Interpreting Block 93 in VCDS is crucial for diagnosing and tuning your car’s engine timing. Are you struggling to understand the readings from VCDS Block 93 and optimize your engine’s performance? At CARDIAGTECH.NET, we provide expert guidance and tools to help you accurately interpret VCDS data and achieve optimal engine timing. Explore our selection of VCDS tools and diagnostic equipment to take control of your vehicle’s performance, including cam phase position, timing belt adjustment and engine diagnostic tools.

1. Understanding VCDS and Measuring Blocks

VCDS (VAG-COM Diagnostic System) is a software application used for diagnosing and troubleshooting Volkswagen Audi Group (VAG) vehicles. Measuring Blocks are specific data sets within VCDS that provide real-time information about various engine parameters.

1.1 What is VCDS?

VCDS, developed by Ross-Tech, is a comprehensive diagnostic tool for VAG vehicles, offering capabilities similar to those of a factory scan tool. It allows users to access and interpret data from various control modules within the vehicle, including the engine control unit (ECU), transmission control unit (TCU), and anti-lock braking system (ABS). VCDS is popular among automotive technicians and enthusiasts for its user-friendly interface and extensive functionality.

1.2 The Role of Measuring Blocks in Diagnostics

Measuring Blocks in VCDS display real-time data from sensors and components within the vehicle’s systems. These blocks provide valuable information for diagnosing issues, monitoring performance, and making adjustments. By examining the values in specific Measuring Blocks, technicians can identify deviations from expected ranges, pinpoint malfunctioning components, and assess the overall health of the vehicle.

For example, Measuring Blocks can show:

- Engine speed (RPM)

- Coolant temperature

- Throttle position

- Mass airflow

- Ignition timing

1.3 Accessing Measuring Blocks Using VCDS

To access Measuring Blocks in VCDS:

- Connect the VCDS interface cable to your vehicle’s OBD-II port and your computer.

- Launch the VCDS software on your computer.

- Select the control module you want to examine (e.g., Engine).

- Choose “Measuring Blocks” or “Advanced Measuring Values.”

- Enter the block number you want to view (e.g., 093 for Phase Position Bank 1).

- The software will then display the real-time data for the selected Measuring Block.

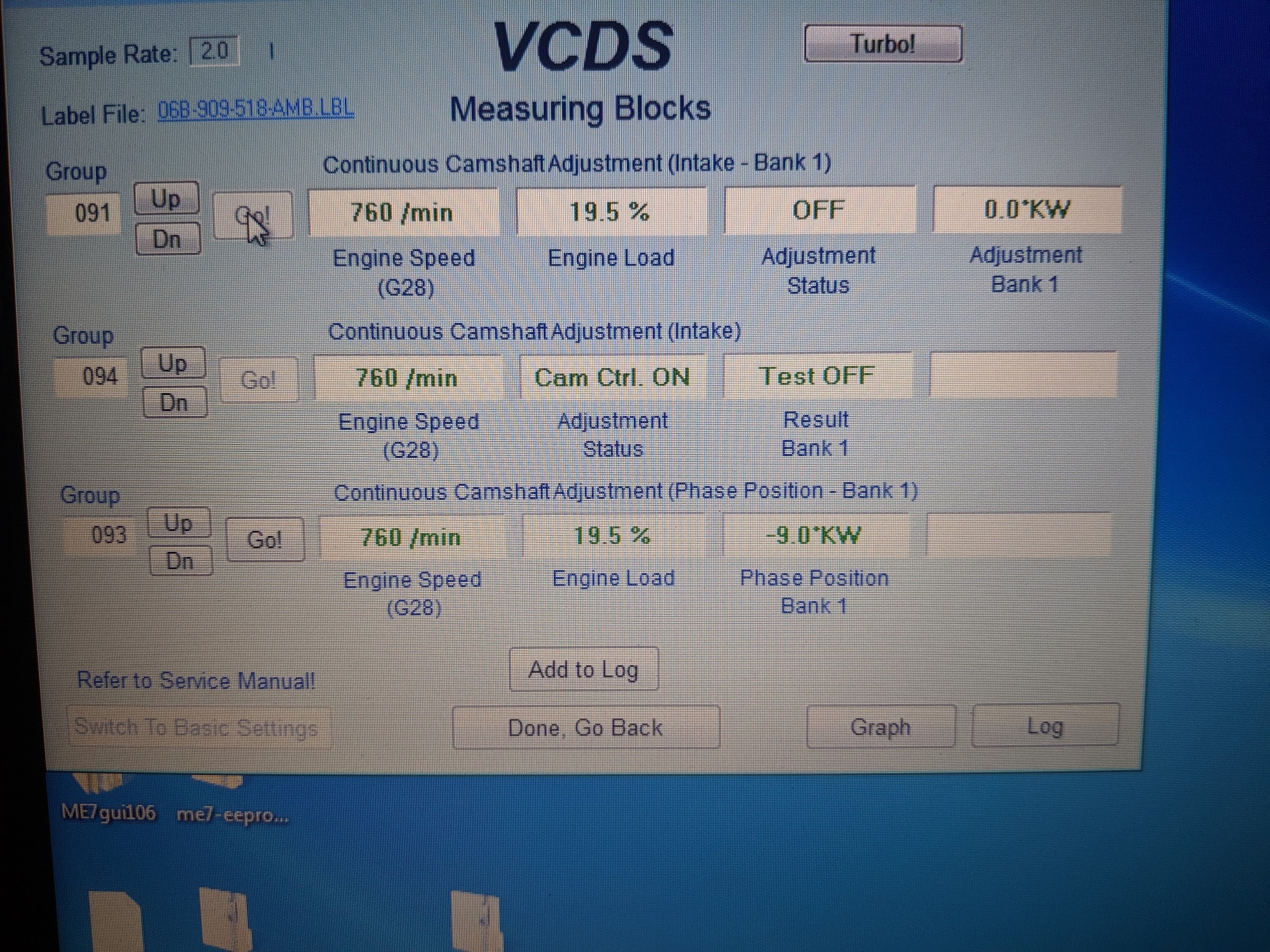

2. Decoding Block 93: Phase Position Bank 1

Block 93 in VCDS typically refers to the Phase Position Bank 1, which indicates the camshaft timing deviation from the specified value. Understanding this block is essential for diagnosing timing-related issues.

2.1 What Does Phase Position Bank 1 Indicate?

Phase Position Bank 1 provides information about the camshaft’s position relative to the crankshaft. This value is crucial for ensuring proper engine timing and optimal performance. A deviation from the specified value can indicate issues with the timing belt, chain, tensioner, or camshaft adjuster.

2.2 Common Units and Ranges in Block 93

The Phase Position Bank 1 value is typically displayed in degrees (°). The ideal range is usually around 0°, with a tolerance of +/- 6°. Values outside this range may indicate a timing issue.

| Parameter | Unit | Normal Range |

|---|---|---|

| Phase Position Bank 1 | Degrees | -6° to +6° |

2.3 Symptoms of Incorrect Phase Position

An incorrect Phase Position Bank 1 reading can manifest in various symptoms, including:

- Reduced engine performance: The engine may feel sluggish or underpowered.

- Poor fuel economy: Inefficient timing can lead to increased fuel consumption.

- Rough idling: The engine may vibrate or stall at idle.

- Check engine light: The ECU may trigger a fault code related to camshaft timing.

- Increased emissions: Improper timing can result in higher emissions levels.

3. Common Causes of Deviations in Block 93

Several factors can cause deviations in the Phase Position Bank 1 reading. Identifying the root cause is crucial for effective troubleshooting.

3.1 Timing Belt/Chain Issues

The timing belt or chain synchronizes the rotation of the crankshaft and camshaft(s). Wear, stretching, or improper installation can lead to timing deviations.

3.1.1 Wear and Tear

Over time, timing belts and chains can stretch or wear down, affecting the precision of valve timing. Regular inspection and replacement are essential to maintain optimal performance.

3.1.2 Improper Installation

Incorrect installation of the timing belt or chain can result in significant timing errors. It is crucial to follow the manufacturer’s instructions and use the correct tools for the job.

3.2 Camshaft Adjuster Problems

Many modern engines feature camshaft adjusters, also known as variable valve timing (VVT) systems, which optimize valve timing based on engine speed and load. Malfunctions in these systems can cause deviations in Block 93.

3.2.1 Solenoid Malfunctions

The camshaft adjuster is often controlled by a solenoid valve that regulates oil flow to the adjuster mechanism. A faulty solenoid can prevent the adjuster from functioning correctly.

3.2.2 Oil Pressure Issues

Proper oil pressure is essential for the camshaft adjuster to operate effectively. Low oil pressure due to a failing oil pump or clogged oil passages can impair the adjuster’s performance.

3.3 Sensor Failures

Crankshaft and camshaft position sensors provide crucial data to the ECU for calculating engine timing. Faulty sensors can lead to inaccurate readings and timing deviations.

3.3.1 Crankshaft Position Sensor

The crankshaft position sensor monitors the position and speed of the crankshaft. A failing sensor can cause erratic timing and misfires.

3.3.2 Camshaft Position Sensor

The camshaft position sensor monitors the position of the camshaft. A faulty sensor can result in incorrect valve timing and reduced engine performance.

4. Step-by-Step Guide to Interpreting Block 93

Interpreting Block 93 involves a systematic approach to identify and address potential timing issues.

4.1 Initial Assessment with VCDS

- Connect VCDS: Connect the VCDS interface cable to your vehicle and computer.

- Access Engine Control Module: Select the engine control module in VCDS.

- View Measuring Blocks: Go to “Measuring Blocks” and enter “093” to view Phase Position Bank 1.

- Record the Value: Note the value displayed for Phase Position Bank 1.

4.2 Analyzing the Readings

- Acceptable Range: If the value is within +/- 6°, the timing is likely within acceptable limits.

- Outside the Range: If the value is outside this range, further investigation is needed.

- Positive Deviation: A positive value indicates that the camshaft is advanced relative to the crankshaft.

- Negative Deviation: A negative value indicates that the camshaft is retarded relative to the crankshaft.

4.3 Performing Further Diagnostic Tests

If the Phase Position Bank 1 value is outside the acceptable range, perform the following diagnostic tests:

- Visual Inspection: Inspect the timing belt or chain for wear, damage, or improper alignment.

- Camshaft Adjuster Test: Use VCDS to activate the camshaft adjuster and monitor its response.

- Sensor Checks: Check the crankshaft and camshaft position sensors for proper function using a multimeter or oscilloscope.

4.4 Case Studies and Examples

Case Study 1: Timing Belt Misalignment

- Vehicle: 2010 Volkswagen Golf with a 2.0L TSI engine.

- Symptom: Check engine light, rough idling, and reduced performance.

- VCDS Reading: Block 93 showed a Phase Position Bank 1 value of -12°.

- Diagnosis: Visual inspection revealed that the timing belt was misaligned by one tooth.

- Resolution: Realigning the timing belt and replacing the tensioner corrected the timing issue, and the Block 93 value returned to 0°.

Case Study 2: Camshaft Adjuster Failure

- Vehicle: 2012 Audi A4 with a 2.0L TFSI engine.

- Symptom: Reduced engine power, poor fuel economy, and a check engine light.

- VCDS Reading: Block 93 showed a Phase Position Bank 1 value fluctuating between +8° and +10°.

- Diagnosis: Testing the camshaft adjuster with VCDS revealed that it was not responding correctly.

- Resolution: Replacing the camshaft adjuster solenoid resolved the issue, and the Block 93 value returned to the normal range.

5. Tools and Equipment for Timing Adjustments

Proper timing adjustments require specialized tools and equipment to ensure accuracy and prevent damage.

5.1 Essential Tools for Timing Belt/Chain Replacement

- Timing Belt/Chain Kit: Includes the belt or chain, tensioner, and idler pulleys.

- Camshaft Locking Tools: Used to hold the camshafts in the correct position during timing belt/chain replacement.

- Crankshaft Locking Tool: Used to lock the crankshaft in the top dead center (TDC) position.

- Tensioner Adjustment Tool: Used to properly tension the timing belt or chain.

5.2 VCDS and Diagnostic Scanners

VCDS: is essential for reading and interpreting engine data, including Block 93. It also allows you to perform various diagnostic tests and adaptations.

5.3 Multimeters and Oscilloscopes

- Multimeter: Used to check the electrical continuity and voltage of sensors and components.

- Oscilloscope: Used to analyze the waveforms of sensor signals for more in-depth diagnostics.

At CARDIAGTECH.NET, we offer a range of VCDS tools and diagnostic equipment to help you accurately diagnose and adjust engine timing. Our products are designed to meet the needs of both professional technicians and DIY enthusiasts.

6. Step-by-Step Timing Adjustment Procedure

Adjusting engine timing involves a series of steps to ensure proper synchronization between the crankshaft and camshaft(s).

6.1 Preparing for the Adjustment

- Gather Tools and Equipment: Collect all the necessary tools, including the timing belt/chain kit, camshaft locking tools, crankshaft locking tool, and tensioner adjustment tool.

- Disconnect Battery: Disconnect the negative terminal of the battery to prevent electrical shorts.

- Remove Accessories: Remove any accessories that may obstruct access to the timing belt or chain, such as the accessory drive belt and covers.

6.2 Setting the Engine to TDC

- Locate TDC Mark: Find the TDC mark on the crankshaft pulley or flywheel.

- Align the Mark: Rotate the crankshaft until the TDC mark aligns with the corresponding pointer or mark on the engine block.

- Insert Crankshaft Locking Tool: Insert the crankshaft locking tool to hold the crankshaft in the TDC position.

6.3 Installing the Timing Belt/Chain

- Align Camshaft Marks: Align the camshaft marks with the corresponding marks on the cylinder head or valve cover.

- Install Camshaft Locking Tools: Insert the camshaft locking tools to hold the camshafts in the correct position.

- Install Timing Belt/Chain: Install the timing belt or chain, ensuring that it is properly seated on all the pulleys and sprockets.

- Adjust Tensioner: Use the tensioner adjustment tool to properly tension the timing belt or chain according to the manufacturer’s specifications.

6.4 Verifying the Adjustment with VCDS

- Remove Locking Tools: Remove the camshaft and crankshaft locking tools.

- Rotate Engine Manually: Rotate the engine manually through at least two complete revolutions to ensure that there is no interference.

- Check Block 93: Connect VCDS and check the Phase Position Bank 1 value in Block 93.

- Fine-Tune if Necessary: If the value is still outside the acceptable range, repeat the adjustment procedure and fine-tune the timing as needed.

7. Advanced Diagnostic Techniques

For complex timing issues, advanced diagnostic techniques may be required to pinpoint the root cause.

7.1 Using an Oscilloscope to Analyze Sensor Signals

An oscilloscope can provide detailed information about the signals from the crankshaft and camshaft position sensors. By analyzing the waveforms, you can identify issues such as signal dropouts, noise, or incorrect timing patterns.

7.2 Performing a Compression Test

A compression test can help identify issues with valve timing or cylinder sealing. Low compression in one or more cylinders may indicate incorrect valve timing or valve damage.

7.3 Checking for Camshaft Wear

Excessive camshaft wear can affect valve timing and engine performance. Inspect the camshaft lobes for signs of wear, such as rounding or pitting.

8. When to Seek Professional Help

While many timing adjustments can be performed by experienced DIYers, certain situations warrant professional assistance.

8.1 Complex Engine Issues

If you are dealing with complex engine issues or are unsure about any aspect of the timing adjustment procedure, it is best to seek professional help.

8.2 Lack of Experience

If you lack experience in automotive repair, attempting a timing adjustment without proper knowledge and skills can lead to costly mistakes.

8.3 Specialized Tools and Equipment

Some timing adjustments require specialized tools and equipment that may not be readily available. In such cases, it is more efficient and cost-effective to hire a professional.

At CARDIAGTECH.NET, we understand the challenges of diagnosing and repairing modern vehicles. That’s why we offer a comprehensive range of VCDS tools, diagnostic equipment, and expert support to help you get the job done right. Whether you’re a professional technician or a DIY enthusiast, we have the tools and knowledge you need to succeed.

9. Benefits of Accurate Timing

Accurate engine timing is essential for optimal performance, fuel economy, and engine longevity.

9.1 Improved Engine Performance

Proper timing ensures that the valves open and close at the correct times, maximizing airflow and combustion efficiency.

9.2 Enhanced Fuel Efficiency

Accurate timing optimizes the combustion process, resulting in better fuel economy and reduced emissions.

9.3 Extended Engine Life

Correct timing reduces stress on engine components, extending the life of the engine and preventing premature wear.

10. Maintaining Optimal Timing

Maintaining optimal timing requires regular maintenance and inspection.

10.1 Regular Inspections

Inspect the timing belt or chain, tensioner, and camshaft adjuster at regular intervals to identify potential issues early on.

10.2 Timely Replacements

Replace the timing belt or chain, tensioner, and other related components according to the manufacturer’s recommended service intervals.

10.3 Proper Maintenance

Follow the manufacturer’s recommended maintenance schedule for oil changes, filter replacements, and other services to ensure optimal engine health.

By following these guidelines, you can ensure that your engine timing remains accurate and that your vehicle continues to perform at its best.

11. The Impact of Aftermarket Parts on Timing

Using aftermarket parts can sometimes affect engine timing and performance. It’s important to choose high-quality components and ensure they are compatible with your vehicle.

11.1 Choosing Quality Components

When replacing timing belts, chains, or adjusters, opt for reputable brands that meet or exceed OEM specifications.

11.2 Compatibility Issues

Ensure that any aftermarket parts you install are compatible with your vehicle’s engine and ECU. Incompatible parts can lead to timing deviations and other performance issues.

11.3 Calibration Requirements

Some aftermarket components may require calibration or adaptation using VCDS or other diagnostic tools. Follow the manufacturer’s instructions carefully to ensure proper installation and function.

12. Understanding Variable Valve Timing (VVT)

Variable Valve Timing (VVT) systems adjust the timing of the intake and/or exhaust valves to optimize engine performance and efficiency. Understanding how VVT works is crucial for diagnosing timing-related issues.

12.1 How VVT Systems Work

VVT systems use hydraulic or electric actuators to alter the camshaft’s position relative to the crankshaft. This allows the engine to optimize valve timing based on engine speed, load, and other factors.

12.2 Benefits of VVT

- Improved Fuel Economy: VVT optimizes combustion efficiency, resulting in better fuel economy.

- Increased Power Output: VVT can increase engine power and torque across a wide range of RPMs.

- Reduced Emissions: VVT helps reduce emissions by optimizing the combustion process.

12.3 Diagnosing VVT Issues

VVT issues can manifest as reduced engine performance, poor fuel economy, and a check engine light. Use VCDS to monitor VVT system parameters and perform diagnostic tests.

13. Common Mistakes to Avoid

When working on engine timing, it’s important to avoid common mistakes that can lead to serious engine damage.

13.1 Ignoring Warning Signs

Pay attention to any warning signs, such as unusual noises, vibrations, or performance issues. Ignoring these signs can lead to more significant problems down the road.

13.2 Using Incorrect Tools

Always use the correct tools for the job. Using incorrect tools can damage engine components and lead to improper timing adjustments.

13.3 Skipping Steps

Follow the timing adjustment procedure carefully, and don’t skip any steps. Skipping steps can result in incorrect timing and engine damage.

14. Real-World Examples of Timing Issues

Examining real-world examples can help you better understand how timing issues manifest and how to diagnose them effectively.

14.1 Example 1: Stretched Timing Chain

- Vehicle: 2008 Audi A3 with a 2.0L TFSI engine.

- Symptom: Check engine light, rattling noise from the engine, and reduced performance.

- VCDS Reading: Block 93 showed a Phase Position Bank 1 value of -15°.

- Diagnosis: Visual inspection revealed that the timing chain was stretched beyond its service limit.

- Resolution: Replacing the timing chain and tensioner corrected the timing issue, and the Block 93 value returned to 0°.

14.2 Example 2: Faulty Camshaft Position Sensor

- Vehicle: 2011 Volkswagen Jetta with a 2.5L engine.

- Symptom: Check engine light, rough idling, and occasional stalling.

- VCDS Reading: Block 93 showed a Phase Position Bank 1 value of +7°, but the reading was erratic.

- Diagnosis: Testing the camshaft position sensor revealed that it was faulty and producing an inconsistent signal.

- Resolution: Replacing the camshaft position sensor resolved the issue, and the Block 93 value stabilized within the normal range.

15. Resources for Further Learning

There are numerous resources available for further learning about engine timing and VCDS diagnostics.

15.1 Online Forums and Communities

Online forums and communities dedicated to VAG vehicles can provide valuable information, tips, and support.

15.2 Technical Manuals and Guides

Technical manuals and guides provide detailed information about engine timing, VCDS diagnostics, and repair procedures.

15.3 Training Courses and Workshops

Training courses and workshops offer hands-on experience and expert instruction in engine timing and VCDS diagnostics.

At CARDIAGTECH.NET, we are committed to providing our customers with the knowledge and resources they need to succeed. Our website features a wealth of information, including articles, guides, and videos, to help you master engine timing and VCDS diagnostics.

16. The Future of Automotive Diagnostics

Automotive diagnostics is constantly evolving, with new technologies and techniques emerging all the time.

16.1 Advancements in Diagnostic Tools

Diagnostic tools are becoming more sophisticated, with advanced features such as wireless connectivity, cloud-based data storage, and artificial intelligence.

16.2 Integration with Telematics Systems

Telematics systems are being integrated with diagnostic tools to provide real-time data and remote diagnostics capabilities.

16.3 Predictive Maintenance

Predictive maintenance techniques use data analytics to identify potential issues before they lead to breakdowns, reducing downtime and repair costs.

As automotive technology continues to advance, it’s important to stay up-to-date with the latest diagnostic tools and techniques. At CARDIAGTECH.NET, we are committed to providing our customers with the most advanced and innovative diagnostic solutions available.

17. Contact CARDIAGTECH.NET for Expert Support

If you need expert support with engine timing or VCDS diagnostics, don’t hesitate to contact CARDIAGTECH.NET.

17.1 Our Services

We offer a range of services, including:

- VCDS Tool Sales: We sell a variety of VCDS tools and diagnostic equipment to meet your needs.

- Technical Support: Our expert technicians provide technical support to help you diagnose and resolve issues.

- Training and Education: We offer training courses and workshops to help you master engine timing and VCDS diagnostics.

17.2 Contact Information

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- WhatsApp: +1 (641) 206-8880

- Website: CARDIAGTECH.NET

We are here to help you succeed. Contact us today to learn more about our products and services.

18. Optimizing Your Diagnostic Process

To make the most of your diagnostic efforts, it’s important to optimize your process and use the right tools and techniques.

18.1 Developing a Systematic Approach

Develop a systematic approach to diagnostics, starting with a thorough inspection and then using VCDS to gather data and perform tests.

18.2 Keeping Detailed Records

Keep detailed records of your diagnostic findings, including VCDS readings, test results, and repair procedures. This will help you track progress and identify patterns.

18.3 Staying Organized

Keep your tools and equipment organized to save time and reduce frustration. Use a tool box or cart to keep everything in its place.

19. The Importance of Regular Maintenance

Regular maintenance is essential for preventing timing-related issues and keeping your engine running smoothly.

19.1 Following the Maintenance Schedule

Follow the manufacturer’s recommended maintenance schedule for oil changes, filter replacements, and other services.

19.2 Inspecting Key Components

Inspect key components, such as the timing belt or chain, tensioner, and camshaft adjuster, at regular intervals.

19.3 Addressing Issues Promptly

Address any issues promptly to prevent them from escalating into more significant problems.

By following these guidelines, you can keep your engine in top condition and prevent timing-related issues.

20. Exploring Advanced VCDS Functions

VCDS offers a variety of advanced functions that can help you diagnose and troubleshoot complex issues.

20.1 Adaptation and Coding

VCDS allows you to perform adaptations and coding to adjust engine parameters and enable or disable features.

20.2 Output Tests

Output tests allow you to activate individual components, such as solenoids and actuators, to verify their function.

20.3 Data Logging

Data logging allows you to record real-time data from various sensors and components, which can be useful for identifying intermittent issues.

By exploring these advanced VCDS functions, you can gain a deeper understanding of your engine and its systems.

21. Staying Up-to-Date with VCDS Updates

VCDS is constantly being updated with new features, bug fixes, and vehicle support. It’s important to stay up-to-date with the latest updates to ensure that you have the most accurate and reliable diagnostic information.

21.1 Checking for Updates Regularly

Check for VCDS updates regularly on the Ross-Tech website or through the VCDS software.

21.2 Reading the Release Notes

Read the release notes for each update to learn about new features, bug fixes, and vehicle support.

21.3 Installing Updates Promptly

Install updates promptly to ensure that you have the latest and greatest version of VCDS.

22. Building a Diagnostic Knowledge Base

Building a diagnostic knowledge base can help you become a more efficient and effective technician.

22.1 Documenting Common Issues

Document common issues that you encounter, along with their symptoms, causes, and resolutions.

22.2 Creating Checklists and Procedures

Create checklists and procedures for common diagnostic tasks to ensure that you don’t miss any steps.

22.3 Sharing Knowledge with Others

Share your knowledge with others by participating in online forums, attending training courses, and mentoring junior technicians.

By building a diagnostic knowledge base, you can become a valuable resource for your colleagues and customers.

23. The Ethical Considerations of Automotive Diagnostics

As a technician, it’s important to adhere to ethical principles when performing automotive diagnostics.

23.1 Honesty and Integrity

Be honest and forthright with your customers about the issues you find and the repairs that are needed.

23.2 Transparency

Be transparent about your diagnostic procedures and the data you collect.

23.3 Respect for Privacy

Respect your customers’ privacy by protecting their personal information and not sharing it with others.

By adhering to ethical principles, you can build trust with your customers and maintain a positive reputation.

24. Legal Aspects of Automotive Diagnostics

There are legal aspects to consider when performing automotive diagnostics.

24.1 Warranty Issues

Be aware of warranty issues and ensure that any repairs you perform do not void the warranty.

24.2 Consumer Protection Laws

Be familiar with consumer protection laws and ensure that you are not violating any of these laws.

24.3 Environmental Regulations

Be aware of environmental regulations and ensure that you are not violating any of these regulations.

By understanding the legal aspects of automotive diagnostics, you can protect yourself and your customers.

25. Optimizing Your Workspace for Diagnostics

Optimizing your workspace can make diagnostics more efficient and enjoyable.

25.1 Ergonomics

Optimize your workspace for ergonomics to reduce strain and fatigue.

25.2 Lighting

Ensure that your workspace is well-lit to improve visibility.

25.3 Organization

Keep your workspace organized to save time and reduce frustration.

By optimizing your workspace, you can create a more comfortable and productive environment.

26. The Future of Engine Tuning with VCDS

Engine tuning with VCDS is becoming increasingly popular, allowing enthusiasts to optimize their engine’s performance and efficiency.

26.1 Customizing Engine Parameters

VCDS allows you to customize engine parameters, such as ignition timing, fuel injection, and boost pressure, to optimize performance.

26.2 Monitoring Performance Metrics

VCDS allows you to monitor performance metrics, such as horsepower, torque, and fuel economy, to assess the effectiveness of your tuning efforts.

26.3 Dangers of Improper Tuning

Improper tuning can lead to engine damage, so it’s important to proceed with caution and consult with experienced tuners.

Engine tuning with VCDS can be a rewarding experience, but it’s important to do your research and proceed with caution.

27. Purchasing Quality Diagnostic Tools from CARDIAGTECH.NET

Investing in quality diagnostic tools from CARDIAGTECH.NET is essential for accurate and reliable diagnostics.

27.1 Benefits of High-Quality Tools

High-quality tools are more accurate, durable, and reliable than cheap imitations.

27.2 Our Range of Products

We offer a range of diagnostic tools to meet your needs, from basic code readers to advanced VCDS systems.

27.3 Expert Support

Our expert technicians can help you choose the right tools for your needs and provide technical support to help you get the most out of your investment.

Investing in quality diagnostic tools from CARDIAGTECH.NET is an investment in your future.

28. How CARDIAGTECH.NET Can Help You Succeed

At CARDIAGTECH.NET, we are committed to helping you succeed.

28.1 Our Mission

Our mission is to provide our customers with the highest quality diagnostic tools, expert support, and valuable resources.

28.2 Our Values

Our values include honesty, integrity, transparency, and respect.

28.3 Our Commitment

We are committed to providing our customers with the best possible experience.

Contact CARDIAGTECH.NET today to learn more about how we can help you succeed.

29. FAQ: Interpreting Block 93 in VCDS

Here are some frequently asked questions about interpreting Block 93 in VCDS:

-

What does Block 93 in VCDS measure?

- Block 93 measures the Phase Position Bank 1, indicating the camshaft timing deviation from the specified value.

-

What is the acceptable range for Block 93 readings?

- The ideal range is usually around 0°, with a tolerance of +/- 6°.

-

What does a positive value in Block 93 indicate?

- A positive value indicates that the camshaft is advanced relative to the crankshaft.

-

What does a negative value in Block 93 indicate?

- A negative value indicates that the camshaft is retarded relative to the crankshaft.

-

What are some common causes of deviations in Block 93 readings?

- Common causes include timing belt/chain issues, camshaft adjuster problems, and sensor failures.

-

How can I check the timing belt/chain for wear?

- Visually inspect the timing belt/chain for wear, damage, or improper alignment.

-

What tools are needed for timing belt/chain replacement?

- Essential tools include a timing belt/chain kit, camshaft locking tools, a crankshaft locking tool, and a tensioner adjustment tool.

-

How can I test the camshaft adjuster with VCDS?

- Use VCDS to activate the camshaft adjuster and monitor its response.

-

What should I do if the Block 93 reading is outside the acceptable range?

- Perform further diagnostic tests, such as a visual inspection of the timing belt/chain and sensor checks.

-

When should I seek professional help for timing adjustments?

- Seek professional help if you are dealing with complex engine issues, lack experience, or require specialized tools and equipment.

30. Conclusion: Mastering VCDS Block 93 Interpretation

Mastering the interpretation of VCDS Block 93 is essential for diagnosing and resolving engine timing issues in VAG vehicles. By understanding the significance of Phase Position Bank 1, identifying potential causes of deviations, and following a systematic diagnostic approach, you can ensure optimal engine performance, fuel economy, and longevity. Remember to utilize the right tools and equipment, stay up-to-date with VCDS updates, and seek professional help when needed. With the resources and support available at CARDIAGTECH.NET, you can confidently tackle engine timing challenges and keep your vehicle running smoothly. Contact us today to explore our range of VCDS tools and diagnostic equipment and take control of your automotive diagnostics journey.

Camshaft position sensor

Camshaft position sensor

Image of a camshaft position sensor, crucial for accurate engine timing and diagnostics.

Facing timing issues? Don’t let incorrect readings hold you back. Contact CARDIAGTECH.NET at +1 (641) 206-8880 or visit CARDIAGTECH.NET for expert guidance and tools to resolve your engine timing challenges efficiently. Your engine’s optimal performance is just a call away.