Experiencing difficulty starting your car, or perhaps it refuses to start altogether? Is your check engine light illuminated, displaying the error code P018C? This code points towards a potential issue with your fuel pressure sensor, often indicating low fuel pressure within the system. This article, brought to you by the automotive experts at autelfrance.com, will delve into the intricacies of the P018C error code, helping you understand, diagnose, and potentially resolve this issue.

Decoding the P018C Error Code

The P018C fault code is an EOBD/OBDII code officially defined as “Fuel Pressure Sensor ‘B’ Circuit Low”. This signifies that your vehicle’s Powertrain Control Module (PCM) is detecting an unusually low voltage signal from the fuel pressure sensor, specifically sensor “B”. Several factors can trigger this code, ranging from a malfunctioning sensor to actual low or excessively high fuel pressure within the system. It’s a common concern in modern vehicles equipped with sensors designed to constantly monitor fuel pressure for optimal engine performance. While the check engine light is a near-constant companion to this code, you may not immediately notice significant drivability problems in some instances.

During typical vehicle operation, the fuel pressure within the fuel rail fluctuates in response to varying engine demands. This fuel pressure sensor plays a crucial role by converting these pressure variations into electrical voltage signals, which are then relayed to the PCM. The PCM expects these signals to accurately reflect the real-time pressure changes within the fuel rail. The error code P018C is typically activated when the fuel pressure deviates significantly from the expected range, either too high or, as the code suggests, too low.

The PCM uses the information from the fuel pressure sensor to fine-tune the fuel delivery to the engine. By adjusting the pulse width of the fuel injectors, the PCM can increase or decrease the amount of fuel injected, thereby maintaining consistent fuel pressure and delivery.

When the PCM registers a consistently low voltage signal from the fuel pressure sensor “B” that doesn’t align with expected parameters, it interprets this as a malfunction within the fuel pressure sensor circuit. This discrepancy prompts the PCM to activate the check engine light and store the P018C error code in the vehicle’s computer system.

Recognising the Symptoms of a P018C Code

The presence of a check engine light and a stored OBD-II trouble code P018C are the primary indicators of this issue. However, depending on the severity and specific vehicle, you might encounter additional symptoms, including:

- Difficulty Starting or No-Start Condition: Insufficient fuel pressure makes it challenging for the engine to ignite and run. This can manifest as prolonged cranking before the engine starts, or the engine failing to start at all.

- Engine Stalling Immediately After Starting: In some cases, the fuel pump might be deactivated due to the detected low fuel pressure, causing the engine to stall shortly after ignition.

- Rough Idling, Stumbling, or Hesitation During Acceleration: Inconsistent fuel delivery due to low pressure can lead to erratic engine behaviour, noticeable as rough idling, stumbling upon acceleration, or hesitation when you press the accelerator pedal.

- Unpredictable and Frequent Engine Stalls: Low fuel pressure can cause intermittent fuel starvation, resulting in unexpected engine stalls, particularly at lower engine speeds or during deceleration.

- Intermittent Oxygen Sensor Related Codes: Fuel delivery issues can indirectly affect the air-fuel mixture, potentially triggering secondary oxygen sensor related error codes.

Pinpointing the Common Causes of the P018C Code

Several potential issues can lead to a P018C error code. A systematic approach to diagnosis is essential to accurately identify the root cause. The most common culprits include:

- Defective Fuel Pressure Sensor: The sensor itself might be faulty, providing inaccurate readings to the PCM even when the fuel pressure is within the normal range.

- Wiring Problems: Damaged, shorted, corroded, or disconnected wiring within the fuel pressure sensor circuit can disrupt the signal transmission, leading to a low voltage reading.

- Connector Issues: A faulty or corroded connector at the fuel pressure sensor or PCM can create resistance or signal loss, causing the P018C code to appear.

- Faulty Powertrain Control Module (PCM): Although less frequent, a malfunctioning PCM could misinterpret sensor signals or incorrectly diagnose a low fuel pressure condition.

- Improper Installation of Aftermarket Components: Incorrectly installed aftermarket parts or accessories, particularly those related to the fuel system or electrical system, can sometimes interfere with the fuel pressure sensor circuit.

Step-by-Step Diagnosis and Repair of the P018C Code

Diagnosing a P018C code effectively requires a methodical approach. Follow these steps to pinpoint the problem and implement the necessary repairs:

Step 1: Initial Wiring Inspection

Begin by carefully inspecting the wiring and connectors associated with the fuel pressure sensor “B”. Look for any signs of physical damage, such as frayed wires, corrosion, or loose connections. Pay close attention to areas where the wiring might rub against metal components, potentially causing a short circuit.

Step 2: Verifying Actual vs. Desired Fuel Pressure with a Scan Tool

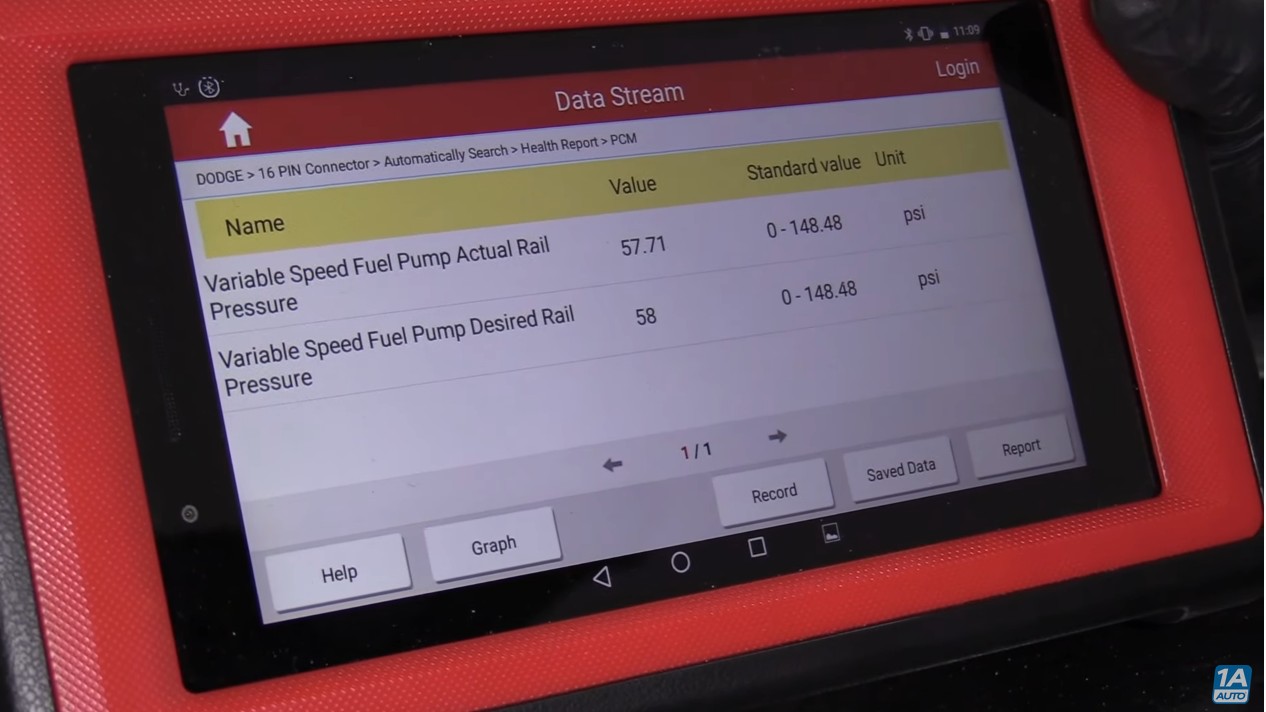

Connect an OBDII scan tool to your vehicle’s diagnostic port and navigate to the live data parameters. Locate the “Fuel Pressure Sensor” (FPS) data parameter. With the engine off, both the “desired” and “actual” fuel pressure readings should typically display default values, often near zero or atmospheric pressure.

Fuel pressure sensors are designed to output a higher voltage signal with increasing fuel pressure and a lower voltage signal when pressure decreases. Delays or inaccuracies in these signals can disrupt fuel delivery.

To assess sensor responsiveness, start the engine and observe the “actual” and “desired” fuel pressure readings on the scan tool. Compare the “actual” reading to the manufacturer’s specified fuel pressure range for your vehicle. If the deviation exceeds a couple of PSI (pounds per square inch), the fuel pressure sensor is likely faulty and requires replacement. A malfunctioning sensor often remains static at the default reading, failing to register pressure fluctuations. To further test the sensor, carefully disconnect and reconnect it while monitoring the FPS data parameter for changes. Important Safety Note: Always relieve pressure from the fuel system before disconnecting any fuel lines or sensors to prevent fuel spray and potential fire hazards.

If both “actual” and “desired” fuel pressure readings are consistently below the manufacturer’s specifications, the fuel pressure sensor itself might not be the primary issue. This scenario points towards a potential fuel delivery problem elsewhere in the system, such as a failing fuel pump or a blockage in the fuel lines. Further investigation of the fuel delivery system is then necessary.

Step 3: Testing for a Short Circuit

Another method to check for a faulty fuel pressure sensor involves disconnecting its electrical connector and turning the ignition key to the “ON” position (without starting the engine). Observe the OBDII scan tool for any changes in the error codes displayed. If disconnecting the sensor results in a change from P018C to a different code, such as P018D (Fuel Pressure Sensor “B” Circuit High), this strongly suggests a defective fuel pressure sensor. However, if the code remains P018C or no new code appears, it’s more likely that a short circuit exists within the wiring, possibly a wire grounding against a metal part of the vehicle.

Shop for Parts to Fix Code P018C and Low Fuel Pressure

[Link to relevant parts on 1AAuto.com]

In Summary

The OBDII error code P018C indicates a “Fuel Pressure Sensor ‘B’ Circuit Low” condition, often linked to low fuel pressure. By understanding the symptoms, common causes, and diagnostic procedures outlined in this guide, you can effectively troubleshoot and resolve this issue, restoring your vehicle’s optimal engine performance and fuel efficiency. Remember to consult your vehicle’s repair manual for specific procedures and fuel pressure specifications relevant to your make and model. For quality replacement parts to address P018C and fuel pressure related issues, visit autelfrance.com – your trusted source for automotive expertise and components.