Navigating the complexities of your vehicle’s onboard diagnostic system can be daunting, especially when faced with trouble codes like P0341. This code, defined as Camshaft Position Sensor “A” Circuit Range/Performance, indicates a potential issue within your engine’s timing and sensor system. As an auto repair expert at autelfrance.com, I’m here to break down what this code means, what the symptoms are, and how to approach diagnosing and resolving it.

Decoding P0341: What Does It Really Mean?

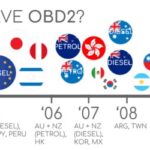

P0341 is a generic powertrain code that falls under the OBD-II (On-Board Diagnostics II) system. This system is standardized across most modern vehicles and is designed to monitor various aspects of your car’s performance and emissions. When your vehicle’s Powertrain Control Module (PCM) – the brain of your engine management system – detects an anomaly in the signal from the Camshaft Position Sensor (CPS), it triggers the P0341 code.

The camshaft position sensor plays a crucial role in engine operation. It’s responsible for informing the PCM about the position and rotational speed of the camshaft. This information is vital for:

- Precise Fuel Injection Timing: Ensuring fuel is injected at the optimal moment for efficient combustion.

- Accurate Ignition Timing: Firing the spark plugs at the correct time for each cylinder.

- Sequential Fuel Injection and Misfire Detection: Enabling advanced engine control strategies.

The CPS typically works in conjunction with a reluctor wheel or tone ring attached to the camshaft. As the camshaft rotates, the reluctor wheel’s teeth or notches pass by the sensor, generating a pulsed signal. The PCM interprets this signal to determine camshaft position. Code P0341 arises when the PCM detects that this signal is erratic, inconsistent, or falls outside the expected range of performance. It’s essentially saying the signal from the camshaft position sensor isn’t making sense.

Recognizing the Symptoms of a P0341 Code

While a P0341 code might not always cause immediate, dramatic symptoms, it’s crucial to address it promptly to prevent potential engine damage or performance issues. You might experience some or none of the following symptoms:

- Check Engine Light Illumination: This is the most common and immediate sign. The malfunction indicator lamp (MIL), often called the check engine light, will illuminate on your dashboard.

- Reduced Fuel Economy: Inefficient combustion due to improper timing can lead to a noticeable decrease in miles per gallon.

- Engine Stalling or Rough Running: The PCM may struggle to maintain consistent engine operation without accurate camshaft position data, leading to stalling, rough idling, or hesitation.

- Difficulty Starting or No-Start Condition: In more severe cases, if the PCM cannot reliably determine camshaft position, it may prevent the engine from starting altogether.

- Limp Mode Operation: To protect the engine from potential damage, the PCM might engage a “limp-in” or “limp-home” mode. This mode restricts engine power and speed.

It’s important to note that the severity of symptoms can vary depending on the nature and intermittency of the sensor issue. Sometimes the problem is intermittent, meaning the symptoms might come and go, making diagnosis trickier.

Pinpointing the Causes of P0341

Several factors can trigger a P0341 code. A systematic diagnostic approach is necessary to accurately identify the root cause. Here are the most common culprits:

- Faulty Camshaft Position Sensor: The sensor itself can fail due to age, wear and tear, or internal electrical issues. This is often the first suspect.

- Wiring and Connector Problems: The wiring harness and connectors associated with the camshaft position sensor are exposed to engine heat and vibrations. This can lead to:

- Damaged Wiring: Chafing, fraying, or breaks in the wiring insulation can cause shorts or open circuits.

- Poor Connections: Corrosion, loose terminals, or bent pins within the sensor or PCM connectors can disrupt the signal.

- Proximity to Ignition Wires: If the sensor wiring is routed too close to spark plug wires, electromagnetic interference can distort the sensor signal.

- Reluctor Wheel Damage: The reluctor wheel (or tone ring) on the camshaft needs to be in good condition to generate a clean signal. Damage such as:

- Bent or Missing Teeth: Physical damage can disrupt the sensor signal pattern.

- Debris Accumulation: Metal shavings or other debris can interfere with the sensor’s ability to read the reluctor wheel.

- PCM Issues (Less Common): While less frequent, a faulty PCM can misinterpret a good sensor signal or incorrectly set the P0341 code. PCM failures are usually diagnosed after ruling out other possibilities.

- Timing Chain/Belt Problems: In rare instances, if the timing chain or belt has stretched or jumped a tooth, it can cause a misalignment between the crankshaft and camshaft positions, potentially triggering P0341. This is usually accompanied by other codes and more severe engine performance issues.

- Extended Cranking: In some cases, prolonged cranking of the engine during startup attempts can temporarily set a P0341 code, especially if the battery voltage is low or the starting system is weak. This is less likely to be a persistent issue if the engine starts and runs normally afterward.

Diagnosing and Repairing P0341: A Step-by-Step Approach

Troubleshooting P0341 requires a methodical approach. Here’s a step-by-step guide to help you diagnose and potentially fix the issue:

- Verify the Code: Use an OBD-II scanner to confirm the presence of the P0341 code and check for any other related codes. Record all codes present.

- Visual Inspection of Wiring and Connectors:

- Carefully inspect the camshaft position sensor wiring and connector. Look for any signs of damage: chafing, melting, breaks, or corrosion.

- Ensure the connector is securely attached to the sensor and PCM.

- Check the wiring routing and ensure it’s not too close to high-voltage ignition components like spark plug wires.

- Sensor Testing:

- Resistance Test: Use a multimeter to check the sensor’s resistance according to the vehicle manufacturer’s specifications. An out-of-range reading indicates a faulty sensor.

- Signal Test (Oscilloscope or Scan Tool): Ideally, use an oscilloscope to visualize the sensor’s signal waveform while the engine is running or cranking. A scan tool with live data capabilities can also be used to monitor the sensor’s output voltage or frequency. Look for a clean, consistent signal pattern. Erratic or absent signals suggest a sensor or wiring problem.

- Reluctor Wheel Inspection:

- If possible, visually inspect the reluctor wheel through the sensor port. Look for missing teeth, damage, or excessive debris. In some cases, you might need to remove the sensor for a better view.

- If the reluctor wheel is not accessible, further inspection might require removing engine components like the valve cover or intake manifold, depending on vehicle design.

- Wiring Circuit Testing:

- Use a multimeter to check for continuity and shorts in the sensor wiring circuit, from the sensor connector to the PCM connector.

- Verify proper voltage supply and ground to the sensor.

- PCM Diagnosis (Last Resort): Only after thoroughly checking the sensor, wiring, and reluctor wheel should you suspect the PCM. PCM testing often requires specialized equipment and expertise and might be best left to a professional technician.

- Component Replacement and Verification:

- Sensor Replacement: If the sensor tests faulty, replace it with a new, quality sensor.

- Wiring Repair: Repair any damaged wiring or connectors. Ensure proper connections are made.

- Reluctor Wheel Repair/Replacement: If the reluctor wheel is damaged, it may require camshaft replacement in some cases.

- After any repair, clear the P0341 code using a scan tool and test drive the vehicle to ensure the code does not return and the symptoms are resolved.

Important Note: In some rare cases, particularly in older vehicles or certain engine designs, a P0341 code might be triggered by issues unrelated to the camshaft position sensor itself. For example, severe misfires due to faulty spark plugs, wires, or ignition coils can sometimes indirectly cause this code to set. Therefore, consider these basic ignition components if initial diagnosis doesn’t pinpoint a sensor or wiring problem.

Seeking Professional Help

Diagnosing and repairing OBD-II codes can be complex. If you are not comfortable performing these diagnostic steps or if the P0341 code persists after your initial attempts at repair, it’s always advisable to consult a qualified automotive technician. They have the expertise, specialized tools, and diagnostic equipment to accurately pinpoint the root cause of the problem and perform the necessary repairs effectively.

Understanding OBD-II codes like P0341 empowers you to be a more informed car owner. By understanding the potential causes and symptoms, you can communicate effectively with your mechanic and ensure your vehicle receives the proper care it needs to stay running smoothly.

Related Camshaft Trouble Codes: P0340, P0342, P0343, P0345, P0347, P0348, P0349, P0365, P0366, P0367, P0368, P0369, P0390, P0391, P0392, P0393, P0394.

Do you still have questions about the P0341 code? Join our FREE car repair forums to ask questions and get personalized advice from experienced mechanics and automotive enthusiasts! Post your question now!

Disclaimer: This information is for informational purposes only and should not be considered professional repair advice. Always consult a qualified technician for diagnosis and repair.