Obdii Catalyst monitor is crucial for ensuring your vehicle meets emission standards, and at CARDIAGTECH.NET, we understand the frustrations that come with incomplete monitors and failed smog checks. This guide delves into how to get your catalyst monitor ready, interpret drive cycles, and troubleshoot common issues, providing expert insights and practical solutions to help you navigate the complexities of OBDII systems. With the right knowledge and tools, you can optimize your vehicle’s performance and contribute to a cleaner environment.

1. Understanding the OBDII Catalyst Monitor

The On-Board Diagnostics II (OBDII) system in your car includes a catalyst monitor designed to assess the efficiency of the catalytic converter. The catalyst monitor runs a series of tests to ensure the catalytic converter is functioning correctly and reducing harmful emissions. All monitors, including the catalyst monitor, rely on sensors for their data. Typically, the oxygen (O2) sensors play a vital role in this process. The Engine Control Module (ECM) uses data from these sensors to evaluate the performance of the catalytic converter.

1.1. What Does the Catalyst Monitor Do?

The catalyst monitor assesses the catalytic converter’s ability to reduce pollutants. It checks the efficiency of the converter by comparing the oxygen levels before and after the catalytic converter.

1.2. Why Is the Catalyst Monitor Important?

A functioning catalyst monitor is essential for several reasons:

- Emissions Compliance: Ensures your vehicle meets emission standards, which is crucial for passing smog checks.

- Environmental Protection: Helps reduce harmful emissions, contributing to cleaner air.

- Vehicle Performance: A faulty catalytic converter can affect engine performance and fuel efficiency.

1.3. Common Issues Leading to Incomplete Monitors

Several factors can prevent the catalyst monitor from completing its tests:

- Recent Battery Disconnection: Clearing codes or disconnecting the battery resets the monitors.

- Faulty Sensors: Malfunctioning O2 sensors or other related sensors can prevent the monitor from running.

- Drive Cycle Incompletion: The specific driving conditions required to run the monitor may not have been met.

- Underlying Mechanical Issues: Engine misfires, vacuum leaks, or other mechanical problems can interfere with the monitor’s operation.

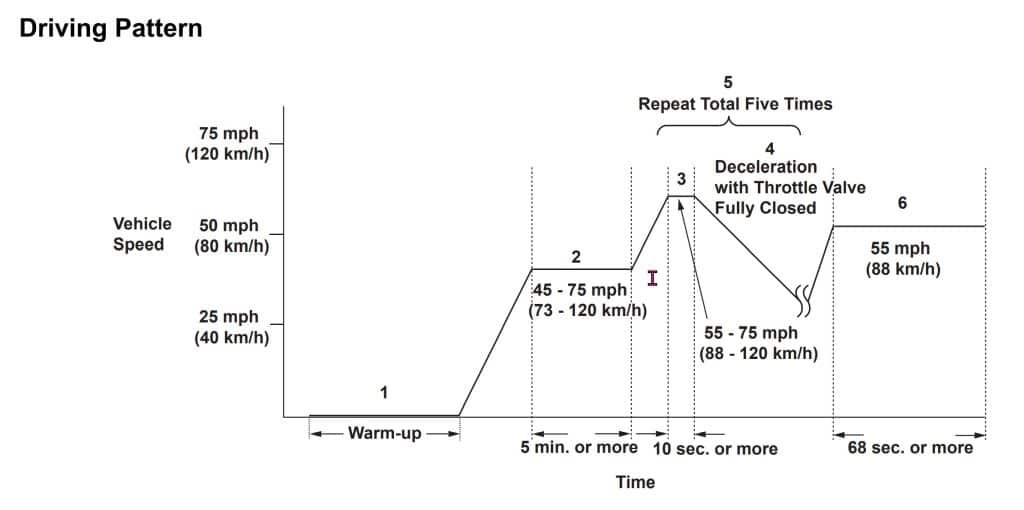

Catalyst monitor graph

Catalyst monitor graph

2. Decoding the Catalyst Monitor Drive Cycle

A drive cycle is a set of specific driving conditions designed to run the OBDII monitors, including the catalyst monitor. These cycles vary depending on the vehicle’s make, model, and year.

2.1. What Is a Drive Cycle?

A drive cycle includes various driving maneuvers such as idling, acceleration, deceleration, and steady cruising. The ECM monitors these conditions to initiate and complete the catalyst monitor test.

2.2. Finding the Correct Drive Cycle for Your Vehicle

Locating the correct drive cycle is crucial for getting the catalyst monitor to run. Here are several ways to find this information:

- Vehicle’s Service Manual: The service manual provides detailed instructions for performing a drive cycle.

- Online Technical Information Websites: Subscribing to technical information websites like techinfo.toyota.com, techinfo.subaru.com, techinfo.honda.com, nissan-techinfo.com, and mazdaserviceinfo.com gives you access to manufacturer-specific drive cycles.

- CARDIAGTECH.NET: As a customer, CARDIAGTECH.NET can provide you with a printed copy of the drive cycle for your specific vehicle.

- Online Forums: While forums can offer some information, verify the credibility of the source.

2.3. Common Drive Cycle Steps

While specific drive cycles vary, here are some common steps you might encounter:

- Cold Start: Start the vehicle and allow it to idle for a specified period.

- Steady Cruise: Drive at a steady speed (e.g., 45-55 mph) for a set duration.

- Acceleration and Deceleration: Perform controlled accelerations and decelerations.

- Idling: Allow the vehicle to idle again for a specified period.

2.4. Example Drive Cycle

Here’s an example of a catalyst monitor drive cycle for a Toyota vehicle:

- Start the engine and let it idle for two minutes.

- Drive at 50 mph for eight minutes.

- Let the car idle for one minute.

- Drive at 55 mph for seven minutes.

- Idle for two minutes.

2.5. Tips for Completing a Drive Cycle Successfully

- Follow Instructions Precisely: Adhere to the speed, time, and other conditions specified in the drive cycle.

- Use Cruise Control: Cruise control can help maintain a steady speed during the cruise phase.

- Avoid Abrupt Stops: Smooth accelerations and decelerations are crucial.

- Monitor Conditions: Use an OBDII scanner to monitor the status of the catalyst monitor during the drive cycle.

2.6. Overcoming Challenges in Executing Drive Cycles

Executing a drive cycle isn’t always straightforward. You may encounter obstacles such as traffic, road conditions, or specific vehicle requirements. Here are strategies to address these challenges:

- Traffic Considerations: Choose times and routes with minimal traffic to maintain consistent speeds and avoid frequent stops. Early mornings or late evenings on highways are often ideal.

- Road Conditions: Opt for flat, straight roads to facilitate steady cruising speeds. Avoid hilly or winding roads that can disrupt the drive cycle.

- Vehicle-Specific Requirements: Some vehicles may have unique requirements, such as specific gear selections or temperature ranges. Consult your vehicle’s service manual or technical information sources for these details.

- Safety Precautions: Always prioritize safety when performing a drive cycle. Be aware of your surroundings, maintain a safe following distance, and avoid distractions.

By understanding these challenges and implementing the appropriate strategies, you can increase your chances of successfully completing a drive cycle and getting your catalyst monitor ready. Remember, patience and persistence are key.

3. Diagnosing Common Issues with the Catalyst Monitor

If the catalyst monitor remains incomplete despite multiple drive cycle attempts, there may be underlying issues affecting its operation.

3.1. Using an OBDII Scanner

An OBDII scanner is a valuable tool for diagnosing catalyst monitor issues. It can provide information about:

- Diagnostic Trouble Codes (DTCs): Indicates specific problems affecting the vehicle’s systems.

- Monitor Status: Shows whether the catalyst monitor is ready or not ready.

- Live Data: Provides real-time sensor readings, which can help identify issues.

- Mode $06 Data: Displays the results of self-tests performed by the OBDII system.

3.2. Interpreting Diagnostic Trouble Codes (DTCs)

DTCs can provide valuable clues about why the catalyst monitor is not running. Here are some common DTCs related to the catalyst monitor:

- P0420: Catalyst System Efficiency Below Threshold (Bank 1)

- P0430: Catalyst System Efficiency Below Threshold (Bank 2)

- P0130-P0167: O2 Sensor Circuit Malfunction

- P0030-P0056: O2 Sensor Heater Circuit Malfunction

3.3. Common Sensor Issues

Faulty sensors can prevent the catalyst monitor from running. Here are some of the most common sensor-related problems:

- O2 Sensors: Malfunctioning O2 sensors can provide inaccurate readings, affecting the catalyst monitor’s ability to assess converter efficiency.

- Air/Fuel Ratio Sensors: Problems with air/fuel ratio sensors can also impact the catalyst monitor.

- Mass Airflow (MAF) Sensor: A faulty MAF sensor can cause incorrect air/fuel mixtures, affecting the catalyst monitor.

3.4. Other Potential Problems

In addition to sensor issues, other problems can affect the catalyst monitor:

- Exhaust Leaks: Leaks in the exhaust system can affect O2 sensor readings and prevent the catalyst monitor from running.

- Vacuum Leaks: Vacuum leaks can cause the engine to run lean, affecting the catalyst monitor.

- Engine Misfires: Misfires can damage the catalytic converter and prevent the monitor from running.

3.5. Using Mode $06 Data for Advanced Diagnostics

Mode $06 data provides detailed results of the self-tests performed by the OBDII system. It can help pinpoint specific issues affecting the catalyst monitor. While the raw data can be difficult to interpret, OEM scan tools provide decoded versions that are much more useful.

3.6. Steps for Diagnosing and Resolving Catalyst Monitor Issues

- Scan for DTCs: Use an OBDII scanner to check for any diagnostic trouble codes.

- Review Freeze Frame Data: Analyze the freeze frame data associated with any DTCs to understand the conditions when the code was set.

- Inspect Sensors: Check the O2 sensors, air/fuel ratio sensors, and MAF sensor for any signs of damage or malfunction.

- Check for Leaks: Inspect the exhaust and vacuum systems for any leaks.

- Monitor Live Data: Use an OBDII scanner to monitor live sensor data while the engine is running.

- Review Mode $06 Data: Analyze the Mode $06 data for the catalyst monitor to identify any failed tests.

3.7. How to Interpret Oxygen Sensor Readings

Oxygen sensors play a critical role in the catalyst monitor system, and understanding their readings is essential for effective diagnostics. Here’s how to interpret oxygen sensor readings:

- Voltage Range: Oxygen sensors typically operate within a voltage range of 0.1 to 0.9 volts.

- Low Voltage (0.1V): Indicates a lean condition (too much oxygen).

- High Voltage (0.9V): Indicates a rich condition (too little oxygen).

- Switching Frequency: A healthy oxygen sensor should switch rapidly between lean and rich conditions. Slow or erratic switching can indicate a failing sensor.

- Upstream vs. Downstream Sensors:

- Upstream Sensors (Before Catalytic Converter): These sensors measure the oxygen content of the exhaust gas before it enters the catalytic converter. Their readings should fluctuate rapidly.

- Downstream Sensors (After Catalytic Converter): These sensors measure the oxygen content after the catalytic converter. Their readings should be more stable, indicating the converter is effectively reducing pollutants.

- Interpreting Readings:

- Both Upstream and Downstream Sensors Switching: If both sensors are switching rapidly, it may indicate a problem with the catalytic converter’s efficiency.

- Downstream Sensor Mimicking Upstream Sensor: If the downstream sensor’s readings closely mirror the upstream sensor’s readings, it suggests the catalytic converter is not functioning correctly.

- No Activity from Either Sensor: If either sensor shows no activity or a flat line, it could indicate a sensor failure or a wiring issue.

- Using a Scan Tool: Many OBDII scan tools can display oxygen sensor data in real-time. This allows you to monitor the sensor readings while performing drive cycles or other diagnostic tests.

- Potential Issues: Common problems include:

- Delayed Response: Slow sensor response can indicate a degraded sensor.

- Sticking: A sensor that remains at a high or low voltage can indicate a sensor stuck in a rich or lean state.

- Contamination: Sensors can become contaminated with oil, coolant, or other substances, affecting their performance.

By carefully analyzing oxygen sensor readings, you can gain valuable insights into the health of the catalytic converter and the overall performance of the engine management system.

4. Professional Assistance and Services

If you’re struggling to get the catalyst monitor ready, consider seeking professional help.

4.1. When to Seek Professional Help

If you’ve tried multiple drive cycles, diagnosed and addressed potential issues, and the catalyst monitor still won’t run, it’s time to consult a professional.

4.2. Benefits of Professional Diagnostic Services

- Expertise: Experienced technicians have the knowledge and skills to diagnose complex issues.

- Specialized Tools: Professional shops have access to advanced diagnostic tools, such as OEM scan tools and exhaust gas analyzers.

- Comprehensive Testing: Technicians can perform thorough testing to identify underlying problems.

4.3. Finding a Reputable Repair Shop

- Check Reviews: Look for online reviews and testimonials.

- Ask for Recommendations: Seek recommendations from friends, family, or online communities.

- Verify Certifications: Ensure the shop employs certified technicians.

4.4. CARDIAGTECH.NET Services

At CARDIAGTECH.NET, we offer diagnostic and repair services to help you resolve catalyst monitor issues. Our team of experienced technicians uses state-of-the-art equipment to diagnose and fix problems efficiently.

5. Step-by-Step Guide: Running an OBDII Catalyst Monitor

Here’s a step-by-step guide to help you run the OBDII catalyst monitor:

5.1. Preparation

- Check for DTCs: Use an OBDII scanner to check for any diagnostic trouble codes (DTCs). Clear any existing codes, but note them down for future reference.

- Review Vehicle Information: Consult your vehicle’s service manual or a reliable online database (like those available through techinfo.toyota.com, techinfo.subaru.com, techinfo.honda.com, nissan-techinfo.com, and mazdaserviceinfo.com) to find the specific drive cycle for your vehicle.

- Gather Tools and Equipment: Ensure you have an OBDII scanner, a notepad, and a pen to record your progress.

- Plan Your Route: Identify a route that allows you to perform the drive cycle safely and without interruptions. Choose a time of day when traffic is minimal.

5.2. Initial Conditions

- Cold Start: Ensure the engine is cold. This typically means the engine hasn’t been run for at least eight hours.

- Fuel Level: Make sure your fuel tank is at least 1/4 full.

- No Electrical Loads: Turn off all unnecessary electrical loads such as headlights, air conditioning, and the radio.

5.3. Performing the Drive Cycle

- Start the Engine: Start the engine and let it idle for the specified time (usually 2-3 minutes). Do not touch the accelerator pedal during this time.

- Steady Cruise: Drive at a steady speed (e.g., 45-55 mph) for the specified duration (e.g., 5-10 minutes). Use cruise control to maintain a consistent speed.

- Deceleration: Decelerate smoothly without using the brake pedal. Allow the vehicle to coast down to a lower speed (e.g., 20 mph).

- Acceleration: Accelerate moderately back to the cruising speed.

- Repeat: Repeat the deceleration and acceleration steps several times as specified in the drive cycle.

- Idling: After completing the driving portion, let the vehicle idle for another 2-3 minutes.

5.4. Monitoring and Verification

- Connect OBDII Scanner: Connect your OBDII scanner and check the status of the catalyst monitor.

- Check Monitor Status: Look for the “Catalyst Monitor” status. It should indicate “Ready” or “Complete.”

- If Not Ready: If the monitor is not ready, repeat the drive cycle. It may take several attempts for the monitor to run, especially if there are underlying issues.

5.5. Troubleshooting

- Review DTCs: If the monitor still does not run after several attempts, check for new or recurring DTCs.

- Inspect Sensors: Check the oxygen sensors, MAF sensor, and other relevant sensors for any signs of damage or malfunction.

- Check for Leaks: Inspect the exhaust and vacuum systems for any leaks.

- Seek Professional Help: If you are unable to resolve the issue, consult a professional mechanic.

5.6. Example Drive Cycle for Toyota Vehicles

Here’s an example of a catalyst monitor drive cycle for a Toyota vehicle:

- Cold Start: Ensure the engine is cold (not run for at least 8 hours).

- Idle: Start the engine and let it idle for 2 minutes.

- Cruise: Drive at 50 mph for 8 minutes.

- Idle: Let the car idle for 1 minute.

- Cruise: Drive at 55 mph for 7 minutes.

- Idle: Idle for 2 minutes.

- Check Monitor Status: Connect the OBDII scanner and check the catalyst monitor status.

5.7. Tips for Success

- Patience: Drive cycles can be time-consuming and may require multiple attempts. Be patient and persistent.

- Consistency: Follow the instructions precisely and maintain consistent speeds and accelerations.

- Safety: Always prioritize safety when performing a drive cycle. Choose safe routes and avoid distractions.

- Documentation: Keep a record of your attempts and any DTCs or sensor readings you encounter.

6. Maximizing Catalyst Monitor Efficiency

To maximize the efficiency of your catalyst monitor and ensure it runs smoothly, consider these advanced tips and best practices:

6.1. Preemptive Maintenance

Regular maintenance can prevent issues that might hinder the catalyst monitor. Here’s a checklist:

- Scheduled Tune-Ups: Follow the manufacturer’s recommended service intervals for spark plugs, air filters, and other essential components.

- Oil Changes: Regular oil changes prevent engine wear and ensure optimal performance, which indirectly affects the catalyst monitor.

- Fuel System Cleaning: Use fuel system cleaners to remove deposits that can affect fuel efficiency and emissions.

6.2. Optimizing Fuel Quality

The quality of fuel you use can impact the catalyst monitor’s efficiency. Consider these points:

- Use Premium Fuel: Higher-octane fuels can improve combustion efficiency and reduce deposits.

- Avoid Ethanol Blends: Excessive ethanol can degrade fuel system components and affect sensor readings. Use ethanol-free fuel when possible.

- Fuel Additives: Use fuel additives that are designed to clean fuel injectors and maintain optimal fuel flow.

6.3. Monitoring and Logging Data

Advanced OBDII scanners can log data over time. Use this feature to:

- Record Drive Cycles: Log data during drive cycles to identify any deviations from the required parameters.

- Monitor Sensor Readings: Keep an eye on O2 sensor, MAF sensor, and other relevant sensor readings to detect potential issues early.

- Analyze Trends: Review logged data to identify trends that might indicate a problem with the catalytic converter or related systems.

6.4. Customizing Drive Cycles

In some cases, the standard drive cycle may not be effective. Consider these strategies:

- Adjust Parameters: Experiment with slight variations in speed and acceleration to find what works best for your vehicle.

- Extend Duration: Extend the duration of steady-state driving to allow the catalyst monitor more time to run.

- Combine Drive Cycles: Combine elements from different drive cycles to create a custom cycle that suits your vehicle’s specific needs.

6.5. Inspecting and Cleaning Components

Regularly inspect and clean key components to ensure they are functioning correctly:

- Oxygen Sensors: Remove and clean oxygen sensors to remove deposits that can affect their accuracy.

- MAF Sensor: Clean the MAF sensor using a specialized cleaner to ensure accurate airflow readings.

- Throttle Body: Clean the throttle body to remove carbon buildup that can affect idle and acceleration.

6.6. Addressing Underlying Issues

Even with the best maintenance practices, underlying issues can still prevent the catalyst monitor from running. Be prepared to:

- Diagnose and Repair: Address any DTCs or sensor readings that indicate a problem with the engine, exhaust, or fuel systems.

- Replace Faulty Parts: Replace any faulty sensors, valves, or other components that are affecting the catalyst monitor.

- Seek Professional Help: Consult a professional mechanic for complex issues that you cannot resolve on your own.

6.7. How to Check for Exhaust Leaks

Exhaust leaks can significantly impact the performance of the catalyst monitor and the accuracy of sensor readings. Here’s how to check for exhaust leaks:

- Visual Inspection:

- Examine the Exhaust System: Start by visually inspecting the entire exhaust system, from the exhaust manifold to the tailpipe. Look for signs of damage such as rust, cracks, holes, or loose connections.

- Check for Soot Deposits: Soot or black residue around joints, flanges, or welds can indicate a leak.

- Inspect Hangers and Mounts: Ensure that all exhaust hangers and mounts are in good condition and properly supporting the exhaust system.

- Auditory Inspection:

- Listen for Unusual Noises: With the engine running, listen for unusual hissing, tapping, or sputtering noises coming from the exhaust system.

- Cold Start: Exhaust leaks are often more noticeable during a cold start when the engine is still warming up.

- Soap and Water Test:

- Mix Soap and Water: Mix a solution of soap and water in a spray bottle.

- Spray the Exhaust System: With the engine running, spray the soap and water solution onto the joints, flanges, and welds of the exhaust system.

- Look for Bubbles: If there is a leak, the soap and water solution will bubble up.

- Smoke Test:

- Professional Smoke Test: A professional smoke test involves injecting smoke into the exhaust system and looking for smoke escaping from any leaks. This is a highly effective method for locating even small leaks.

- Hand Test:

- Feel for Leaks: With the engine running, carefully move your hand around the exhaust system to feel for escaping gases. Be cautious, as the exhaust system can be very hot.

- OBDII Scanner:

- Monitor Sensor Readings: Use an OBDII scanner to monitor oxygen sensor readings. Erratic or abnormal readings can indicate an exhaust leak.

- Addressing Leaks:

- Tighten Connections: If the leak is due to a loose connection, try tightening the bolts or clamps.

- Replace Gaskets: If the leak is due to a damaged gasket, replace it.

- Weld Repairs: For cracks or holes in the exhaust system, welding may be necessary.

- Professional Repair: If you are not comfortable performing exhaust system repairs, consult a professional mechanic.

7. Regulations and Compliance

Understanding the regulations and compliance requirements related to the OBDII catalyst monitor is crucial for vehicle owners and technicians alike.

7.1. Smog Check Requirements

Many states and regions require vehicles to pass regular smog checks to ensure they meet emission standards.

7.2. California Smog Check

In California, vehicles model year 2000 and newer are subject to OBDII-based smog checks. This involves checking the vehicle’s computer for any problems that might cause increased emissions.

7.3. Consequences of Failing a Smog Check

If your vehicle fails a smog check, you’ll need to address the issues and get it retested. Here are some potential consequences:

- Vehicle Registration Denial: You may not be able to renew your vehicle registration until it passes a smog check.

- Fines and Penalties: Some states may impose fines for driving a vehicle that doesn’t meet emission standards.

7.4. Legal Considerations for Catalyst Monitor Readiness

It’s important to be aware of the legal considerations related to catalyst monitor readiness. Here are some key points:

- Monitor Readiness Requirements: Most states require all OBDII monitors to be ready for a vehicle to pass a smog check.

- Exceptions: Some states may allow one or two monitors to be not ready, depending on the vehicle’s model year.

- Tampering with Emission Controls: It’s illegal to tamper with or disable any emission control devices, including the catalytic converter.

8. The Role of CARDIAGTECH.NET in OBDII Compliance

At CARDIAGTECH.NET, we are committed to helping vehicle owners and technicians achieve OBDII compliance. We offer a range of services and products to support this goal.

8.1. Diagnostic Tools and Equipment

We provide high-quality OBDII scanners and diagnostic tools to help you identify and resolve emission-related issues.

8.2. Repair Services

Our experienced technicians offer comprehensive repair services to address any problems affecting the catalyst monitor.

8.3. Educational Resources

We provide educational resources, including articles, guides, and videos, to help you understand OBDII systems and emission regulations.

8.4. Customer Support

Our customer support team is available to answer your questions and provide assistance with any OBDII-related issues.

9. Advanced Troubleshooting Techniques

9.1. Using Freeze Frame Data

Freeze frame data captures the engine’s operating conditions at the moment a DTC is set. This information can be invaluable for diagnosing intermittent issues that are difficult to reproduce.

9.2. Performing Component Tests

Component tests involve using an OBDII scanner to activate and test individual components, such as sensors, actuators, and valves.

9.3. Analyzing Waveforms

Advanced OBDII scanners can display sensor data as waveforms. Analyzing these waveforms can reveal subtle issues that might not be apparent from numerical data alone.

9.4. Checking Wiring and Connectors

Faulty wiring and connectors can cause a variety of OBDII-related issues. Carefully inspect all wiring and connectors for signs of damage, corrosion, or looseness.

9.5. Performing a Cylinder Compression Test

Low cylinder compression can cause engine misfires, which can affect the catalyst monitor. Perform a cylinder compression test to check the health of the engine’s cylinders.

10. Frequently Asked Questions (FAQ)

- What is an OBDII catalyst monitor?

- The OBDII catalyst monitor is a diagnostic test performed by a vehicle’s computer to assess the efficiency of the catalytic converter in reducing harmful emissions.

- Why is the catalyst monitor important?

- It ensures your vehicle meets emission standards, contributing to cleaner air and compliance with smog check requirements.

- How do I get the catalyst monitor ready?

- By performing a specific drive cycle that includes various driving conditions such as idling, steady cruising, acceleration, and deceleration.

- Where can I find the correct drive cycle for my vehicle?

- In the vehicle’s service manual, online technical information websites, or from CARDIAGTECH.NET as a customer.

- What are some common issues that can prevent the catalyst monitor from running?

- Recent battery disconnection, faulty sensors, drive cycle incompletion, exhaust leaks, vacuum leaks, and engine misfires.

- What is an OBDII scanner and how can it help diagnose catalyst monitor issues?

- An OBDII scanner is a diagnostic tool that can read diagnostic trouble codes (DTCs), monitor status, live data, and Mode $06 data to identify problems affecting the catalyst monitor.

- What should I do if the catalyst monitor is not ready after multiple drive cycle attempts?

- Check for DTCs, inspect sensors, check for leaks, monitor live data, and review Mode $06 data. If the issue persists, seek professional help.

- Can I pass a smog check with the catalyst monitor not ready?

- In many states, no. Most states require all OBDII monitors to be ready for a vehicle to pass a smog check, but there may be exceptions depending on the vehicle’s model year.

- What is Mode $06 data and how can it help diagnose catalyst monitor issues?

- Mode $06 data provides detailed results of self-tests performed by the OBDII system and can help pinpoint specific issues affecting the catalyst monitor.

- Why should I choose CARDIAGTECH.NET for help with my catalyst monitor issues?

- CARDIAGTECH.NET offers expert diagnostic and repair services, high-quality tools and equipment, educational resources, and dedicated customer support to help you achieve OBDII compliance.

11. Call to Action

Is your catalyst monitor giving you trouble? Don’t let emission issues hold you back. Contact CARDIAGTECH.NET today for expert diagnostic and repair services.

Address: 276 Reock St, City of Orange, NJ 07050, United States

WhatsApp: +1 (641) 206-8880

Website: CARDIAGTECH.NET

Let CARDIAGTECH.NET help you get your vehicle running smoothly and compliant with emission standards. Reach out now for a consultation and discover how our tools and expertise can make a difference for all of your automotive needs!