The OBDII code P00C6, indicating “Fuel Rail Pressure Low during Engine Cranking,” might be an unfamiliar fault to many technicians. This article delves into a unique case study to shed light on this code, specifically observed in a 2012 Chevrolet Impala equipped with a 3.6L engine. This particular instance allowed for a practical demonstration of automotive theory in action, revealing the root cause of intermittent power loss reported by the vehicle owner. While the power issue seemed to diminish after extended driving, the underlying problem was pinpointed through careful diagnosis.

To effectively address the P00C6 code, a thorough understanding of the direct injection fuel system is crucial. Let’s begin with a system overview to grasp the operational mechanics at play.

Understanding the Direct Injection Fuel System

Direct injection systems necessitate high fuel pressure, which is supplied by a high-pressure fuel pump. In this Chevrolet Impala, the pump is strategically mounted at the rear of the engine and driven by a three-lobe cam on the bank 2 exhaust camshaft. This high-pressure pump not only delivers the required pressure but also regulates it via an internal solenoid-controlled valve.

For optimal engine performance across varying operating conditions, the Engine Control Module (ECM) dynamically requests fuel pressure between 2 to 15 MPa (290 to 2,176 psi), adjusting based on engine speed and load demands. The ECM employs output drivers to send a 12V Pulse Width Modulated (PWM) signal to the high-pressure fuel pump control circuit. This PWM signal precisely regulates fuel pressure by modulating the opening and closing of the control valve during pump strokes. This modulation dictates the portion of each pump stroke that ultimately reaches the fuel rail. Notably, in the absence of power to the control solenoid, the high-pressure fuel pump operates at its maximum flow capacity. As a safety measure, a relief valve within the high-pressure pump is designed to prevent pressure from exceeding 17.5 MPa (2,538 psi) in case of control failure.

Feedback for pressure regulation and injector control is provided by the fuel rail pressure sensor, a component diagnosed separately from the fuel pressure control system itself.

The ECM diligently monitors both the fuel rail fuel pressure sensor and the high-pressure fuel pump actuator. Its function is to ensure that the commanded and actual fuel pressures align within a predefined range, not only during engine cranking but also throughout all engine operating conditions. Furthermore, the ECM monitors the high-pressure fuel pump actuator’s operation to confirm it remains within expected operational limits.

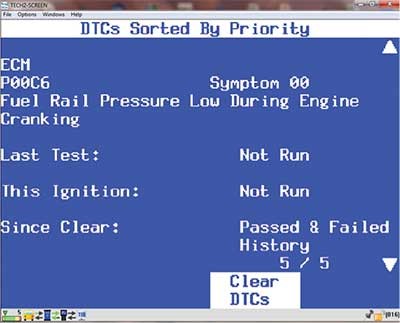

To illustrate the system’s behavior, we captured a series of snapshots using a Tech 2 scan tool, from engine startup to steady cruising. Figure 1 below clearly displays the P00C6 code that initiated this diagnostic journey. The subsequent figures (Figures 2-6) offer a detailed visual representation of the fuel system’s performance under different operating scenarios.

Figure 1

Initial Startup Fuel Pressure Analysis

Let’s examine the fuel pressure readings during the vehicle’s first start of the day. As shown in Figure 2, the low side pressure registered at 46 psi, while the high side pressure reached 585.8 psi. These readings provide a baseline for understanding the system’s initial state.

Figure 2

Fuel Pressure at Idle

Moving to idle conditions with the transmission in park, Figure 3 reveals the system’s adjustments for stable operation. The low side pressure stabilized at 43 psi, and the high side pressure settled at 391.5 psi at idle speed. This demonstrates the ECM’s control in modulating fuel pressure based on engine load.

Figure 3

Fuel Pressure During Cruise

To observe fuel pressure behavior under driving conditions, a road cruise test was conducted. With the transmission in Drive, the vehicle was driven to monitor pressure changes. Initially, as depicted in Figure 4, the low side pressure was 42 psi, and the high side pressure impressively reached 606.1 psi. This illustrates the high-pressure system’s capability to deliver substantial pressure during normal driving.

Figure 4

Anomalous Pressure Fluctuation

Subsequently, an unexpected event occurred. The low side pressure inexplicably surged to 73 psi, while the high side pressure dramatically decreased, converging to near equalization between both sides (68.2 psi vs. 70 psi as shown in Figure 5). This anomaly strongly suggested a malfunction in the high-pressure pump’s ability to maintain pressure differential, essentially indicating a non-functional high-pressure pump momentarily.

Figure 5

System Recovery and Pressure Normalization

Intriguingly, continued observation revealed a spontaneous recovery of the fuel system. Figure 6 captures this smooth return to normal operating pressures. The low side pressure decreased back to below 43 psi, and the high side pressure re-established its expected range, signifying the intermittent nature of the pump’s failure and its eventual, albeit temporary, self-correction.

Figure 6

Injector Leak-Down Test and Conclusion

To rule out potential injector leaks as a contributing factor, a leak-down test was performed. The system successfully passed this test, eliminating injectors as the source of the low fuel rail pressure. Based on the comprehensive diagnostic process and observed data, the definitive conclusion pointed to the high-pressure pump assembly as the culprit.

Consequently, the high-pressure pump was replaced. Following the replacement, the vehicle’s operation returned to its designed parameters, effectively resolving the P00C6 code and the associated power loss issue.

This case study underscores the importance of systematic diagnostics when addressing OBDII codes like P00C6. By meticulously analyzing system operation and utilizing scan tool data, even intermittent and elusive issues can be accurately diagnosed and effectively resolved, leading to successful automotive repairs. This Pulling Codes case is now closed, with a clear resolution achieved through diligent troubleshooting.