This article addresses troubleshooting camshaft timing issues on a 1.8T engine, specifically using VCDS to interpret Measuring Blocks 91 and 93. We will explore a real-world scenario of a car owner experiencing timing problems after an engine swap and attempting to diagnose the issue using VCDS.

Understanding VCDS and Camshaft Timing

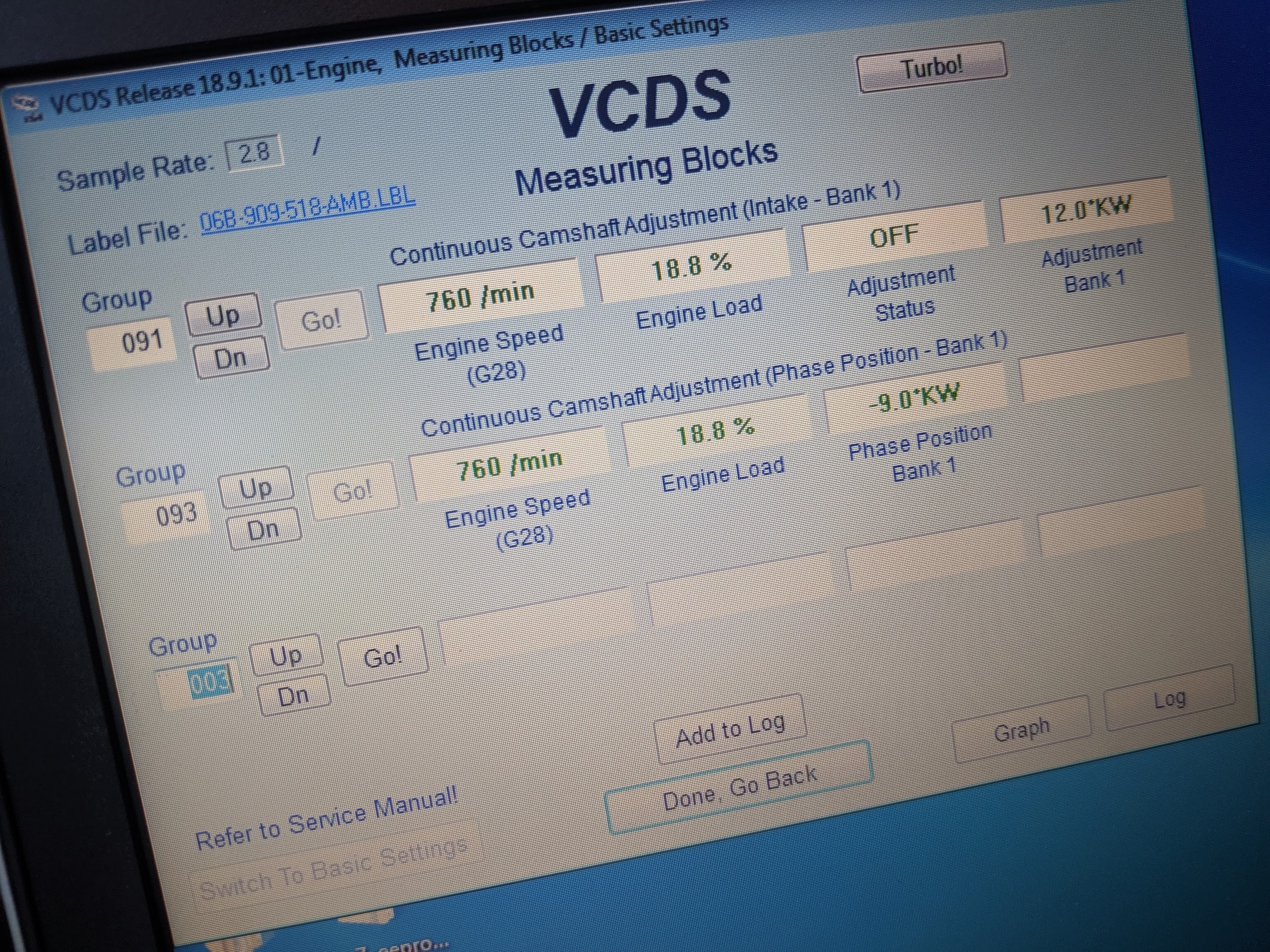

VCDS (Vag-Com Diagnostic System) is a powerful diagnostic tool used for Volkswagen, Audi, Seat, and Skoda vehicles. It allows users to access and interpret various engine parameters, including camshaft timing. Measuring Block 93 (Phase Position Bank 1) indicates the actual camshaft timing, while Measuring Block 91 (Adjustment Bank 1) shows the ECU’s attempts to adjust the timing. Ideally, Measuring Block 93 should be close to 0 degrees KW, with a tolerance of +/- 6 degrees.

Case Study: 1.8T Engine Swap and Timing Issues

A car owner replaced a 1.8T engine (likely an AMB engine) with an AWP engine. While these engines share many similarities, subtle differences can lead to timing issues. After the swap, a VCDS scan revealed a -11 degrees KW reading in Measuring Block 93, indicating significantly retarded camshaft timing.

The owner replaced the timing chain and tensioner, ensuring 16 rollers between the gear marks. However, aligning the camshaft cap marks with the cam gear marks proved challenging. Despite the correct roller count, achieving perfect alignment on both camshafts seemed impossible. After starting the engine, the reading in Measuring Block 93 improved slightly to -9 degrees KW, but remained outside the acceptable range.

Suspecting the timing belt, the owner attempted to adjust the camshaft timing by slightly rotating the cam gear. However, this resulted in Measuring Block 91 changing from 0 to +12 degrees, further complicating the issue.

Analyzing the Problem and Potential Solutions

The core issue lies in the persistent deviation in Measuring Block 93 from the ideal 0 degrees KW. The unsuccessful attempt to adjust the timing via the cam gear, reflected in the change in Measuring Block 91, suggests a more fundamental problem.

Possible causes include:

- Incorrect Cam Gear Installation: Despite counting 16 rollers, the cam gears might be one tooth off. Double-checking the alignment marks on both camshafts and the crankshaft is crucial.

- Variations Between AWP and AMB Engines: Although assumed similar, minor differences in camshaft or crankshaft sensors between the AWP and AMB engines could affect the readings. Consulting engine-specific documentation is recommended.

- Timing Chain Tensioner: While replaced, the new tensioner might require some time to fully pressurize and properly tension the chain. Allowing the engine to run for a longer period might resolve this.

- Camshaft Position Sensor Issue: A faulty camshaft position sensor could provide inaccurate readings to the ECU, leading to incorrect timing adjustments. Testing the sensor is advisable.

Conclusion

Using VCDS to perform a camshaft adjustment test is essential for diagnosing timing issues on 1.8T engines. In this case, the persistent negative reading in Measuring Block 93, even after replacing the timing chain and tensioner, indicates a more complex problem. Thoroughly checking cam gear alignment, considering potential differences between AWP and AMB engines, and inspecting the camshaft position sensor are crucial steps in resolving the issue. Accurate diagnosis and proper timing are vital for optimal engine performance and longevity.