VCDS Cam Phase Adjustment is a crucial process for ensuring optimal engine performance and efficiency. Are you experiencing issues with your engine timing after replacing components? At CARDIAGTECH.NET, we understand the complexities of engine diagnostics and offer the tools you need for precise adjustments. Explore advanced diagnostic equipment to resolve timing discrepancies, enhance engine performance, and improve fuel economy.

1. Understanding VCDS Cam Phase Adjustment

Cam phase adjustment, often performed using VCDS (VAG-COM Diagnostic System), involves fine-tuning the position of the camshaft relative to the crankshaft. This adjustment is essential for optimizing engine timing, which directly impacts performance, fuel efficiency, and emissions. When the cam phase is misaligned, it can lead to a range of issues, including reduced power, rough idling, and increased fuel consumption.

1.1 What is Cam Phase?

Cam phase refers to the angular relationship between the camshaft and the crankshaft in an internal combustion engine. The camshaft controls the opening and closing of the engine’s valves, while the crankshaft translates the linear motion of the pistons into rotational motion. Precise synchronization between these two components is critical for proper engine operation.

1.2 The Role of VCDS in Cam Phase Adjustment

VCDS is a diagnostic tool used to read and interpret data from a vehicle’s Engine Control Unit (ECU). It allows technicians to monitor various engine parameters, including cam phase position, and make necessary adjustments to ensure proper timing. With VCDS, you can view real-time data, perform adaptations, and diagnose issues related to cam phase alignment.

2. Common Symptoms of Cam Phase Misalignment

Recognizing the symptoms of cam phase misalignment is the first step in addressing the problem. Here are some common indicators:

- Reduced Engine Power: A noticeable decrease in acceleration and overall engine performance.

- Rough Idling: The engine vibrates or runs unevenly when idling.

- Increased Fuel Consumption: A significant drop in fuel economy.

- Check Engine Light: The malfunction indicator lamp (MIL) illuminates, indicating a problem with the engine.

- Error Codes: Diagnostic trouble codes (DTCs) related to cam position sensors or timing issues.

3. Identifying the Root Cause of Cam Phase Issues

Before attempting to adjust the cam phase, it’s essential to identify the underlying cause of the problem. Several factors can contribute to cam phase misalignment, including:

- Timing Belt or Chain Issues: Worn or stretched timing belts or chains can cause timing inaccuracies.

- Camshaft Position Sensor Failure: A faulty sensor can provide incorrect data to the ECU, leading to misalignment.

- Crankshaft Position Sensor Failure: Similar to the camshaft sensor, a malfunctioning crankshaft sensor can disrupt timing.

- Oil Pressure Problems: Insufficient oil pressure can affect the hydraulic cam chain tensioner, leading to timing issues.

- Mechanical Damage: Damage to the camshaft, crankshaft, or related components can cause misalignment.

4. Step-by-Step Guide to VCDS Cam Phase Adjustment

Adjusting the cam phase using VCDS requires a systematic approach. Follow these steps to ensure accurate and effective adjustment:

4.1 Preparation and Safety Measures

- Gather Necessary Tools: Ensure you have VCDS software, a compatible interface cable, and basic hand tools.

- Safety First: Work in a well-ventilated area and disconnect the negative battery terminal to prevent electrical accidents.

- Consult Repair Manuals: Refer to the vehicle-specific repair manual for detailed instructions and torque specifications.

4.2 Connecting VCDS to the Vehicle

- Install VCDS Software: Install the VCDS software on your laptop or computer.

- Connect Interface Cable: Plug the VCDS interface cable into the OBD-II port of your vehicle and the USB port of your computer.

- Turn on the Ignition: Turn the ignition key to the “on” position, but do not start the engine.

4.3 Accessing Engine Control Unit (ECU)

- Launch VCDS: Open the VCDS software on your computer.

- Select Control Module: Choose the “Select Control Module” option from the main menu.

- Select Engine: Select the “Engine” control module from the list.

4.4 Reading and Interpreting Cam Phase Data

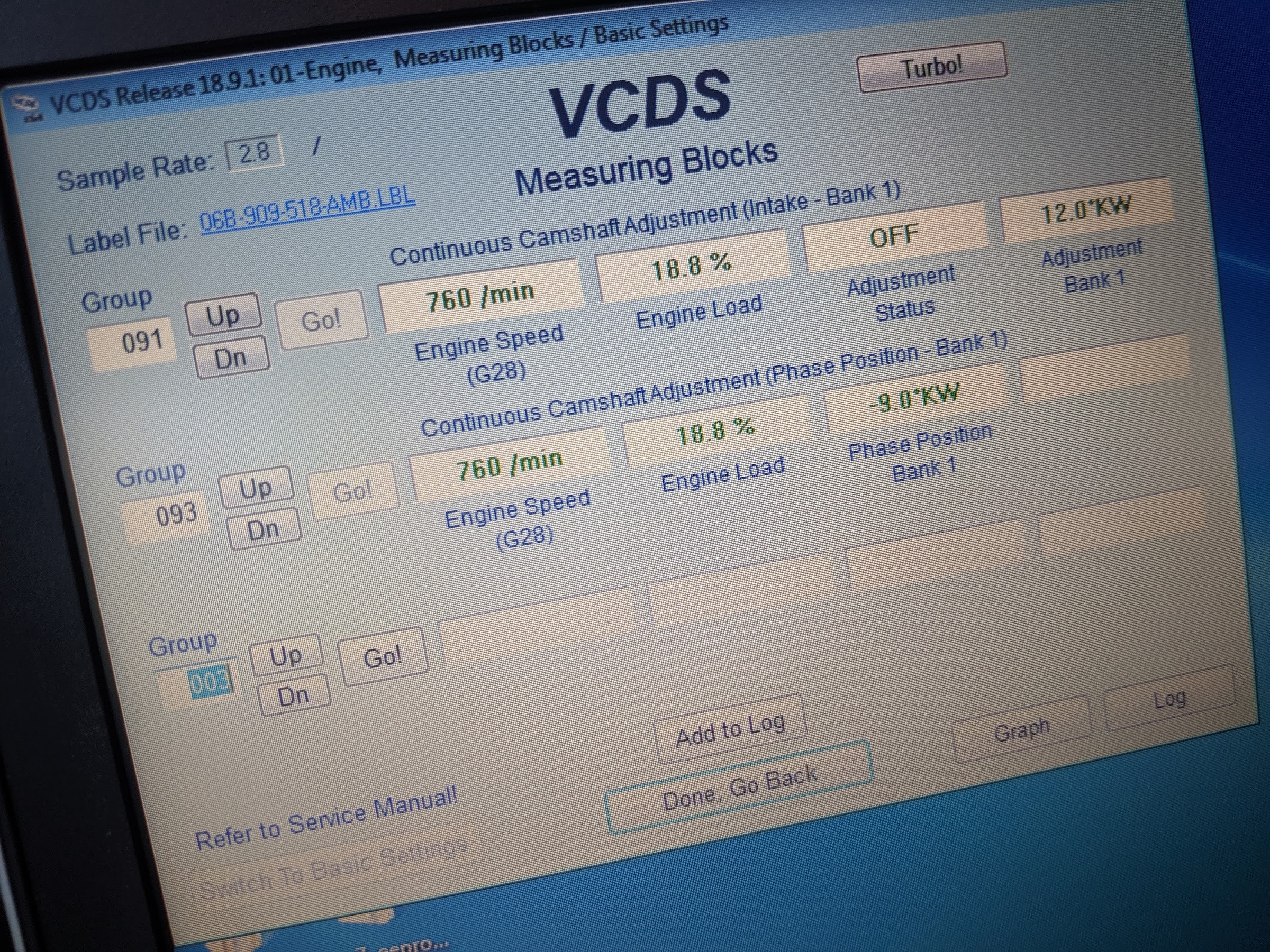

- Access Measuring Blocks: Click on the “Measuring Blocks” button to view real-time engine data.

- Identify Relevant Blocks: Enter the measuring block numbers that correspond to cam phase position (e.g., Block 093, Phase Position Bank 1).

- Record Initial Values: Note the initial cam phase values before making any adjustments.

4.5 Performing Cam Phase Adjustment

- Access Basic Settings: Click on the “Basic Settings” button.

- Select Adjustment Function: Enter the basic setting number that corresponds to cam phase adjustment (refer to the repair manual for the correct number).

- Follow On-Screen Instructions: Follow the on-screen instructions provided by VCDS to perform the adjustment. This may involve starting the engine and allowing the system to automatically adjust the cam phase.

- Monitor Values: Continuously monitor the cam phase values in the measuring blocks to ensure they are within the specified tolerance.

4.6 Verifying and Saving Adjustments

- Verify Adjustment: After the adjustment is complete, verify that the cam phase values are within the acceptable range (+/- 6 degrees is often cited).

- Save Settings: Save the new settings by clicking on the “Done, Go Back” button.

- Clear Error Codes: Clear any DTCs related to cam phase misalignment using the “Fault Codes – 02” function.

- Test Drive: Perform a test drive to ensure the engine is running smoothly and the symptoms have been resolved.

5. Essential Tools for VCDS Cam Phase Adjustment at CARDIAGTECH.NET

Having the right tools is essential for performing accurate and efficient cam phase adjustments. At CARDIAGTECH.NET, we offer a range of high-quality diagnostic equipment to meet your needs.

| Tool | Description | Key Features |

|---|---|---|

| VCDS Diagnostic System | Comprehensive diagnostic tool for VAG vehicles, providing access to real-time data, adaptations, and fault code reading and clearing. | User-friendly interface, extensive vehicle coverage, accurate data readings. |

| Timing Belt/Chain Kit | Complete kit including timing belt or chain, tensioner, and idler pulleys. | High-quality materials, precise fitment, ensures reliable timing. |

| Camshaft Alignment Tool | Tool used to hold the camshafts in the correct position during timing belt or chain replacement. | Ensures accurate camshaft alignment, prevents timing errors. |

| Crankshaft Locking Tool | Tool used to lock the crankshaft in the correct position during timing belt or chain replacement. | Prevents crankshaft movement, ensures accurate timing. |

| Camshaft Position Sensor | Sensor that monitors the position of the camshaft and provides data to the ECU. | Accurate readings, durable construction, ensures proper engine timing. |

| Crankshaft Position Sensor | Sensor that monitors the position of the crankshaft and provides data to the ECU. | Accurate readings, durable construction, ensures proper engine timing. |

| Oil Pressure Tester Kit | Kit used to measure oil pressure in the engine. | Accurate measurement, helps diagnose oil pressure-related timing issues. |

| OBD-II Scanner | Generic OBD-II scanner for reading and clearing fault codes. | Compatible with a wide range of vehicles, provides basic diagnostic information. |

| Multimeter | Tool used to measure voltage, current, and resistance in electrical circuits. | Helps diagnose electrical issues related to sensors and actuators. |

| Vacuum Pump | Used to check for vacuum leaks in the engine, which can affect performance and timing. | Easy to use, helps identify vacuum leaks quickly. |

| Compression Tester | Used to measure the compression in each cylinder, which can indicate engine wear or damage. | Accurate measurement, helps assess engine health. |

| Leak Down Tester | Used to identify leaks in the cylinders, such as valve leaks or piston ring leaks. | Pinpoints leaks accurately, helps diagnose engine problems. |

| Timing Light | Used to check and adjust ignition timing. | Ensures accurate ignition timing, improves engine performance. |

| Fuel Pressure Tester | Used to measure fuel pressure in the fuel system. | Helps diagnose fuel-related issues that can affect engine performance. |

| Coolant Pressure Tester | Used to check for leaks in the cooling system. | Helps prevent overheating and engine damage. |

| Battery Load Tester | Used to test the condition of the battery and charging system. | Ensures reliable starting and electrical system performance. |

| Scan Tool with Live Data | Advanced scan tool that displays live engine data, including sensor readings and engine parameters. | Provides real-time information for accurate diagnosis. |

| Infrared Thermometer | Used to measure surface temperatures quickly and accurately. | Helps identify overheating components or areas. |

| Borescope | Used to inspect the inside of the engine cylinders without disassembling the engine. | Allows for visual inspection of cylinder walls, pistons, and valves. |

| Hydraulic Cam Chain Tensioner Tool | Specialized tool to work on the hydraulic cam chain tensioner safely and effectively. | Essential for maintaining proper timing chain tension. |

6. Common Mistakes to Avoid During Cam Phase Adjustment

Even with the right tools and knowledge, mistakes can happen. Here are some common pitfalls to avoid:

- Ignoring Repair Manuals: Always consult the vehicle-specific repair manual for detailed instructions and specifications.

- Incorrect Tool Usage: Using the wrong tools or using them improperly can damage engine components.

- Neglecting Safety Precautions: Failing to disconnect the battery or working in a poorly ventilated area can lead to accidents.

- Skipping Diagnostic Steps: Not properly diagnosing the root cause of the problem can result in repeated issues.

- Overlooking Basic Checks: Failing to check the condition of the timing belt or chain, sensors, and other components can lead to inaccurate adjustments.

7. Advanced Troubleshooting Techniques

If you’ve followed the basic adjustment steps and are still experiencing issues, consider these advanced troubleshooting techniques:

7.1 Checking Camshaft and Crankshaft Sensors

Use VCDS to monitor the signals from the camshaft and crankshaft sensors. Look for any irregularities or dropouts in the signal, which could indicate a faulty sensor.

7.2 Inspecting Timing Belt or Chain

Visually inspect the timing belt or chain for signs of wear, cracks, or damage. Check the tension and alignment of the belt or chain to ensure it is properly installed.

7.3 Analyzing Oil Pressure

Low oil pressure can affect the hydraulic cam chain tensioner, leading to timing issues. Use an oil pressure gauge to measure the oil pressure and compare it to the manufacturer’s specifications.

7.4 Performing Compression Test

A compression test can reveal issues with the engine’s cylinders, such as worn piston rings or valves, which can affect timing and performance.

8. The Importance of Regular Maintenance

Preventing cam phase issues is often easier than fixing them. Regular maintenance can help keep your engine running smoothly and prevent timing problems.

8.1 Scheduled Timing Belt or Chain Replacement

Follow the manufacturer’s recommended service intervals for timing belt or chain replacement. Replacing these components on time can prevent catastrophic engine damage.

8.2 Oil Changes and Maintenance

Regular oil changes and maintenance can help ensure proper lubrication and prevent wear on engine components, including the cam chain tensioner.

8.3 Inspecting Sensors

Periodically inspect the camshaft and crankshaft sensors for signs of damage or wear. Replace them as needed to ensure accurate timing.

9. Benefits of Professional VCDS Cam Phase Adjustment

While it’s possible to perform cam phase adjustment yourself, there are several benefits to seeking professional help:

- Expertise and Experience: Professional technicians have the knowledge and experience to accurately diagnose and adjust cam phase.

- Specialized Tools: Professional shops have access to specialized tools and equipment, such as advanced diagnostic scanners and alignment tools.

- Warranty and Guarantees: Professional repairs often come with warranties or guarantees, providing peace of mind.

- Time Savings: Professionals can complete the adjustment quickly and efficiently, saving you time and hassle.

10. VCDS Cam Phase Adjustment: Maximizing Engine Performance

Proper cam phase adjustment is essential for maximizing engine performance and efficiency. By ensuring accurate timing, you can improve power, fuel economy, and reduce emissions.

10.1 Improved Horsepower and Torque

Correct cam phase alignment optimizes the engine’s valve timing, allowing it to breathe more efficiently and produce more horsepower and torque.

10.2 Enhanced Fuel Efficiency

Optimized cam phase reduces fuel consumption by ensuring the engine is running at its most efficient state.

10.3 Reduced Emissions

Properly adjusted cam phase helps reduce emissions by ensuring complete combustion and minimizing the release of harmful pollutants.

11. Real-World Examples and Case Studies

To illustrate the importance of VCDS cam phase adjustment, here are a few real-world examples and case studies:

11.1 Case Study 1: Volkswagen Jetta with Reduced Power

A Volkswagen Jetta owner reported a significant decrease in engine power and rough idling. Using VCDS, a technician discovered that the cam phase was misaligned due to a worn timing belt. After replacing the timing belt and performing a cam phase adjustment, the engine regained its power and ran smoothly.

11.2 Case Study 2: Audi A4 with Check Engine Light

An Audi A4 owner experienced a check engine light and increased fuel consumption. VCDS revealed a fault code related to the camshaft position sensor. After replacing the sensor and performing a cam phase adjustment, the check engine light disappeared, and fuel economy improved.

11.3 Case Study 3: Skoda Octavia with Timing Issues

A Skoda Octavia exhibited timing issues after a recent engine repair. The technician used VCDS to monitor the cam phase and found it was significantly out of alignment. By adjusting the cam phase using VCDS, the engine’s timing was corrected, resolving the performance issues.

12. Frequently Asked Questions (FAQ) About VCDS Cam Phase Adjustment

-

What is VCDS?

VCDS (VAG-COM Diagnostic System) is a software and hardware tool used for diagnosing and adjusting various systems in Volkswagen, Audi, Skoda, and SEAT vehicles.

-

Why is cam phase adjustment important?

Cam phase adjustment ensures proper engine timing, which is crucial for optimal performance, fuel efficiency, and emissions.

-

What are the symptoms of cam phase misalignment?

Symptoms include reduced engine power, rough idling, increased fuel consumption, and a check engine light.

-

What tools are needed for VCDS cam phase adjustment?

You need VCDS software, a compatible interface cable, basic hand tools, and possibly camshaft alignment tools.

-

How often should cam phase be checked?

Cam phase should be checked during regular maintenance intervals or whenever you experience symptoms of misalignment.

-

Can I perform cam phase adjustment myself?

Yes, but it requires knowledge of engine mechanics and proper use of VCDS. Professional assistance is recommended for those unfamiliar with the process.

-

What are the common causes of cam phase misalignment?

Common causes include worn timing belts or chains, faulty sensors, oil pressure problems, and mechanical damage.

-

How do I read cam phase data using VCDS?

Use the “Measuring Blocks” function in VCDS and enter the block numbers corresponding to cam phase position (e.g., Block 093).

-

What is the acceptable range for cam phase values?

The acceptable range is typically +/- 6 degrees, but refer to the vehicle-specific repair manual for precise specifications.

-

Where can I buy quality VCDS tools and equipment?

CARDIAGTECH.NET offers a wide range of high-quality diagnostic tools and equipment, including VCDS systems and related accessories.

13. Contact CARDIAGTECH.NET for Expert Assistance

Are you ready to optimize your engine’s performance with precise cam phase adjustments? Contact CARDIAGTECH.NET today for expert advice and high-quality diagnostic tools. Our team of experienced professionals can help you select the right equipment and provide guidance on proper adjustment techniques.

Address: 276 Reock St, City of Orange, NJ 07050, United States

WhatsApp: +1 (641) 206-8880

Website: CARDIAGTECH.NET

Don’t let cam phase misalignment compromise your engine’s performance. Trust CARDIAGTECH.NET for all your diagnostic needs and experience the difference that precision and quality can make.

Take action now and contact us via WhatsApp at +1 (641) 206-8880 to discuss your needs and discover how our tools can enhance your automotive repair capabilities. Our experts are ready to provide immediate support and answer any questions you may have.

engine-components

engine-components

14. Understanding the Technical Aspects of Cam Phase Adjustment

To truly master VCDS cam phase adjustment, it’s important to delve into some of the more technical aspects. This includes understanding the different types of camshaft control systems, how they operate, and the specific parameters you need to monitor with VCDS.

14.1 Types of Camshaft Control Systems

There are several types of camshaft control systems used in modern vehicles. Understanding these systems is crucial for effective diagnosis and adjustment.

-

Fixed Cam Timing: In this older system, the camshaft timing is fixed and cannot be adjusted. VCDS can still be used to diagnose issues, but adjustments are limited to mechanical corrections.

-

Variable Valve Timing (VVT): VVT systems allow the camshaft timing to be adjusted dynamically based on engine speed and load. These systems use hydraulic actuators controlled by the ECU.

-

Cam Phasers: Cam phasers are a type of VVT system that allows for continuous adjustment of the camshaft timing. They are commonly used in modern engines for improved performance and fuel efficiency.

-

Dual Variable Valve Timing (DVVT): DVVT systems allow for independent adjustment of both the intake and exhaust camshafts. This provides even greater control over valve timing and engine performance.

14.2 How Cam Phasers Work

Cam phasers use hydraulic pressure to adjust the position of the camshaft relative to the crankshaft. The ECU controls the flow of oil to the phaser, which in turn adjusts the timing. Monitoring the cam phaser angle and response time with VCDS can help diagnose issues with the phaser itself or the oil control system.

14.3 Key VCDS Parameters to Monitor

When performing cam phase adjustment, there are several key parameters to monitor with VCDS:

| Parameter | Description | Importance |

|---|---|---|

| Camshaft Adaptation Angle | The actual angle of the camshaft relative to the crankshaft. | Indicates the current cam phase position. |

| Camshaft Requested Angle | The angle the ECU is requesting from the cam phaser. | Shows the target cam phase position. |

| Cam Phaser Duty Cycle | The percentage of time the oil control valve is open. | Indicates the ECU’s control over the cam phaser. |

| Oil Pressure | The oil pressure supplied to the cam phaser. | Low oil pressure can affect the phaser’s ability to adjust the timing accurately. |

| Camshaft Position Sensor Signal | The signal from the camshaft position sensor. | Indicates the sensor’s accuracy and reliability. |

| Crankshaft Position Sensor Signal | The signal from the crankshaft position sensor. | Ensures synchronization between camshaft and crankshaft. |

| Engine Speed (RPM) | The current engine speed. | Cam phase adjustments are often dependent on engine speed. |

| Engine Load | The current engine load. | Cam phase adjustments are also dependent on engine load. |

| Intake Air Temperature (IAT) | The temperature of the intake air. | Extreme temperatures can affect engine performance and cam phase adjustments. |

| Coolant Temperature | The temperature of the engine coolant. | Proper coolant temperature is essential for accurate cam phase adjustments. |

| Mass Airflow (MAF) | The amount of air entering the engine. | Used to calculate the correct fuel mixture and optimize cam phase. |

| Throttle Position | The position of the throttle. | Indicates the driver’s demand for power and affects cam phase adjustments. |

| Ignition Timing Advance | The amount of ignition timing advance. | Correct ignition timing is essential for optimal engine performance and cam phase adjustments. |

| Fuel Trim Values (Short Term and Long Term) | The adjustments the ECU is making to the fuel mixture. | High fuel trim values can indicate issues that affect cam phase, such as vacuum leaks or fuel delivery problems. |

| Oxygen Sensor Readings | The readings from the oxygen sensors. | Used to monitor the effectiveness of combustion and adjust cam phase for optimal emissions. |

| Fault Codes | Any diagnostic trouble codes (DTCs) related to the camshaft or crankshaft position. | Indicates specific issues that need to be addressed. |

14.4 Diagnosing Common Cam Phaser Issues

Several common issues can affect cam phaser performance. Here are some troubleshooting tips:

- Cam Phaser Stuck: If the cam phaser is stuck in one position, it may be due to a lack of oil pressure or a mechanical failure within the phaser. Check the oil pressure and inspect the phaser for damage.

- Cam Phaser Overshooting: If the cam phaser is overshooting the requested angle, it may be due to a faulty oil control valve or a problem with the ECU. Check the oil control valve and the ECU’s control signals.

- Cam Phaser Noise: A noisy cam phaser can indicate wear or damage within the phaser. Inspect the phaser for signs of wear and replace it if necessary.

- Incorrect Readings: If the cam position sensor is providing incorrect readings, it may be due to a faulty sensor or a wiring issue. Check the sensor and the wiring for damage.

15. Maximizing Your Investment in Diagnostic Tools

Investing in high-quality diagnostic tools is essential for any automotive technician. Here are some tips for maximizing your investment:

15.1 Choose the Right Tools

Select tools that are appropriate for the types of vehicles you work on and the types of repairs you perform. CARDIAGTECH.NET offers a wide range of diagnostic tools to meet your specific needs.

15.2 Keep Your Tools Updated

Make sure to keep your diagnostic tools updated with the latest software and firmware. This will ensure that they are compatible with the latest vehicles and have the most accurate data.

15.3 Maintain Your Tools

Properly maintain your diagnostic tools to ensure they last for years to come. Clean them regularly and store them in a safe place when not in use.

15.4 Get Training

Attend training courses to learn how to use your diagnostic tools effectively. This will help you diagnose problems more quickly and accurately.

15.5 Leverage Online Resources

Take advantage of online resources, such as forums and technical support websites, to get help with troubleshooting and repairs. CARDIAGTECH.NET provides comprehensive support resources for its customers.

16. The Future of Automotive Diagnostics

The field of automotive diagnostics is constantly evolving. As vehicles become more complex, diagnostic tools must keep pace. Here are some trends to watch:

16.1 Artificial Intelligence (AI)

AI is being used to develop more advanced diagnostic tools that can automatically identify problems and suggest solutions.

16.2 Remote Diagnostics

Remote diagnostics allows technicians to diagnose and repair vehicles from a remote location. This can save time and money, and it can also provide access to specialized expertise.

16.3 Augmented Reality (AR)

AR is being used to develop tools that can overlay diagnostic information onto the vehicle, making it easier to identify problems and perform repairs.

16.4 Cloud-Based Diagnostics

Cloud-based diagnostics allows technicians to access diagnostic data and tools from anywhere with an internet connection. This can improve collaboration and efficiency.

17. Why CARDIAGTECH.NET is Your Best Choice

Choosing the right supplier for your diagnostic tools is crucial. CARDIAGTECH.NET offers several advantages:

17.1 High-Quality Products

We offer a wide range of high-quality diagnostic tools from leading manufacturers.

17.2 Competitive Prices

Our prices are competitive, and we offer discounts and promotions to help you save money.

17.3 Expert Support

Our team of experienced professionals can provide expert support and guidance.

17.4 Fast Shipping

We offer fast shipping to get you the tools you need quickly.

17.5 Customer Satisfaction

We are committed to customer satisfaction, and we offer a money-back guarantee if you are not satisfied with your purchase.

18. Final Thoughts: Mastering VCDS Cam Phase Adjustment

VCDS cam phase adjustment is a critical skill for any automotive technician working on VAG vehicles. By understanding the technical aspects of cam phase, using the right tools, and following best practices, you can ensure optimal engine performance and customer satisfaction. CARDIAGTECH.NET is your trusted partner for all your diagnostic needs, providing high-quality tools, expert support, and a commitment to your success.

Don’t wait—take control of your engine’s performance. Contact CARDIAGTECH.NET today and equip yourself with the tools and knowledge to excel in automotive diagnostics.