The On-Board Diagnostics II (OBD2) system is crucial for modern vehicle maintenance and diagnostics. As a standardized protocol, it allows mechanics and enthusiasts to access a wealth of data about a vehicle’s health and performance. If you’re delving into OBD2 diagnostics, you’ve likely encountered messages and Parameter IDs (PIDs). Understanding these is key to effective troubleshooting and data analysis. In this guide, we’ll break down the essentials of OBD2, focusing on the specific query related to “Obdii Message 7e0 Pid Supported 46” and how to interpret it within the broader OBD2 framework.

What is OBD2 and Why is it Important?

OBD2 is essentially your car’s self-reporting system. It’s a standardized way for vehicles to communicate diagnostic information. Think of it as a universal language that allows diagnostic tools to talk to your car’s computer. The system was initially developed for emissions control, mandated by the California Air Resources Board (CARB) starting in 1991. Over time, it became mandatory across the US and EU for various vehicle types.

When that check engine light illuminates on your dashboard, it’s OBD2 at work. A mechanic uses an OBD2 scanner, connecting it to the 16-pin OBD2 connector typically found under the dashboard near the steering wheel. This connection allows the scanner to send requests and receive responses containing diagnostic trouble codes (DTCs) and real-time data like speed, engine temperature, and more. This standardized access significantly streamlines the diagnostic process, making it faster and more efficient to identify and resolve vehicle issues.

OBD2 Evolution: From Emissions to Data Access

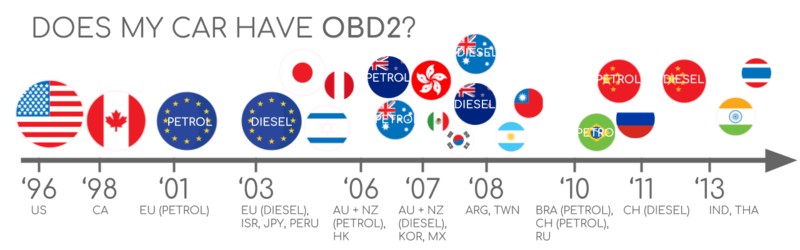

The history of OBD2 reflects a growing need for standardized vehicle diagnostics. Originating in California for emissions monitoring, it was gradually adopted and mandated globally:

- 1996: OBD2 becomes mandatory in the USA for cars and light trucks.

- 2001: Required in the EU for gasoline cars (EOBD).

- 2003: Extended to diesel cars in the EU (EOBD).

- 2008: US mandates ISO 15765-4 (CAN) as the foundation for OBD2.

- 2010: OBD2 becomes mandatory for heavy-duty vehicles in the US.

This progression highlights the increasing importance of OBD2 not just for emissions, but also for broader vehicle diagnostics and data accessibility. However, the future of OBD2 is evolving, with trends like OBD3 and alternative protocols emerging.

OBD2 Standards: The Technical Foundation

OBD2 operates as a higher-layer protocol, much like a language spoken over a communication channel. In most modern cars, this channel is the Controller Area Network (CAN bus). Think of CAN bus as the phone line and OBD2 as the language spoken on that line. This is similar to other CAN-based protocols like J1939, CANopen, and NMEA 2000.

The OBD2 standards define everything from the physical OBD2 connector to the communication protocols and Parameter IDs (PIDs). These standards are often represented in a 7-layer OSI model, detailing the communication stack. Key standards include SAE J1979 (or ISO 15031-5) for diagnostic services and SAE J1962 (or ISO 15031-3) for the connector. It’s worth noting that SAE standards are primarily US-focused, while ISO standards are more globally oriented, often with technical equivalence.

The OBD2 Connector: Your Access Point

The OBD2 connector, standardized as SAE J1962, is your physical interface to the vehicle’s diagnostic system. This 16-pin connector, usually located near the steering wheel, provides power and communication channels.

Key aspects of the OBD2 connector include:

- Location: Typically under the dashboard, but location can vary.

- Pin 16: Provides battery power.

- Pinout: Varies depending on the communication protocol used.

- CAN bus: Pins 6 (CAN-High) and 14 (CAN-Low) are commonly used for CAN communication.

There are two main types, Type A (cars) and Type B (heavy-duty vehicles), primarily differing in voltage (12V vs 24V) and sometimes baud rates. Type B connectors have a physical interruption in the groove, making Type B adapters compatible with both sockets, while Type A adapters only fit Type A sockets.

OBD2 and CAN Bus: The Communication Backbone

Since 2008, CAN bus (ISO 15765-4) has been the mandatory lower-layer protocol for OBD2 in US vehicles. ISO 15765-4, also known as Diagnostics over CAN (DoCAN), specifies how OBD2 communication is implemented over CAN.

Key ISO 15765-4 specifications include:

- Bit-rate: 250K or 500K.

- CAN IDs: 11-bit or 29-bit.

- Specific CAN IDs: Reserved for OBD2 requests and responses.

- Data Length: 8 bytes per CAN frame.

- Cable Length: Maximum 5 meters for the OBD2 adapter cable.

OBD2 communication over CAN relies on request/response message pairs. For 11-bit CAN IDs, functional addressing uses ID 0x7DF to query all OBD2-compliant Electronic Control Units (ECUs). Physical addressing uses IDs 0x7E0-0x7E7 to target specific ECUs. Responses are typically sent using IDs 0x7E8-0x7EF, with 0x7E8 commonly used by the Engine Control Module (ECM). For 29-bit CAN, functional addressing uses 0x18DB33F1, and responses range from 0x18DAF100 to 0x18DAF1FF, often seen as PGN 0xDA00 in J1939 terminology.

Understanding “OBDII Message 7E0 PID Supported 46”

Now, let’s focus on the core keyword: “obdii message 7e0 pid supported 46”.

-

7E0: This is a CAN ID. As discussed, 0x7E0 is a standard 11-bit CAN ID used for OBD2 requests, specifically for physical addressing to the Engine Control Module (ECM). This means the request is directed at a specific ECU, in this case, likely the engine control unit.

-

PID Supported 46: This refers to a query about supported Parameter IDs (PIDs). In OBD2 service 0x01 (Show current data), PID 0x00 (PIDs supported [01-20]) is a crucial PID. When you request PID 0x00, the ECU responds with a bitmask indicating which PIDs in the range 0x01 to 0x20 are supported by that ECU. Following this logic, PID 0x20 (PIDs supported [21-40]) indicates support for PIDs 0x21-0x40, and PID 0x40 (PIDs supported [41-60]) indicates support for PIDs 0x41-0x60.

Therefore, “PID Supported 46” likely refers to checking if PID 0x46 (or potentially a PID in the range 0x41-0x60) is supported by the ECU. To do this, you would first send an OBD2 request with:

- CAN ID: 0x7E0 (to target the ECM directly) or 0x7DF (functional request to all ECUs)

- Data bytes:

02 01 20(for PID 0x20, checking PIDs 0x21-0x40 support) or02 01 40(for PID 0x40, checking PIDs 0x41-0x60 support). While PID 0x40 is more likely given “PID Supported 46”, it’s possible the user meant to check support in the 0x21-0x40 range first.

The response to PID 0x20 or 0x40 will contain a 4-byte bitmask. To check if PID 0x46 is supported, you would need to look at the bitmask returned in response to PID 0x40. PID 0x46 falls within the range covered by PID 0x40 (PIDs 0x41-0x60).

Decoding OBD2 Messages and PID Support

Let’s illustrate with an example of checking if PID 0x46 (Engine coolant temperature) is supported.

-

Request: Send an OBD2 message with CAN ID 0x7E0 (or 0x7DF), data bytes

02 01 40. This is a request to the ECM (or all ECUs) for service 0x01 (show current data), PID 0x40 (PIDs supported [41-60]). -

Response: The ECM (or an ECU) responds with CAN ID 0x7E8 (or 0x7E9, etc.). The data bytes will include:

06 41 40 <byte1> <byte2> <byte3> <byte4>.06: Number of data bytes following.41: Response to service 0x01 (0x01 + 0x40).40: The PID requested (0x40).<byte1> <byte2> <byte3> <byte4>: This 4-byte bitmask indicates PID support.

-

Interpreting the Bitmask: Each bit in the 4-byte bitmask corresponds to a PID.

- Byte 1 represents PIDs 0x41-0x48 (bit 0 for PID 0x41, bit 1 for PID 0x42, and so on).

- Byte 2 represents PIDs 0x49-0x50.

- Byte 3 represents PIDs 0x51-0x58.

- Byte 4 represents PIDs 0x59-0x60.

To check if PID 0x46 is supported, you need to examine bit 5 of byte 1 (since PID 0x46 is the 6th PID in the 0x41-0x48 range, starting from bit 0). If this bit is set to ‘1’, then PID 0x46 is supported. If it’s ‘0’, PID 0x46 is not supported by that ECU.

Practical OBD2 Data Logging and Decoding

To practically work with OBD2 data, you’ll need tools to send requests, receive responses, and decode the data. Tools like the CANedge CAN bus data logger, combined with an OBD2-DB9 adapter cable, can be used to log OBD2 data.

Steps for logging and decoding OBD2 data:

-

Test Bit-rate and IDs: Use ISO 15765-4 guidelines to determine the correct bit-rate (250K or 500K) and CAN IDs for your vehicle. Tools can send test frames to validate the communication setup.

-

Identify Supported PIDs: Send PID 0x00, 0x20, 0x40, etc., requests to determine which PIDs are supported by your vehicle. Our OBD2 PID lookup tool can help decode the bitmask responses.

-

Configure PID Requests: Create a transmit list of PIDs you want to log. For efficient logging, consider using physical addressing (e.g., CAN ID 0x7E0) and spacing out requests to avoid overwhelming the ECUs.

-

DBC Decoding: Use a DBC file (like our free OBD2 DBC file) to decode the raw CAN data into human-readable values. Remember that OBD2 decoding often involves “extended multiplexing,” requiring both CAN ID and PID information for proper signal identification.

Beyond Single Frame: Multi-Frame OBD2 Communication

While many OBD2 requests and responses fit within a single CAN frame (8 bytes of data), some data, like the Vehicle Identification Number (VIN) or Diagnostic Trouble Codes (DTCs), require multi-frame communication using ISO-TP (ISO 15765-2).

Example: Requesting VIN

To get the VIN, you use OBD2 mode 0x09 (Vehicle information) and PID 0x02 (Vehicle Identification Number). This typically involves a multi-frame response as the VIN exceeds 8 bytes.

Example: Diagnostic Trouble Codes (DTCs)

Requesting DTCs (mode 0x03) also often involves multi-frame responses, especially if multiple DTCs are stored. Each DTC is 2 bytes, so responses with more than 2 DTCs will require multiple frames.

OBD2 Data Logging Use Cases

OBD2 data has numerous applications across various sectors:

- Vehicle Telematics: Tracking fuel consumption, driving behavior, and vehicle health for fleet management or insurance purposes.

- Predictive Maintenance: Monitoring vehicle parameters to predict potential failures and schedule maintenance proactively.

- Real-time Diagnostics: Streaming OBD2 data for live vehicle diagnostics and troubleshooting.

- Black Box Recording: Using OBD2 loggers as vehicle “black boxes” for accident reconstruction or warranty purposes.

Conclusion: Mastering OBD2 Diagnostics

Understanding OBD2 messages like “obdii message 7e0 pid supported 46” is crucial for anyone working with vehicle diagnostics. By grasping the fundamentals of OBD2 standards, connectors, CAN bus communication, and PID structure, you can effectively diagnose vehicle issues, log valuable data, and leverage OBD2 for a wide range of applications. Whether you are a professional mechanic, a car enthusiast, or an engineer developing automotive solutions, mastering OBD2 provides a powerful gateway to vehicle data and control.

Ready to dive deeper into OBD2 data logging?

Buy OBD2 Data Logger Now Contact us for OBD2 Solutions

Recommended for you

OBD2 DATA LOGGER: EASILY LOG & CONVERT OBD2 DATA

CANEDGE2 – PRO CAN IoT LOGGER

[