For automotive technicians and car enthusiasts, understanding OBD-II error codes is crucial for effective vehicle diagnostics and repair. Among these codes, P00C6, indicating “Fuel Rail Pressure Low During Engine Cranking,” can be particularly challenging to diagnose. This error code points to potential issues within the direct injection fuel system, a critical component in modern vehicles. This article delves into the intricacies of the P00C6 code, exploring its causes, symptoms, and diagnostic procedures, enhanced with a real-world case study to provide practical insights.

Understanding OBD-II Code P00C6

The P00C6 diagnostic trouble code (DTC) is triggered when the Engine Control Module (ECM) detects that the fuel pressure in the fuel rail is lower than expected during engine cranking. Modern direct injection systems rely on high fuel pressure to ensure efficient combustion and optimal engine performance. This pressure is generated by a high-pressure fuel pump and meticulously regulated to meet the engine’s demands under various operating conditions. When the ECM senses a pressure drop below the specified threshold during the engine start-up phase, it sets the P00C6 code.

This code is significant because it directly relates to the fuel delivery system’s ability to provide adequate fuel pressure at a critical time – engine start. Without sufficient fuel pressure during cranking, the engine may experience difficulty starting, rough idling, or even fail to start altogether.

Symptoms of a P00C6 Error

While the P00C6 code itself is a strong indicator of a fuel pressure issue, several symptoms can further corroborate the diagnosis and aid in identifying the underlying problem:

- Hard Starting: The most common symptom. The engine may crank for an extended period before starting, or struggle to ignite.

- Engine Stalling: In some cases, especially in colder conditions or during initial start-up, the engine might stall shortly after starting due to insufficient fuel pressure.

- Lack of Power/Hesitation: If the low fuel pressure issue persists beyond cranking, it can lead to reduced engine power and hesitation during acceleration.

- Check Engine Light: The malfunction indicator lamp (MIL), or check engine light, will illuminate on the dashboard to alert the driver of a detected issue.

- Rough Idle: An unstable or rough idle can occur as the engine struggles to maintain consistent combustion with inadequate fuel pressure.

Potential Causes of P00C6

Several factors can contribute to a P00C6 error code. Pinpointing the exact cause requires systematic diagnosis, but common culprits include:

- Faulty High-Pressure Fuel Pump: The high-pressure fuel pump is the heart of the direct injection system. A failing pump may not be able to generate sufficient pressure, especially during the high demand cranking phase.

- High-Pressure Fuel Pump Regulator Issues: The fuel pump regulator controls the pressure output. A malfunctioning regulator could lead to insufficient pressure delivery.

- Fuel Rail Pressure Sensor Malfunction: An inaccurate fuel rail pressure sensor can provide incorrect readings to the ECM, leading to misdiagnosis and potentially triggering the P00C6 code even if the actual pressure is adequate.

- Fuel Leaks: Leaks in the high-pressure fuel lines or at injector seals can cause a pressure drop, especially during cranking when the system is building pressure.

- Restricted Fuel Filter: A clogged fuel filter can restrict fuel flow to the high-pressure pump, hindering its ability to build pressure effectively.

- Low-Pressure Fuel Supply Issues: Problems with the low-pressure fuel pump in the tank, or restrictions in the low-pressure fuel lines, can starve the high-pressure pump, leading to low rail pressure.

- ECM Issues: While less common, in rare instances, a fault within the ECM itself could lead to misinterpretation of sensor readings or incorrect fuel pump control.

Diagnosing P00C6: A Step-by-Step Approach

Diagnosing a P00C6 code requires a methodical approach. Here’s a general diagnostic procedure:

- Verify the Code: Use an OBD-II scanner to confirm the presence of the P00C6 code and check for any other related codes. Tools like the Autel MaxiSYS series or similar professional-grade scanners are ideal for this task.

- Check Low-Pressure Fuel System: Verify the operation of the in-tank fuel pump and check for any restrictions in the low-pressure fuel lines or fuel filter. Measure low-pressure fuel delivery to the high-pressure pump.

- Inspect for Fuel Leaks: Thoroughly inspect the high-pressure fuel lines, fuel rail, and injectors for any signs of fuel leaks. Be extremely cautious when working with high-pressure fuel systems.

- Monitor Fuel Rail Pressure: Use a scan tool to monitor the fuel rail pressure sensor readings during cranking and engine operation. Compare the actual pressure to the desired pressure specified by the manufacturer.

- High-Pressure Fuel Pump Test: Perform tests to evaluate the high-pressure fuel pump’s performance. This may involve checking pump output pressure and control signals. Some advanced scan tools offer specific high-pressure fuel pump tests.

- Fuel Rail Pressure Sensor Evaluation: Assess the accuracy of the fuel rail pressure sensor. Compare its readings with a known good sensor if possible.

- Injector Leakdown Test: Perform an injector leakdown test to rule out excessive injector leakage, which could contribute to low fuel rail pressure.

Real-World Case Study: 2012 Chevy Impala 3.6L and P00C6

To illustrate the diagnostic process, let’s examine a real-world case encountered with a 2012 Chevrolet Impala equipped with a 3.6L engine, mirroring the scenario from the original article. The vehicle presented with a P00C6 code and a customer complaint of intermittent power loss.

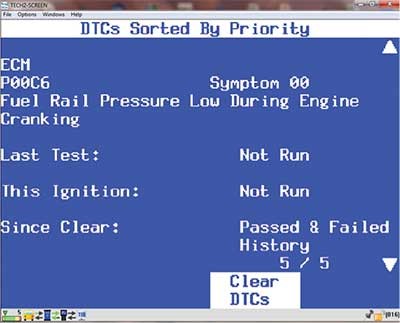

Initial inspection with a Tech 2 scan tool confirmed the P00C6 code. A quick system review highlighted the direct injection system’s operation, where a high-pressure fuel pump, driven by the exhaust camshaft, regulates fuel pressure based on ECM commands.

Figure 1: Display from a Tech 2 scan tool showing the P00C6 error code – Fuel Rail Pressure Low during Engine Cranking.

The diagnostic process began with monitoring fuel pressure during startup. Figure 2 shows the initial fuel pressure readings on a cold start.

Figure 2: Scan tool snapshot of fuel system parameters during initial engine start, displaying low side and high side fuel pressure readings.

As the engine stabilized at idle (Figure 3), fuel pressure adjusted accordingly.

Figure 3: Fuel pressure readings at idle, indicating stable low side pressure and adjusted high side pressure for idling conditions.

During a road test (Figure 4), the technician observed fluctuating fuel pressure readings. Initially, high-pressure readings were within expected parameters during cruising.

Figure 4: Fuel pressure readings captured during a vehicle cruise, showing expected high side pressure under load.

However, an anomaly was observed where the low-side pressure unexpectedly increased while the high-side pressure plummeted (Figure 5), indicating a potential high-pressure pump issue.

Figure 5: Scan tool display showing an unusual equalization of low and high side fuel pressures, suggesting a failing high-pressure fuel pump.

Remarkably, the system recovered spontaneously (Figure 6), with pressures returning to normal operating ranges, suggesting an intermittent fault within the high-pressure pump.

Figure 6: Fuel pressure readings indicating a smooth recovery back to normal operating parameters after the pressure anomaly.

An injector leakdown test was performed and passed, ruling out injector leakage. Based on these observations, the diagnosis pointed towards a failing high-pressure fuel pump assembly.

Resolving P00C6 and Maintaining Your Fuel System

In this case study, replacing the high-pressure fuel pump assembly resolved the P00C6 error and restored the vehicle’s performance. After replacement, the fuel system operated as designed, and the customer’s complaint of power loss was eliminated.

To prevent fuel system issues and potential P00C6 errors, regular maintenance is essential:

- Regular Fuel Filter Replacement: Adhere to the vehicle manufacturer’s recommended fuel filter replacement intervals to ensure clean fuel delivery.

- Quality Fuel: Use high-quality fuel from reputable sources to minimize contaminants that can clog the fuel system.

- System Inspections: Periodically inspect fuel lines and connections for leaks or damage.

- Prompt Diagnostics: Address any drivability issues or warning lights promptly to prevent minor problems from escalating into major repairs.

Conclusion

The P00C6 error code highlights a critical issue within the direct injection fuel system – low fuel rail pressure during engine cranking. Understanding the potential causes, symptoms, and diagnostic procedures is paramount for effective repair. As demonstrated in the case study, a systematic approach, coupled with the right diagnostic tools, can lead to accurate identification and resolution of P00C6 related problems, ensuring optimal vehicle performance and reliability. For automotive professionals and enthusiasts alike, mastering the diagnosis of codes like P00C6 is key to navigating the complexities of modern automotive technology.