The Obdii Jack is the gateway to your car’s health, allowing technicians to diagnose issues and access real-time data through CARDIAGTECH.NET. Understanding its function and potential is key to efficient vehicle maintenance. This guide provides a comprehensive overview of the OBDII jack, its history, standards, and how it can be used for advanced diagnostics and data logging.

1. Understanding the OBDII Jack: Your Car’s Diagnostic Port

The OBDII jack, or On-Board Diagnostics II jack, serves as your vehicle’s built-in self-diagnostic system, CARDIAGTECH.NET explains. This standardized protocol enables the extraction of diagnostic trouble codes (DTCs) and real-time data through the OBDII connector. Using OBDII, car owners and technicians can obtain insightful information about car issues, vehicle performance, and diagnostic scanning.

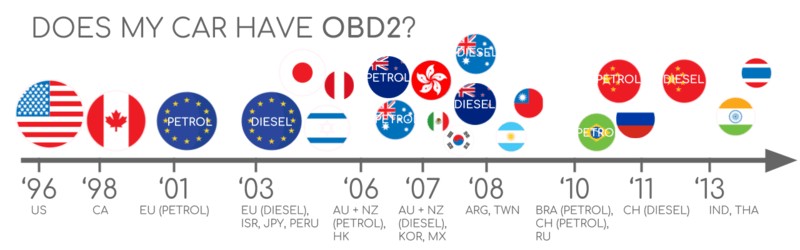

2. Is My Car OBDII Compliant? Checking Compatibility

The good news is that most modern cars are OBDII compliant! Nearly all new non-electric cars support OBDII and many operate using the CAN bus protocol. Even if there’s a 16-pin OBDII connector present in older cars, they might not fully support OBDII. Checking when and where your car was bought can indicate compliance.

| Region | Compliance Date for Cars/Light Trucks |

|---|---|

| USA | 1996 |

| EU (Gasoline) | 2001 |

| EU (Diesel) | 2003 |

3. A Brief History of OBDII: From Emissions Control to Modern Diagnostics

OBDII began in California where the California Air Resources Board (CARB) mandated OBD in all new cars from 1991 onwards for the sake of emissions control. The Society of Automotive Engineers (SAE) suggested the OBDII standard. This standardized DTCs and the OBD connector across various manufacturers.

- 1996: OBDII becomes mandatory in the USA for cars and light trucks.

- 2001: Required in the EU for gasoline cars.

- 2003: Required in the EU also for diesel cars (EOBD).

- 2005: OBDII required in the US for medium duty vehicles.

- 2008: US cars must use ISO 15765-4 (CAN) as the foundation for OBDII.

- 2010: Finally, OBDII was required in the US heavy duty vehicles.

4. The Future of OBDII: Telematics, OBD3, and Beyond

OBDII’s evolution continues with trends such as OBD3, and adaptations for electric vehicles. Telematics and remote diagnostics are also part of its future.

4.1. Electric Vehicles and OBDII

Due to the initial focus on emissions control, electric vehicles aren’t usually required to support OBDII. EVs often use OEM-specific UDS communication, making data decoding a challenge unless reverse engineering is employed. However, resources like the CARDIAGTECH.NET case studies for electric cars (Tesla, Hyundai/Kia, Nissan, VW/Skoda EVs) can offer insight.

4.2. WWH-OBD and OBDonUDS

Modern alternatives like WWH-OBD (World Wide Harmonized OBD) and OBDonUDS (OBD on UDS) are emerging to improve OBD communication using the UDS protocol. To learn more, CARDIAGTECH.NET offers an intro to UDS.

4.3. OBD3 and Telematics

OBD3 seeks to add telematics to vehicles via a small radio transponder, sending the vehicle identification number (VIN) and DTCs via WiFi to a central server. Devices like the CANedge2 and CANedge3 already facilitate this data transfer.

4.4. Third-Party Data Access

The German car industry is exploring options to limit third-party access to OBDII data, potentially collecting data on a central server. While intended to improve security, some view this as a commercial strategy.

5. Key OBDII Standards: Connector, Protocols, and Parameter IDs

OBDII includes specifications for the connector, lower-layer protocols, and parameter IDs (PIDs). The standards align within a 7-layer OSI model, involving both SAE and ISO standards for US and EU compliance.

5.1. The OBDII Connector (SAE J1962)

The 16-pin OBDII connector, specified in SAE J1962 / ISO 15031-3, provides access to car data. It’s commonly located near the steering wheel.

- Pin 16 provides battery power.

- The OBDII pinout depends on the communication protocol.

- CAN bus is the most common lower-layer protocol, using pins 6 (CAN-H) and 14 (CAN-L).

5.2. OBDII Connector Types: A vs. B

You might find type A and type B OBDII connectors. Type A is common in cars, while type B is found in medium and heavy-duty vehicles. Type B features an interrupted groove in the middle, which makes a type B OBDII adapter cable compatible with both types, but a type A cable will not fit into a type B socket.

6. OBDII and CAN Bus: ISO 15765-4 Standards

Since 2008, CAN bus has been mandatory for OBDII in US cars as per ISO 15765. ISO 15765-4 (Diagnostics over CAN or DoCAN) sets restrictions applied to the CAN standard (ISO 11898), standardizing the CAN interface with a focus on the physical, data link, and network layers.

- The CAN bus bit-rate must be either 250K or 500K.

- CAN IDs can be 11-bit or 29-bit.

- Specific CAN IDs are used for OBD requests/responses.

- The diagnostic CAN frame data length must be 8 bytes.

- The OBDII adapter cable must be max 5 meters.

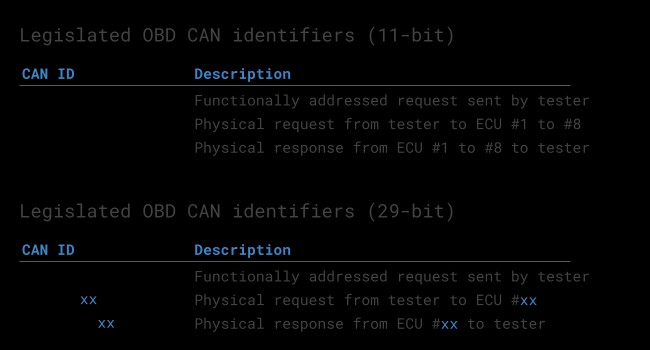

6.1. OBDII CAN Identifiers (11-bit, 29-bit)

OBDII communication involves request/response messages. In most cars, 11-bit CAN IDs are used. The ‘Functional Addressing’ ID is 0x7DF, and ECUs respond with 11-bit IDs 0x7E8-0x7EF. In some vehicles, extended 29-bit CAN identifiers may be used.

6.2. OBDII vs. Proprietary CAN Protocols

Your car’s ECUs don’t depend on OBDII to function. Each OEM uses proprietary CAN protocols. OBDII should be seen as an extra higher-layer protocol running in parallel to the OEM-specific protocol.

6.3. Bit-Rate and ID Validation

OBDII may use two bit-rates (250K, 500K) and two CAN ID lengths (11-bit, 29-bit), resulting in 4 possible combinations. ISO 15765-4 provides recommendations for an initialization sequence to determine the correct combination.

6.4. Five Lower-Layer OBDII Protocols

- ISO 15765 (CAN bus): Mandatory in US cars since 2008.

- ISO14230-4 (KWP2000): Used in 2003+ cars, especially in Asia.

- ISO 9141-2: Used in EU, Chrysler & Asian cars in 2000-04.

- SAE J1850 (VPW): Used mostly in older GM cars.

- SAE J1850 (PWM): Used mostly in older Ford cars.

7. Transporting OBDII Messages via ISO-TP (ISO 15765-2)

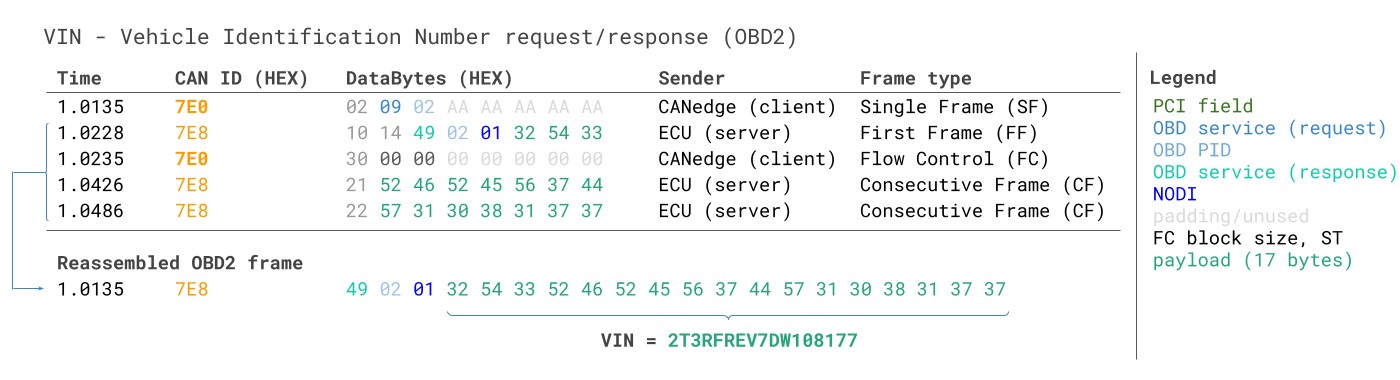

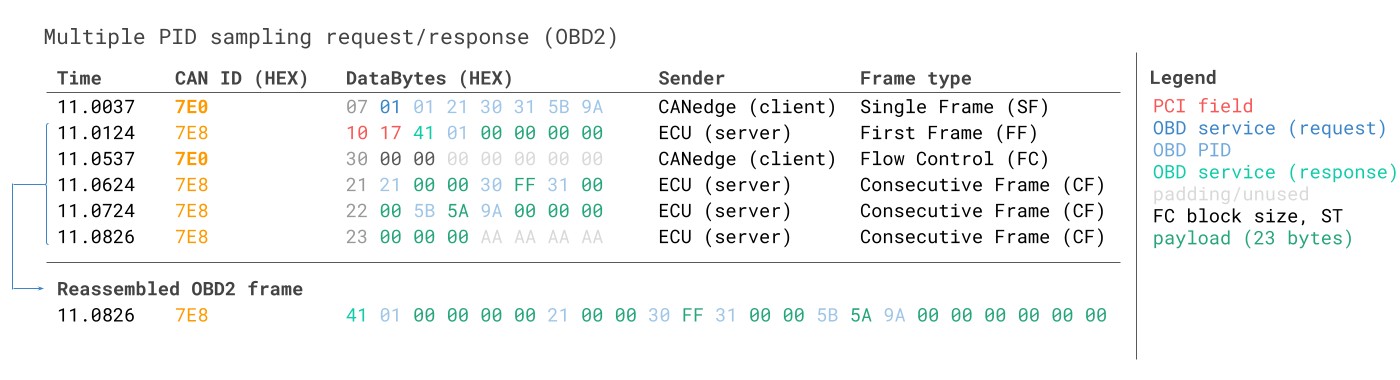

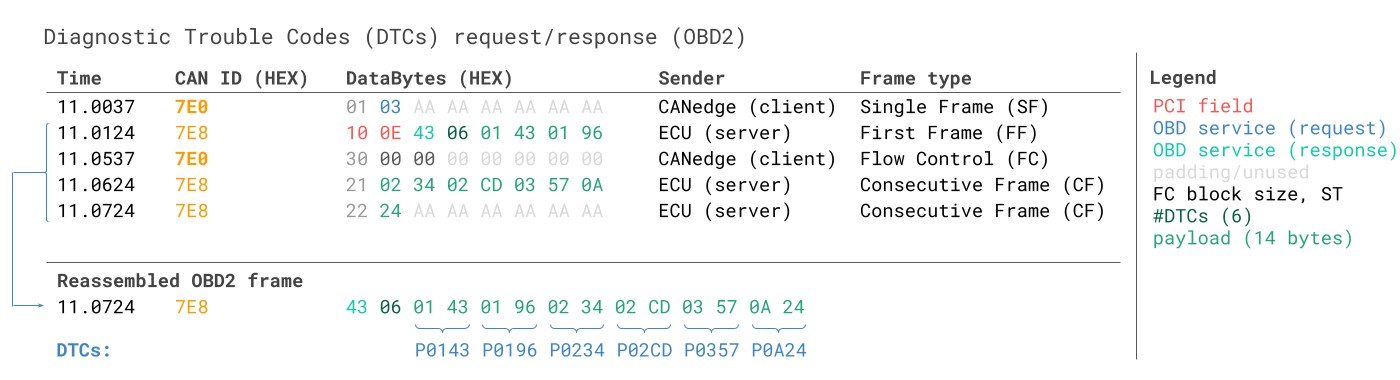

OBDII data is communicated on the CAN bus via ISO-TP (ISO 15765-2), allowing payloads exceeding 8 bytes. This is necessary for extracting the Vehicle Identification Number (VIN) or Diagnostic Trouble Codes (DTCs).

8. The OBDII Diagnostic Message (SAE J1979, ISO 15031-5)

An OBDII message consists of an identifier, data length (PCI field), and data (Mode, parameter ID (PID), and data bytes).

8.1. Example: OBDII Request/Response

An external tool requests ‘Vehicle Speed’ (PID 0x0D) and the car responds with the speed value.

8.2. The 10 OBDII Services (aka Modes)

There are 10 OBDII diagnostic services (modes). Mode 0x01 displays real-time data, while others show/clear DTCs or show freeze frame data. Vehicles don’t have to support all modes.

8.3. OBDII Parameter IDs (PIDs)

Each OBDII mode includes PIDs. For instance, mode 0x01 has ~200 standardized PIDs with real-time data on speed, RPM, and fuel level. However, most vehicles only support a subset. If an emissions-related ECU supports any OBDII services, it must support mode 0x01 PID 0x00.

8.4. OBDII PID Overview Tool

SAE J1979 and ISO 15031-5 appendices provide scaling information for standard OBDII PIDs. The CARDIAGTECH.NET OBDII PID overview tool can also assist in constructing request frames and decoding responses.

9. How to Log and Decode OBDII Data

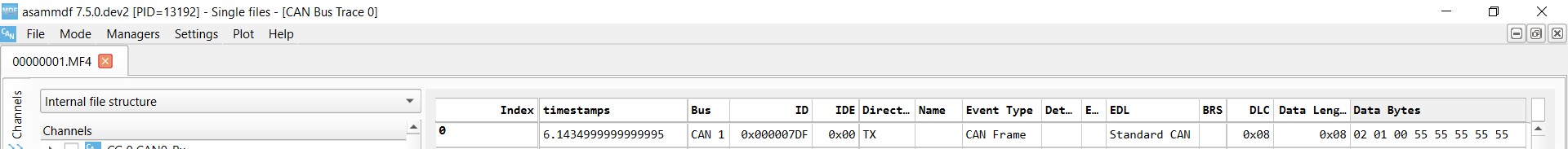

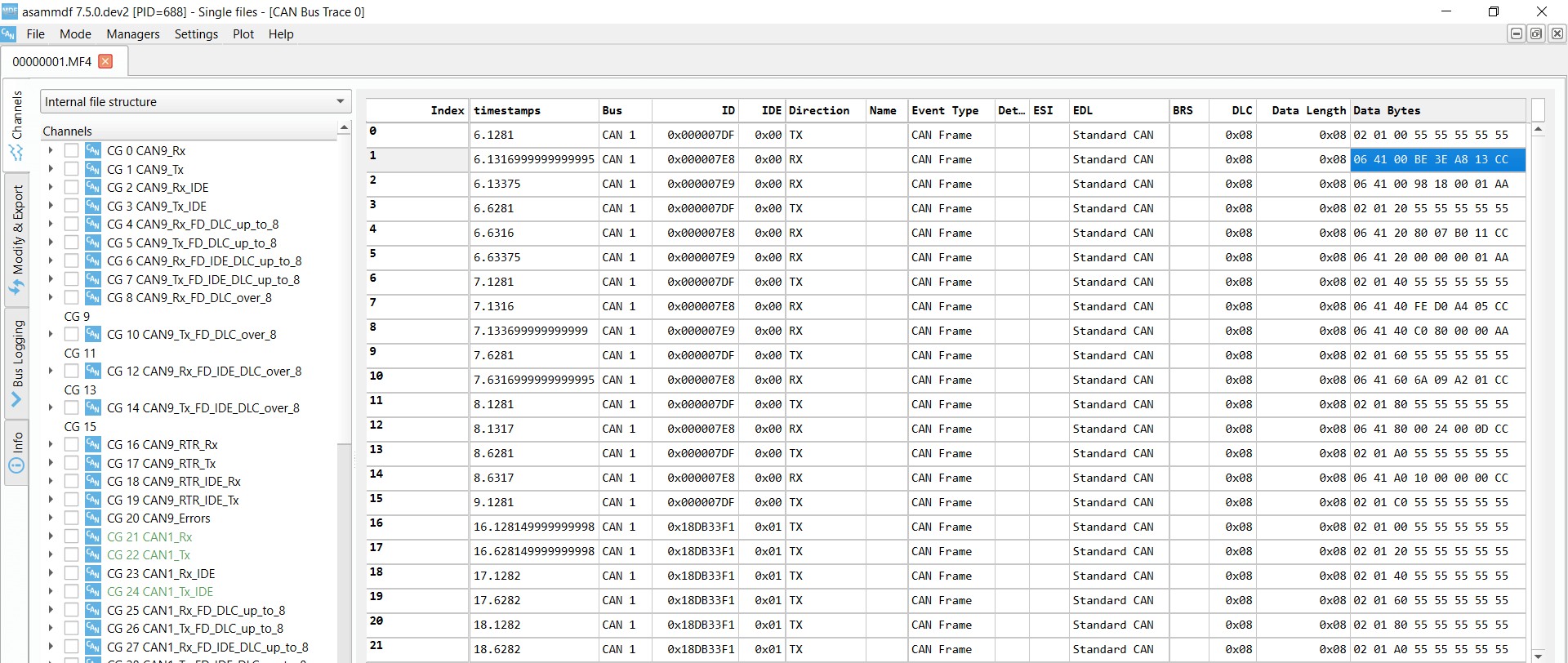

Logging OBDII data using a tool like the CANedge CAN bus data logger involves configuration and connection.

9.1. Test Bit-Rate, IDs & Supported PIDs

Determine the bit-rate and IDs used by the vehicle, then test with the CANedge, sending CAN frames at 500K (or 250K if unsuccessful). Send multiple ‘Supported PIDs’ requests and review the results.

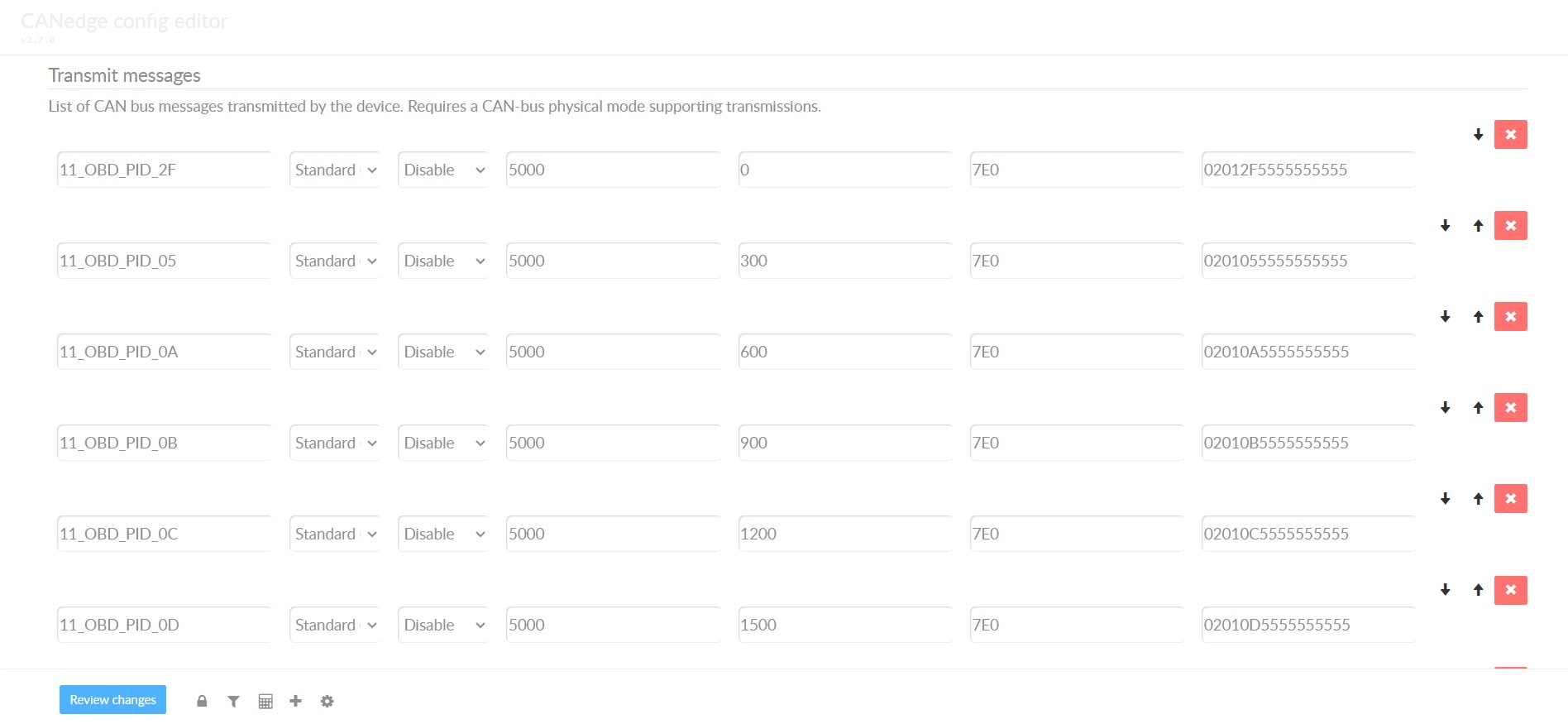

9.2. Configure OBDII PID Requests

Configure your transmit list with PIDs of interest, considering CAN IDs, spacing, battery drain, and filters.

9.3. DBC Decode Raw OBDII Data

Decode the raw OBDII data into physical values using the ISO 15031-5/SAE J1979 standards. The CARDIAGTECH.NET OBDII DBC file can assist in DBC decoding.

10. OBDII Multi-Frame Examples (ISO-TP)

OBDII data is communicated using the ISO-TP. Multi-frame communication requires flow control frames, and CAN software/API tools that support ISO-TP.

10.1. Example 1: OBDII Vehicle Identification Number (VIN)

To extract the VIN using OBDII, use mode 0x09 and PID 0x02.

10.2. Example 2: OBDII Multi-PID Request (6x)

External tools can request up to 6 mode 0x01 OBDII PIDs in a single request frame.

10.3. Example 3: OBDII Diagnostic Trouble Codes (DTCs)

Request emissions-related DTCs using mode 0x03. The 2-byte DTC value is split into a category and a 4-digit code.

11. OBDII Data Logging – Use Case Examples

OBDII data is used for reducing fuel costs, improving driving, testing prototype parts, insurance, real-time diagnostics, predictive maintenance, and serving as a vehicle black box.

Logging data from cars

OBD2 data from cars can e.g. be used to reduce fuel costs, improve driving, test prototype parts and insurance

obd2 logger

Real-time car diagnostics

OBD2 interfaces can be used to stream human-readable OBD2 data in real-time, e.g. for diagnosing vehicle issues

obd2 streaming

Predictive maintenance

Cars and light trucks can be monitored via IoT OBD2 loggers in the cloud to predict and avoid breakdowns

predictive maintenance

Vehicle blackbox logger

An OBD2 logger can serve as a ‘blackbox’ for vehicles or equipment, providing data for e.g. disputes or diagnostics

can bus blackbox

CARDIAGTECH.NET is here to help!

Are you struggling with any of the following?

- The physical demands of automotive repair?

- The constant need to update your skills with new automotive technology?

- Finding the right tools for the job?

CARDIAGTECH.NET understands the challenges you face. We offer solutions to enhance your efficiency, accuracy, and safety. Contact us today for a consultation on the best OBDII tools to meet your needs! We’re here to help you enhance your efficiency, accuracy, and safety.

Contact CARDIAGTECH.NET Today!

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- WhatsApp: +1 (641) 206-8880

- Website: CARDIAGTECH.NET

Frequently Asked Questions (FAQ) About the OBDII Jack

1. What exactly is an OBDII jack?

The OBDII (On-Board Diagnostics II) jack is a standardized port in your car that allows access to the vehicle’s self-diagnostic system. It provides a way to retrieve diagnostic trouble codes (DTCs) and real-time data, facilitating faster and more accurate troubleshooting.

2. Where can I find the OBDII jack in my car?

Typically, the OBDII jack is located within reach of the driver’s seat, often under the dashboard, near the steering wheel column. Some cars may have it hidden behind a small panel.

3. What kind of information can I get from the OBDII jack?

Through the OBDII jack, you can access a wealth of information, including:

- Diagnostic trouble codes (DTCs) that indicate specific problems with the car.

- Real-time data such as engine speed (RPM), vehicle speed, engine temperature, and fuel level.

- Emission-related data, useful for ensuring your car meets environmental standards.

4. What tools do I need to use the OBDII jack?

To access and interpret data from the OBDII jack, you typically need an OBDII scanner or scan tool. These tools range from basic code readers to advanced diagnostic equipment with features like data logging and graphing.

5. Is it safe to leave an OBDII scanner plugged in all the time?

While it’s generally safe, leaving an OBDII scanner plugged in constantly can drain the car’s battery, especially if the car is not driven frequently. Some scanners also have the potential to interfere with the car’s electronic systems.

6. Can I use the OBDII jack to improve my car’s performance?

Yes, to some extent. By monitoring real-time data, you can identify areas where your car is not performing optimally. Additionally, some advanced tools allow you to adjust certain engine parameters to enhance performance or fuel efficiency. However, modifications should be done with caution and knowledge.

7. Does every car have the same OBDII pinout?

While the OBDII connector is standardized with 16 pins, the function of some pins may vary depending on the communication protocol used by the car. CAN bus is the most common protocol, but older cars may use different ones.

8. Can I clear the “Check Engine” light using an OBDII scanner?

Yes, most OBDII scanners have the ability to clear diagnostic trouble codes (DTCs) and turn off the “Check Engine” light. However, it’s important to address the underlying issue that triggered the light, rather than just clearing the code.

9. What is the difference between OBDII and OBD1?

OBD1 was an earlier, less standardized version of on-board diagnostics. OBDII is more comprehensive, standardized across manufacturers, and provides more detailed diagnostic information.

10. Are there any legal restrictions on using OBDII data?

The use of OBDII data is generally unrestricted for personal diagnostics and vehicle maintenance. However, using this data for commercial purposes, such as building a data-driven service, may face restrictions from car manufacturers seeking to protect their data.