issues

Problem: A technician upgrades their computer’s operating system and then finds that VCDS can no longer connect to any vehicles.

Solution:

- Check the VCDS software’s compatibility with the new operating system.

- Download and install the latest version of VCDS that is compatible with the operating system.

- Reinstall the VCDS interface drivers.

- Test the connection.

9. Expert Insights and Recommendations

According to automotive diagnostic experts, “The ‘VCDS cannot connect to controller’ error is often a result of simple issues such as loose connections or outdated software. Always start with the basic checks and then move on to more advanced troubleshooting.”

Ross-Tech, the developer of VCDS, recommends, “Ensure that your VCDS software and interface drivers are always up to date. Also, be aware of potential interference from aftermarket devices.”

CARDIAGTECH.NET experts add, “When troubleshooting connection issues, consider the possibility of faulty vehicle wiring or control modules. A thorough inspection can often reveal the root cause of the problem.”

10. Call to Action

Experiencing the frustration of “VCDS cannot connect to controller”? Don’t let diagnostic roadblocks slow you down. At CARDIAGTECH.NET, we offer a range of advanced diagnostic tools designed to get you back on track quickly and efficiently.

Ready to enhance your diagnostic capabilities?

- Contact us today for a personalized consultation: Whatsapp: +1 (641) 206-8880

- Explore our wide selection of diagnostic tools: Visit CARDIAGTECH.NET

- Visit our store: 276 Reock St, City of Orange, NJ 07050, United States

Let CARDIAGTECH.NET be your trusted partner in automotive diagnostics. Contact us now and discover how our innovative solutions can transform your repair process!

11. Optimizing Your Workshop with CARDIAGTECH.NET Tools

Investing in the right diagnostic tools can significantly optimize your workshop’s efficiency and profitability. CARDIAGTECH.NET offers a range of solutions designed to meet the diverse needs of modern automotive repair facilities.

11.1. Streamlining Diagnostic Processes

With CARDIAGTECH.NET tools, you can streamline your diagnostic processes, reducing the time it takes to identify and resolve vehicle issues. Our intuitive interfaces and advanced features enable technicians to quickly access critical information, perform accurate diagnostics, and implement effective repairs.

11.2. Enhancing Repair Accuracy

CARDIAGTECH.NET tools provide precise and reliable diagnostic data, helping technicians avoid costly errors and ensure the accuracy of their repairs. By investing in our high-quality solutions, you can minimize comebacks and enhance customer satisfaction.

11.3. Increasing Workshop Profitability

By optimizing your diagnostic processes and enhancing repair accuracy, CARDIAGTECH.NET tools can help increase your workshop’s profitability. Our solutions enable you to complete more jobs in less time, reduce waste, and improve overall efficiency.

11.4. Staying Ahead of the Curve

The automotive industry is constantly evolving, with new technologies and systems being introduced on a regular basis. CARDIAGTECH.NET tools are designed to keep you ahead of the curve, providing comprehensive coverage of the latest vehicle makes and models.

12. The Future of Automotive Diagnostics

The future of automotive diagnostics is rapidly evolving, with new technologies and techniques emerging all the time. As vehicles become more complex, the need for advanced diagnostic tools and skilled technicians will only continue to grow.

12.1. AI-Powered Diagnostics

Artificial intelligence (AI) is poised to revolutionize the automotive diagnostic industry, enabling technicians to quickly and accurately identify complex issues. AI-powered diagnostic tools can analyze vast amounts of data, identify patterns, and provide insights that would be impossible for humans to detect.

12.2. Remote Diagnostics

Remote diagnostics is another emerging trend that is transforming the way automotive repairs are performed. With remote diagnostic tools, technicians can diagnose and repair vehicles from anywhere in the world, reducing downtime and improving customer satisfaction.

12.3. Augmented Reality

Augmented reality (AR) is also poised to play a significant role in the future of automotive diagnostics. AR-enabled diagnostic tools can overlay digital information onto the real world, providing technicians with step-by-step instructions and guidance.

13. Investing in Your Team

Investing in your team’s training and development is essential for ensuring the long-term success of your workshop. By providing your technicians with the knowledge and skills they need to use advanced diagnostic tools effectively, you can improve their performance, enhance their job satisfaction, and reduce employee turnover.

13.1. Training Programs

CARDIAGTECH.NET offers a range of training programs designed to help your technicians master the use of our diagnostic tools. Our training programs cover a wide range of topics, including basic diagnostics, advanced programming, and troubleshooting techniques.

13.2. Certification Programs

We also offer certification programs that recognize technicians who have demonstrated a high level of proficiency in the use of our diagnostic tools. Certification can enhance your technicians’ credibility and help them stand out from the competition.

13.3. Continuous Learning

The automotive industry is constantly evolving, so it’s important to encourage your technicians to engage in continuous learning. By providing them with access to online resources, industry events, and professional development opportunities, you can help them stay up-to-date on the latest trends and technologies.

14. Maximizing the Value of Your Diagnostic Tools

To maximize the value of your diagnostic tools, it’s important to use them effectively and maintain them properly. Here are some tips for getting the most out of your investment:

14.1. Read the Manual

Before using any diagnostic tool, take the time to read the manual carefully. The manual contains important information about the tool’s features, functions, and limitations.

14.2. Keep the Tool Clean

Keep your diagnostic tools clean and free of dirt, dust, and debris. Use a soft cloth to wipe down the tool after each use.

14.3. Store the Tool Properly

Store your diagnostic tools in a safe and dry place. Avoid exposing the tool to extreme temperatures or humidity.

14.4. Update the Software Regularly

Keep the software on your diagnostic tools up-to-date. Software updates often include bug fixes, new features, and improved performance.

15. FAQs About “VCDS Cannot Connect to Controller”

Here are some frequently asked questions about the “VCDS cannot connect to controller” error:

- What does “VCDS cannot connect to controller” mean? This error indicates that the VCDS software is unable to establish communication with the vehicle’s control modules.

- What are the common causes of this error? Common causes include faulty interface, software problems, vehicle issues, aftermarket devices, and incorrect settings.

- How can I troubleshoot this error? Start by checking the connection, verifying the ignition, and checking the software and drivers. Then, proceed with advanced troubleshooting steps such as testing the interface and checking the vehicle’s wiring.

- Can aftermarket devices cause this error? Yes, aftermarket radios, alarms, and other electronic devices can interfere with VCDS communication.

- What are some VCDS alternatives? Alternatives include OBDeleven, Autel MaxiCOM, Launch X431, and CARDIAGTECH.NET tools.

- How can I prevent this error from occurring? Keep your VCDS software updated, protect the interface, check cables regularly, and avoid extreme temperatures.

- Is it necessary to contact support for this error? If you’ve exhausted all troubleshooting steps, contacting Ross-Tech support may be necessary.

- Can a low battery voltage cause this error? Yes, a low battery voltage can sometimes interfere with VCDS communication.

- How do I check the K-line voltage? Use a multimeter to check the voltage on the K-line (typically pin 7) of the OBD-II port.

- Where can I find the latest version of the VCDS software? You can download the latest version of the VCDS software from the Ross-Tech website.

By understanding the causes and solutions for the “VCDS cannot connect to controller” error, you can minimize downtime and keep your diagnostic efforts on track. And remember, CARDIAGTECH.NET is here to support you with top-quality diagnostic tools and expert assistance.