Vcds Cam Timing: Achieving Precision with Diagnostic Tools

Are you struggling with VCDS cam timing adjustments and seeking optimal engine performance? CARDIAGTECH.NET understands the complexities involved in precise cam timing, and we’re here to provide solutions. By using the right diagnostic equipment and following best practices, you can achieve accurate adjustments. Find out how to streamline your workflow with timing verification, camshaft adjustment, and diagnostic precision.

1. Understanding VCDS Cam Timing Fundamentals

To fully grasp VCDS cam timing, it’s essential to understand its core principles. Cam timing directly influences engine performance by controlling when intake and exhaust valves open and close. Precise timing ensures optimal combustion, maximizing power, efficiency, and reducing emissions.

1.1. Defining Cam Timing

Cam timing is the synchronization of the camshaft’s rotation with the crankshaft’s position. This synchronization dictates when the engine’s valves open and close during the intake, compression, combustion, and exhaust strokes. Precise cam timing ensures the engine operates efficiently, delivering optimal power and fuel economy.

1.2. The Role of VCDS in Cam Timing

VCDS (Vag-Com Diagnostic System) is a diagnostic tool used extensively for Volkswagen Audi Group (VAG) vehicles. It allows technicians to read and interpret data from the engine control unit (ECU), including cam timing measurements. VCDS helps diagnose issues by showing deviations from specified values and allows for adjustments to be made and monitored in real-time.

1.3. Common Symptoms of Incorrect Cam Timing

Incorrect cam timing can manifest in a variety of noticeable symptoms that affect engine performance:

- Reduced Power: The engine may feel sluggish and less responsive.

- Poor Fuel Economy: Inefficient combustion leads to increased fuel consumption.

- Rough Idle: The engine may vibrate or idle erratically.

- Check Engine Light: The ECU detects timing discrepancies and triggers a warning.

- Increased Emissions: Incomplete combustion results in higher levels of pollutants.

1.4. Essential Tools for Cam Timing Adjustment

Having the right tools is crucial for accurate cam timing adjustments. Here’s a list of essential tools:

- VCDS Diagnostic Tool: For reading and interpreting ECU data.

- Camshaft Locking Tools: To hold the camshafts in the correct position.

- Crankshaft Locking Tool: To ensure the crankshaft is at Top Dead Center (TDC).

- Torque Wrench: For tightening bolts to specified torque values.

- Timing Belt/Chain Tools: For removing and installing the timing belt or chain.

2. Step-by-Step Guide to Checking Cam Timing with VCDS

Checking cam timing with VCDS involves a systematic approach to ensure accuracy. This section provides a detailed, step-by-step guide to help you through the process.

2.1. Preparing for the Inspection

Before diving into the VCDS procedure, proper preparation is vital. This includes gathering necessary information and ensuring the vehicle is ready for inspection.

- Gather Information: Collect the vehicle’s year, make, and engine code.

- Consult Repair Manuals: Review the repair manual for specific cam timing specifications.

- Warm-Up Engine: Ensure the engine is at normal operating temperature.

- Park Safely: Park the vehicle on a level surface and engage the parking brake.

2.2. Connecting VCDS to the Vehicle

Connecting VCDS to the vehicle correctly ensures seamless communication with the ECU. Follow these steps:

- Locate the OBD-II Port: Usually found under the dashboard on the driver’s side.

- Plug in VCDS Cable: Connect the VCDS cable to the OBD-II port.

- Turn on Ignition: Turn the ignition to the “ON” position without starting the engine.

- Launch VCDS Software: Open the VCDS software on your computer.

2.3. Accessing Engine Control Module (ECU)

Navigating to the Engine Control Module (ECU) is crucial for accessing cam timing data. Here’s how to do it:

- Select Control Module: In VCDS, select “Select Control Module.”

- Choose Engine: Choose the “01-Engine” option.

- Wait for Connection: Allow VCDS to establish a connection with the ECU.

2.4. Reading Measuring Blocks for Cam Timing

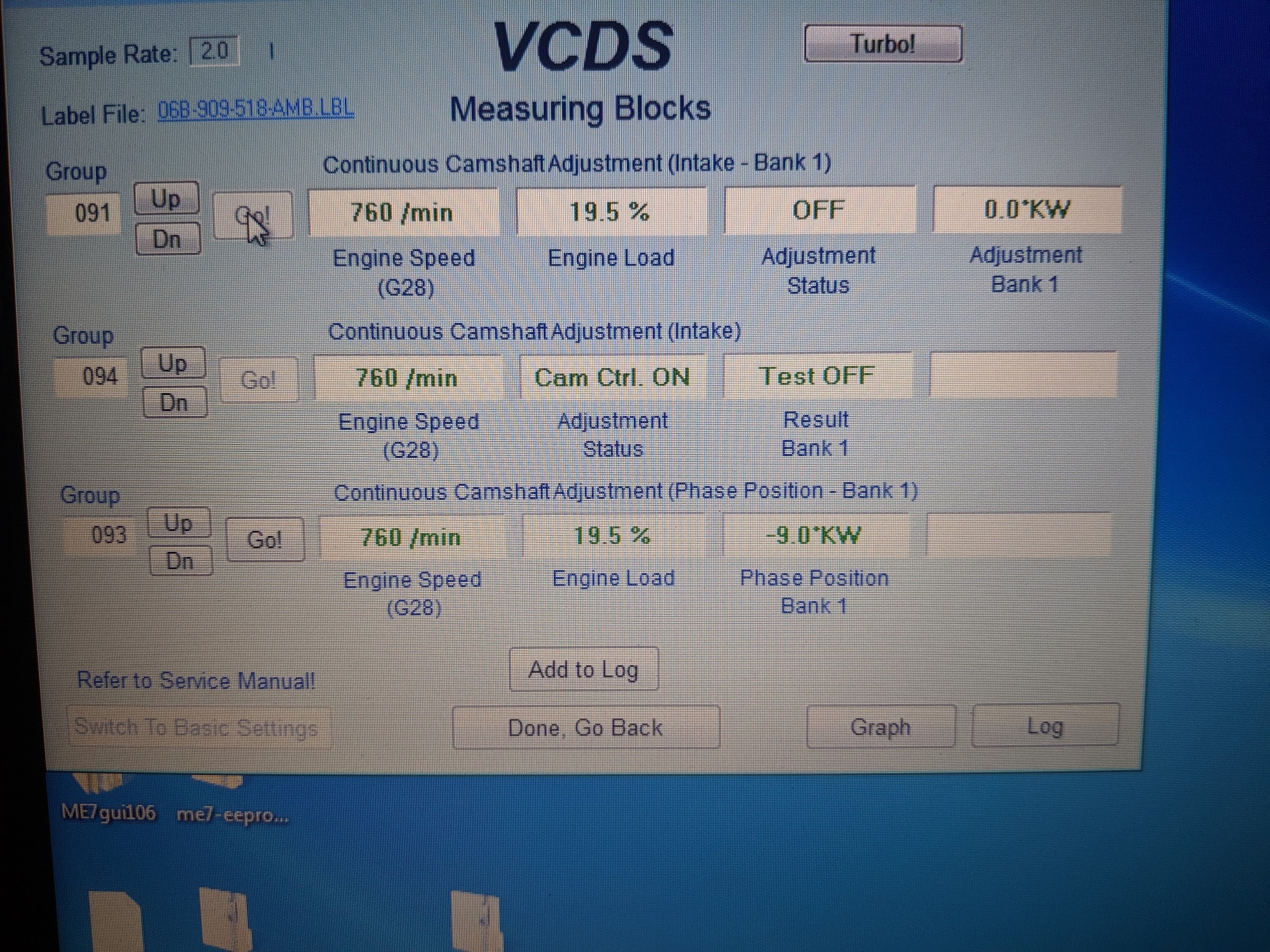

Measuring blocks provide real-time data about the engine’s operation, including cam timing. Here’s how to read them:

- Select Measuring Blocks: Click on “Measuring Blocks – 08.”

- Enter Group Numbers: Enter the appropriate group numbers (e.g., 091, 093) as indicated in the repair manual.

- Record Data: Record the values displayed for cam timing.

- Compare to Specifications: Compare the recorded values to the manufacturer’s specifications.

2.5. Interpreting the Data

Interpreting the data correctly is essential for diagnosing cam timing issues. Here’s how to understand the measurements:

- Phase Position Bank 1 (Measuring Block 093): This indicates the deviation of the camshaft position from the specified value, often displayed in degrees. The ideal value is typically 0 degrees, with a tolerance of +/- 6 degrees.

- Adjustment Bank 1 (Measuring Block 091): This shows the camshaft adjustment value. A reading of 0 degrees indicates no adjustment is applied. Deviations here might suggest issues with the camshaft adjuster.

If the values are outside the specified range, it indicates a potential cam timing issue that needs further investigation and adjustment.

3. Common Causes of Cam Timing Issues

Several factors can contribute to cam timing problems. Identifying these causes is crucial for effective diagnosis and repair.

3.1. Worn Timing Belt or Chain

The timing belt or chain is responsible for synchronizing the camshaft and crankshaft. Over time, these components can stretch or wear, leading to inaccurate cam timing.

- Timing Belt: Typically made of reinforced rubber, timing belts can degrade over time due to heat and wear.

- Timing Chain: Made of metal links, timing chains are more durable but can still stretch or develop slack.

3.2. Faulty Camshaft Adjuster

Many modern engines use a camshaft adjuster (also known as a variable valve timing (VVT) system) to optimize valve timing based on engine speed and load. A faulty adjuster can cause cam timing issues.

- Oil Supply Issues: Proper oil pressure is crucial for the adjuster’s operation.

- Solenoid Malfunctions: The solenoid controls the adjuster’s movement and can fail.

- Internal Damage: Physical damage to the adjuster components can impair its function.

3.3. Incorrect Installation of Timing Components

Improper installation of timing components, such as the timing belt or chain, can lead to significant cam timing issues.

- Misaligned Marks: Ensuring all timing marks are correctly aligned is critical.

- Incorrect Tension: Proper tension on the timing belt or chain is essential for accurate timing.

- Using Incorrect Tools: Using the wrong tools can lead to damage or misalignment during installation.

3.4. Sensor Malfunctions

Camshaft and crankshaft position sensors provide critical data to the ECU. Malfunctions in these sensors can lead to incorrect cam timing readings and adjustments.

- Dirty Sensors: Contaminants can interfere with sensor readings.

- Damaged Wiring: Damaged or corroded wiring can cause signal disruptions.

- Complete Failure: Sensors can fail completely, providing no signal to the ECU.

4. Adjusting Cam Timing with VCDS: A Detailed Walkthrough

Adjusting cam timing with VCDS requires a careful and methodical approach. This section provides a detailed walkthrough to guide you through the process.

4.1. Safety Precautions

Before starting any work on the engine, it’s crucial to take necessary safety precautions:

- Disconnect Battery: Disconnect the negative terminal of the battery.

- Wear Safety Gear: Wear safety glasses and gloves.

- Work in a Well-Ventilated Area: Ensure adequate ventilation to avoid exposure to harmful fumes.

- Use Proper Lifting Equipment: If lifting the vehicle, use jack stands to support it securely.

4.2. Locating Timing Marks

Identifying and aligning the timing marks is essential for accurate cam timing adjustments.

- Consult Repair Manual: Refer to the vehicle’s repair manual for the exact location of the timing marks.

- Crankshaft Pulley: Locate the timing mark on the crankshaft pulley.

- Camshaft Gears: Find the timing marks on the camshaft gears.

- Align Marks: Rotate the engine manually until all timing marks align according to the manual.

4.3. Using Camshaft and Crankshaft Locking Tools

Camshaft and crankshaft locking tools hold the engine in the correct position during timing adjustments.

- Install Crankshaft Locking Tool: Insert the crankshaft locking tool to secure the crankshaft at TDC.

- Install Camshaft Locking Tools: Install the camshaft locking tools to hold the camshafts in the correct position.

- Verify Alignment: Double-check that all timing marks are still aligned.

4.4. Loosening and Adjusting Camshaft Gears

Loosening and adjusting the camshaft gears allows for precise cam timing adjustments.

- Loosen Camshaft Gear Bolts: Loosen the bolts on the camshaft gears slightly.

- Adjust Camshaft Position: Use specialized tools to adjust the camshaft position as needed.

- Monitor VCDS: Use VCDS to monitor the cam timing values in real-time.

- Tighten Bolts: Once the desired cam timing is achieved, tighten the camshaft gear bolts to the specified torque.

4.5. Final Verification with VCDS

After making adjustments, final verification with VCDS ensures the cam timing is within specifications.

- Reconnect VCDS: Reconnect VCDS to the vehicle.

- Read Measuring Blocks: Read the cam timing values in the measuring blocks again.

- Compare to Specifications: Ensure the values are within the manufacturer’s specifications.

- Test Drive: Perform a test drive to check for any performance issues.

5. Advanced Techniques for VCDS Cam Timing

For experienced technicians, advanced techniques can further refine cam timing adjustments.

5.1. Dynamic Cam Timing Adjustments

Dynamic cam timing adjustments involve making changes while the engine is running to optimize performance under various conditions.

- Real-Time Monitoring: Use VCDS to monitor cam timing values in real-time.

- Adjusting on the Fly: Make small adjustments to the camshaft position while observing the engine’s response.

- Data Logging: Log data to analyze the effects of different cam timing settings.

5.2. Using VCDS for Variable Valve Timing (VVT) System Diagnostics

VCDS can be used to diagnose issues with the Variable Valve Timing (VVT) system.

- Check VVT Solenoid: Test the VVT solenoid for proper operation.

- Monitor VVT Angle: Monitor the VVT angle in the measuring blocks.

- Perform Output Tests: Use VCDS to perform output tests on the VVT system.

5.3. Troubleshooting Common VCDS Cam Timing Errors

Troubleshooting common errors ensures efficient problem-solving.

- Incorrect Adaptation Values: Reset adaptation values if necessary.

- Sensor Signal Issues: Check sensor signals for continuity and accuracy.

- Mechanical Problems: Inspect the timing components for mechanical issues.

6. Best Practices for Maintaining Optimal Cam Timing

Maintaining optimal cam timing involves adopting best practices to prevent issues and ensure long-term performance.

6.1. Regular Inspections and Maintenance

Regular inspections and maintenance are crucial for preventing cam timing issues.

- Check Timing Belt/Chain: Inspect the timing belt or chain for wear and tear.

- Monitor Sensor Performance: Monitor the performance of camshaft and crankshaft position sensors.

- Inspect Camshaft Adjuster: Inspect the camshaft adjuster for proper operation.

6.2. Using High-Quality Replacement Parts

Using high-quality replacement parts ensures reliability and longevity.

- OEM Parts: Use Original Equipment Manufacturer (OEM) parts whenever possible.

- Reputable Brands: Choose replacement parts from reputable brands.

- Avoid Counterfeit Parts: Be cautious of counterfeit parts that may not meet quality standards.

6.3. Following Manufacturer Specifications

Following manufacturer specifications ensures accurate adjustments and prevents damage.

- Torque Specifications: Adhere to specified torque values when tightening bolts.

- Timing Marks: Align timing marks according to the manufacturer’s instructions.

- Adjustment Procedures: Follow the recommended adjustment procedures.

6.4. Keeping Up with Software Updates

Keeping VCDS software updated ensures compatibility and access to the latest features.

- Regular Updates: Regularly update the VCDS software to the latest version.

- Firmware Updates: Update the VCDS interface firmware as needed.

- Compatibility: Ensure the software is compatible with the vehicle’s ECU.

7. How CARDIAGTECH.NET Can Help You with VCDS Cam Timing

CARDIAGTECH.NET offers a range of solutions to help you with VCDS cam timing adjustments, from providing high-quality diagnostic tools to offering expert support.

7.1. High-Quality Diagnostic Tools

CARDIAGTECH.NET provides access to high-quality diagnostic tools, including VCDS, to ensure accurate cam timing adjustments.

- Genuine VCDS: We offer genuine VCDS tools for reliable performance.

- Wide Range of Tools: We provide a wide range of diagnostic tools to meet your specific needs.

- Latest Technology: Our tools incorporate the latest technology for accurate and efficient diagnostics.

7.2. Expert Support and Training

CARDIAGTECH.NET offers expert support and training to help you master VCDS cam timing adjustments.

- Experienced Technicians: Our team includes experienced technicians who can provide guidance and support.

- Training Programs: We offer training programs to enhance your skills and knowledge.

- Technical Documentation: Access comprehensive technical documentation to assist you in your work.

7.3. Cost-Effective Solutions

CARDIAGTECH.NET provides cost-effective solutions to help you optimize your cam timing adjustments without breaking the bank.

- Competitive Pricing: We offer competitive pricing on our diagnostic tools and services.

- Value for Money: Our solutions provide excellent value for money.

- Long-Term Savings: Accurate cam timing adjustments can lead to long-term savings in fuel and maintenance costs.

7.4. Enhancing Efficiency and Accuracy

By utilizing CARDIAGTECH.NET’s tools and expertise, you can enhance the efficiency and accuracy of your cam timing adjustments.

- Streamlined Workflow: Our tools streamline your workflow, reducing the time required for adjustments.

- Precise Adjustments: Achieve precise cam timing adjustments for optimal engine performance.

- Reduced Errors: Minimize the risk of errors and rework.

8. Real-World Examples of VCDS Cam Timing Adjustments

Examining real-world examples can provide valuable insights into the practical application of VCDS cam timing adjustments.

8.1. Case Study 1: Resolving a Rough Idle

Problem: A 2015 Audi A4 with a 2.0L engine exhibited a rough idle and a check engine light. VCDS showed a cam timing deviation of -10 degrees.

Solution:

- Diagnosis: The technician used VCDS to confirm the cam timing issue.

- Inspection: A visual inspection revealed a worn timing chain.

- Repair: The timing chain was replaced, and the cam timing was adjusted to 0 degrees using VCDS.

- Result: The rough idle was resolved, and the check engine light was cleared.

8.2. Case Study 2: Improving Fuel Economy

Problem: A 2012 Volkswagen Golf with a 1.4L engine had poor fuel economy. VCDS indicated a cam timing deviation of +8 degrees.

Solution:

- Diagnosis: VCDS confirmed the cam timing issue.

- Inspection: The technician found a faulty camshaft adjuster.

- Repair: The camshaft adjuster was replaced, and the cam timing was adjusted to 0 degrees using VCDS.

- Result: The fuel economy improved significantly.

8.3. Case Study 3: Enhancing Engine Performance

Problem: A 2018 Skoda Octavia with a 1.8L engine lacked power. VCDS showed a cam timing deviation of -7 degrees.

Solution:

- Diagnosis: VCDS confirmed the cam timing issue.

- Inspection: The technician found misaligned timing marks due to a previous repair.

- Repair: The timing marks were correctly aligned, and the cam timing was adjusted to 0 degrees using VCDS.

- Result: The engine performance was restored.

9. The Future of Cam Timing Technology

The future of cam timing technology is poised for significant advancements, promising even greater precision, efficiency, and adaptability.

9.1. Advancements in Variable Valve Timing (VVT) Systems

Future VVT systems will likely incorporate more sophisticated control algorithms and wider adjustment ranges.

- Continuous VVT: Continuous VVT systems allow for infinite adjustment of valve timing, offering greater control over engine performance.

- Electromagnetic Actuation: Electromagnetic actuators offer faster and more precise control over valve timing.

- Cylinder Deactivation: Integrating VVT with cylinder deactivation technologies can further improve fuel economy.

9.2. Integration with Artificial Intelligence (AI)

AI can be used to optimize cam timing based on real-time data and driving conditions.

- Predictive Algorithms: AI can predict optimal cam timing settings based on driving patterns.

- Adaptive Learning: AI can learn from past data to continuously improve cam timing performance.

- Remote Diagnostics: AI can be used for remote diagnostics and troubleshooting of cam timing issues.

9.3. Improved Sensor Technology

Advancements in sensor technology will provide more accurate and reliable data for cam timing adjustments.

- High-Resolution Sensors: High-resolution sensors provide more detailed data about camshaft and crankshaft positions.

- Wireless Sensors: Wireless sensors offer greater flexibility in sensor placement and data transmission.

- Self-Diagnostic Sensors: Self-diagnostic sensors can detect and report potential issues.

9.4. Enhanced Diagnostic Tools

Future diagnostic tools will offer more advanced features for cam timing adjustments.

- Augmented Reality (AR): AR can provide visual guidance during cam timing adjustments.

- Cloud Connectivity: Cloud connectivity allows for remote access to diagnostic data and software updates.

- User-Friendly Interfaces: Improved user interfaces will make diagnostic tools easier to use.

10. Frequently Asked Questions (FAQs) About VCDS Cam Timing

Here are some frequently asked questions about VCDS cam timing, designed to provide quick and helpful answers.

10.1. What is the ideal cam timing value in VCDS?

The ideal cam timing value in VCDS is typically 0 degrees, with a tolerance of +/- 6 degrees.

10.2. How often should I check my cam timing with VCDS?

You should check your cam timing with VCDS during regular maintenance intervals, such as every 30,000 miles, or if you notice any symptoms of incorrect cam timing.

10.3. Can I adjust cam timing with VCDS on all vehicles?

VCDS is primarily used for Volkswagen Audi Group (VAG) vehicles. Check the VCDS compatibility list to ensure your vehicle is supported.

10.4. What happens if my cam timing is too far out of specification?

If your cam timing is too far out of specification, it can lead to reduced power, poor fuel economy, rough idle, and increased emissions.

10.5. Is it necessary to use locking tools when adjusting cam timing?

Yes, using camshaft and crankshaft locking tools is essential to ensure the engine is held in the correct position during timing adjustments.

10.6. Can I perform a dynamic cam timing adjustment with VCDS?

Yes, VCDS allows for dynamic cam timing adjustments, which involve making changes while the engine is running to optimize performance.

10.7. What are the common causes of cam timing issues?

Common causes of cam timing issues include a worn timing belt or chain, a faulty camshaft adjuster, incorrect installation of timing components, and sensor malfunctions.

10.8. How can CARDIAGTECH.NET help me with VCDS cam timing?

CARDIAGTECH.NET offers high-quality diagnostic tools, expert support, and training to help you master VCDS cam timing adjustments.

10.9. What safety precautions should I take when adjusting cam timing?

Safety precautions include disconnecting the battery, wearing safety gear, working in a well-ventilated area, and using proper lifting equipment.

10.10. How do I keep my VCDS software up to date?

You can keep your VCDS software up to date by regularly checking for updates on the Ross-Tech website and following the installation instructions.

Ready to optimize your vehicle’s cam timing with precision? Contact CARDIAGTECH.NET today for expert advice and top-quality diagnostic tools. Our team is ready to help you enhance your vehicle’s performance and efficiency. Don’t let cam timing issues hold you back—reach out now and experience the CARDIAGTECH.NET difference. Call us at +1 (641) 206-8880, visit our website at CARDIAGTECH.NET, or stop by our location at 276 Reock St, City of Orange, NJ 07050, United States. We’re here to help you get the job done right.