Navigating the complexities of modern vehicle diagnostics can feel daunting, especially when the check engine light illuminates on your dashboard. Fortunately, the standardized On-Board Diagnostics II (OBDII) system provides a valuable tool for understanding your car’s health. This guide will delve into the world of OBDII codes, offering a comprehensive look at how to retrieve and interpret these diagnostic trouble codes, empowering you to take informed steps towards vehicle maintenance and repair.

What are OBD and OBDII Codes?

On-Board Diagnostics (OBD) systems were initially developed to monitor vehicle emissions. Over time, these systems evolved, becoming increasingly sophisticated and encompassing a wider range of vehicle functions. OBDII is the second generation of these systems and has been mandatory in most gasoline cars manufactured in the United States since 1996. It provides a standardized way to access vehicle subsystem information for diagnostics and repair.

OBDII codes, also known as diagnostic trouble codes (DTCs), are alphanumeric codes that your vehicle’s computer, the Engine Control Unit (ECU), generates when it detects a problem. These codes are designed to help mechanics and car owners identify potential issues, ranging from minor sensor malfunctions to more significant engine or transmission problems.

How to Retrieve OBD and OBDII Codes

While professional mechanics utilize sophisticated scan tools to read OBDII codes, there are methods you can employ to access these codes yourself, particularly useful for older vehicles. It’s important to note that these methods may not be as comprehensive as using a dedicated OBDII scanner, but they can provide a starting point for troubleshooting.

The “Key Trick” for Older (OBDI) Models

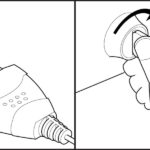

For vehicles predating the widespread adoption of OBDII, often referred to as OBDI models, a “key trick” can be used to retrieve diagnostic codes. This method involves turning the ignition key in a specific sequence to make the “check engine” light blink out the codes.

Procedure:

- Ensure the ignition is off.

- Within five seconds, cycle the key as follows: On, Off, On, Off, On. (Remember “On” is not “Start,” and “Off” is not “Lock”).

- Observe the “check engine” light. It will begin to flash.

- Count the flashes. Each code is a two-digit number. For example, code 23 would be indicated by two flashes, a pause, then three flashes (FLASH FLASH [pause] FLASH FLASH FLASH [long pause]).

- Be patient and watch for pauses, which separate the digits of a code and different codes from each other. A code 55, indicated by five flashes then five flashes, signifies the “end of codes” and is a normal output. Codes are generally not repeated.

Important Notes for OBDI Method:

- Setting the parking brake might be necessary for codes to display on some models.

- Blink spacing on older models might not be perfectly uniform, so pay close attention to the pauses.

- This method is designed for older, OBDI systems and may not work on newer OBDII vehicles.

The “Key Trick” for Newer (OBDII) Models

Some newer vehicles, particularly those around the transition to OBDII, may utilize a different “key trick” method, often displaying the codes on the digital odometer.

Procedure:

- Insert the key into the ignition.

- Press and hold the odometer reset button.

- While holding the button, turn the key to the “RUN” position (just before starting the engine).

- Release the odometer reset button.

- The odometer will typically cycle through a series of numbers (e.g., 111111 to 999999), then display the vehicle’s serial number.

- Following this, error codes may be displayed on the odometer, often prefixed with a “P” (e.g., Pxxxx).

Important Notes for OBDII Method:

- If this method fails to produce codes, try the OBDI “key trick” method as some vehicles may retain older diagnostic access methods.

- This method may not be universally applicable to all OBDII vehicles.

Understanding Older Model Computer Codes (OBDI)

It’s crucial to understand that OBDI codes are specific to older vehicle systems and may differ significantly from OBDII codes. The following list provides a comprehensive, though not exhaustive, compilation of OBDI codes commonly found in Chrysler vehicles of the era. Remember, these codes are aids for troubleshooting and not definitive repair guides.

Disclaimer: This list is compiled from various sources and may not be completely accurate or applicable to all vehicles. It is intended as a troubleshooting aid and not a repair manual. Consult a qualified mechanic for diagnosis and repair.

OBDI Codes List:

- 11: No ignition reference signal detected during cranking OR timing belt skipped one or more teeth; OR loss of either camshaft or crankshaft position sensor.

- 12: Battery or computer recently disconnected. (This code often appears after battery service and may clear itself).

- 13: MAP sensor or vacuum line may not be working. (Manifold Absolute Pressure sensor).

- 14: MAP sensor voltage below .16V or over 4.96V.

- 15: No speed/distance sensor signal. (Vehicle Speed Sensor).

- 16: Loss of battery voltage detected with engine running.

- 17: Engine stays cool too long (bad thermostat or coolant sensor?). OR 17 (1985 turbo only): knock sensor circuit.

- 21: Oxygen sensor signal doesn’t change (stays at 4.3-4.5V). Probably bad oxygen sensor.

- 22: Coolant sensor signal out of range – May have been disconnected to set timing. (Engine Coolant Temperature Sensor).

- 23: Incoming air temperature sensor may be bad. (Intake Air Temperature Sensor).

- 24: Throttle position sensor over 4.96V. (TPS).

- 25: Automatic Idle Speed (AIS) motor driver circuit shorted or target idle not reached.

- 26: Peak injector circuit voltage has not been reached (need to check computer signals, voltage regulator, injectors).

- 27: Injector circuit isn’t switching when it’s told to (TBI) OR (MPI) injector circuit #1 not switching right OR (turbo) injector circuit #2 not switching right OR (all 1990-) injector output driver not responding – check computer, connections.

- 31: Bad evaporator purge solenoid circuit or driver. (EVAP system).

- 32: (1984 only): power loss/limited lamp or circuit OR 32 EGR gases not working (1988): – check vacuum, valve OR 32 (1990-92): computer didn’t see change in air/’fuel ratio when EGR activated – check valve, vacuum lines, and EGR electrical. (Exhaust Gas Recirculation system).

- 33: Air conditioning clutch relay circuit open or shorted (may be in the wide-open-throttle cutoff circuit or normal on early 80’s models if you don’t have air conditioning).

- 34: (1984-86): EGR solenoid circuit shorted or open OR 34 (1987-1991): speed control shorted or open (cruise control).

- 35: Cooling fan relay circuit open or shorted OR 35: idle switch motor fault – check connections.

- 36 (turbo only): Wastegate control circuit open or shorted.

- 37: Shift indicator light failure, 5-speed OR part throttle lock/unlock solenoid driver circuit (87-89) OR solenoid coil circuit (85-87 Turbo only) OR Trans temperature sensor voltage low (1995 and on). (Transmission Temperature Sensor).

- 41: Alternator field control circuit open or shorted.

- 42: Automatic shutdown relay circuit open or shorted OR 42: Fuel pump relay control circuit OR 42: Fuel level unit – no change over miles OR 42: Z1 voltage missing when autoshutdown circuit energized (The Z1 voltage is the voltage of the circuits fed by the autoshutdown relay. This typically includes fuel pump and switched-battery feed to the ignition coil).

- 43: Peak primary coil current not achieved with max dwell time OR 43: Cylinder misfire OR 43: Problem in power module to logic module interface.

- 44: No FJ2 voltage present at logic board OR 44: Logic module self-diagnostics indicate problem OR 44: Battery temperature out of range.

- 45: Turbo boost limit exceeded (engine was shut down by logic module).

- 46: Battery voltage too high during charging or charging system voltage too low.

- 47: Battery voltage too low and alternator output too low.

- 51: Oxygen sensor stuck at lean position (this may be tripped by a bad MAP sensor system causing a rich condition. If you get hot rough idle and stalling, especially on deceleration, accompanied by flooded engine and difficulty restarting, that can be a bad MAP sensor causing the O2 sensor to try to compensate. If you get poor cold driveability, stumbling and bucking, and acceptable warm driving with poor gas mileage (a drop of 10 mpg or more), that is usually the O2 sensor. OR 51 Internal logic module fault (’84 turbo only).

- 52: Oxygen sensor stuck at rich position OR 52 Internal logic module fault (’84 turbo only).

- 53: Logic module internal problem.

- 54: No sync pickup signal during engine rotation (turbo only) OR 54 Internal logic module fault (’84 turbo only) – or camshaft sensor/distributor timing.

- 55: End of codes (Normal – not an error).

- 61: “Baro” sensor open or shorted. (Barometric Pressure Sensor).

- 62: EMR mileage cannot be stored in EEPROM.

- 62: PCM failure SRI mile not stored. (Powertrain Control Module, Service Reminder Indicator).

- 63: Controller cannot write to EEPROM. (Electrically Erasable Programmable Read-Only Memory).

- 64: Catalytic converter efficiency failure.

- 65: Power steering switch failure.

- 66: No CCD Message From TCM and/or No CCD Message From BCM. (Chrysler Collision Detection, Transmission Control Module, Body Control Module).

Understanding Newer Model Computer Codes (OBDII)

OBDII codes are more standardized across manufacturers and provide a more detailed and specific diagnosis compared to OBDI codes. OBDII codes are typically five characters long, starting with a letter followed by four numbers. The first letter indicates the system affected:

- P: Powertrain (Engine and Transmission)

- C: Chassis (Braking, Suspension, Steering)

- B: Body (Interior and Exterior, e.g., Airbags, Windows)

- U: Network/Communication (Communication between onboard computer systems)

The numbers provide further detail about the fault. While a full breakdown of OBDII code structure is beyond this guide, understanding the initial letter helps categorize the problem area.

Disclaimer: This list is compiled from various sources and may not be completely accurate or applicable to all vehicles. It is intended as a troubleshooting aid and not a repair manual. Consult a qualified mechanic for diagnosis and repair.

OBDII Codes List:

- 30: Sensor heater relay problem.

- 36: Sensor heater relay problem.

- 106: MAP sensor voltage out of range detected at startup.

- 107: MAP sensor voltage too low.

- 108: MAP sensor voltage too high.

- 112: Intake air temperature sensor voltage low.

- 113: Intake air (charge) temperature sensor voltage high.

- 116: Coolant temperature sensor reading doesn’t make sense.

- 117: Engine coolant temperature sensor voltage low.

- 118: Engine coolant temperature sensor voltage high.

- 121: Throttle position sensor and MAP sensor disagree with each other.

- 122: Throttle position sensor voltage low.

- 123: Throttle position sensor voltage high.

- 125: Taking too long to reach proper operating temperature and switch to energy-efficient mode.

- 130: Sensor heater relay problem.

- 130: O2 Sensor Circuit Malfunction (Bank 1 Sensor 1). (Oxygen Sensor).

- 131: O2 Sensor Circuit Low Voltage (Bank 1 Sensor 1).

- 132: O2 Sensor Circuit High Voltage (Bank 1 Sensor 1).

- 133: O2 Sensor Circuit Slow Response (Bank 1 Sensor 1).

- 134: O2 Sensor Circuit No Activity Detected (Bank 1 Sensor 1).

- 135: O2 Sensor Heater Circuit Malfunction (Bank 1 Sensor 1).

- 136: O2 Sensor Circuit Malfunction (Bank 1 Sensor 2).

- 137: O2 Sensor Circuit Low Voltage (Bank 1 Sensor 2).

- 138: O2 Sensor Circuit High Voltage (Bank 1 Sensor 2).

- 139: O2 Sensor Circuit Slow Response (Bank 1 Sensor 2).

- 140: O2 Sensor Circuit No Activity Detected (Bank 1 Sensor 2).

- 141: O2 Sensor Heater Circuit Malfunction (Bank 1 Sensor 2).

- 142: O2 Sensor Circuit Malfunction (Bank 1 Sensor 3).

- 143: O2 Sensor Circuit Low Voltage (Bank 1 Sensor 3).

- 144: O2 Sensor Circuit High Voltage (Bank 1 Sensor 3).

- 145: O2 Sensor Circuit Slow Response (Bank 1 Sensor 3).

- 146: O2 Sensor Circuit No Activity Detected (Bank 1 Sensor 3).

- 147: Oxygen sensor heater element not working properly (this device helps to reduce emissions more quickly).

- 151: Oxygen sensor voltage problem – short circuit to ground?

- 152: Oxygen sensor voltage problem – short circuit to active 12V?

- 153: Oxygen sensor response too slow.

- 154: Oxygen sensor does not show either a rich or lean condition – may need replacement.

- 155: Oxygen sensor heater element not working properly (this device helps to reduce emissions more quickly).

- 157: Oxygen sensor voltage problem – short circuit to ground?

- 158: Oxygen sensor voltage problem – short circuit to active 12V?

- 159: Oxygen sensor response too slow.

- 160: Oxygen sensor does not show either a rich or lean condition – may need replacement.

- 161: Oxygen sensor heater element not working properly (this device helps to reduce emissions more quickly).

- 171: The oxygen sensor is saying that the system air/fuel mix is far too lean (too much fuel is being added as a correction).

- 172: The oxygen sensor is saying that the system air/fuel mix is far too rich (too much air is being added as a correction).

- 174: The oxygen sensor is saying that the system air/fuel mix is far too lean (too much fuel is being added as a correction).

- 175: The oxygen sensor is saying that the system air/fuel mix is far too rich (too much air is being added as a correction).

- 176: Flex fuel sensor can’t be seen.

- 178: Flex fuel sensor problem.

- 179: Flex fuel sensor problem.

- 182: Compressed natural gas temperature sensor problem.

- 183: Compressed natural gas temperature sensor problem.

- 201: Injector #1 control circuit problem (open or shorted). (Fuel Injector).

- 202: Injector #2 control circuit problem (open or shorted).

- 203: Injector #3 control circuit problem (open or shorted).

- 204: Injector #4 control circuit problem (open or shorted).

- 205: Injector #5 control circuit problem (open or shorted).

- 206: Injector #6 control circuit problem (open or shorted).

- 207: Injector #7 control circuit problem (open or shorted).

- 208: Injector #8 control circuit problem (open or shorted).

- 300: Misfire detected in multiple cylinders.

- 301: Misfire detected in cylinder #1.

- 302: Misfire detected in cylinder #2.

- 303: Misfire detected in cylinder #3.

- 304: Misfire detected in cylinder #4.

- 305: Misfire detected in cylinder #5.

- 306: Misfire detected in cylinder #6.

- 307: Misfire detected in cylinder #7.

- 308: Misfire detected in cylinder #8.

- 320: Crankshaft position sensor reference signal cannot be found while the engine is cranking. (Crankshaft Position Sensor).

- 325: Knock sensor (#1) signal is wrong. (Knock Sensor).

- 330: Knock sensor (#2) signal is wrong.

- 340: No camshaft signal being received by the computer. (Camshaft Position Sensor).

- 350: A coil is drawing too much current. (Ignition Coil).

- 351: Coil #1 is not reaching peak current at the right time.

- 352: Coil #2 is not reaching peak current at the right time.

- 353: Coil #3 is not reaching peak current at the right time.

- 354: Coil #4 is not reaching peak current at the right time.

- 355: Coil #5 is not reaching peak current at the right time.

- 356: Coil #6 is not reaching peak current at the right time.

- 357: Coil #7 is not reaching peak current at the right time.

- 358: Coil #8 is not reaching peak current at the right time.

- 401: A required change in air/fuel mixture was not detected during diagnostic test.

- 403: An problem was detected in the EGR solenoid control circuit.

- 404: The EGR sensor’s reported position makes no sense.

- 405: EGR position sensor voltage wrong.

- 406: EGR position sensor voltage wrong.

- 412: The secondary air solenoid control circuit seems bad (this is used for the aspirator).

- 420: The catalyst seems inefficient (#1). (Catalytic Converter).

- 432: The catalyst seems inefficient (#2).

- 441: Evaporative purge flow system not working properly.

- 442: A leak has been detected in the evaporative system! (EVAP Leak – small).

- 443: Evaporative purge flow system solenoid not working properly.

- 455: A large leak has been detected in the evaporative system! (EVAP Leak – large).

- 456: A small leak has been detected in the evaporative system! (EVAP Leak – small).

- 460: The fuel level sender is not reporting any change over a long distance. Something seems wrong. (Fuel Level Sensor).

- 461: The fuel level sender is not reporting any change over a long time. Something seems wrong.

- 462: Fuel level sender voltage wrong.

- 463: Fuel level sender voltage wrong.

- 500: Haven’t heard from the speed sensor lately.

- 505: The idle speed air control motor doesn’t seem to be working correctly. (Idle Air Control Valve).

- 522: Oil pressure sensor problems. (Oil Pressure Sensor).

- 523: Oil pressure sensor problems.

- 551: The power steering switch may not be working. (Neons: high pressure is showing up at high speed). (Power Steering Pressure Switch).

- 600: Oh-oh! The coprocessors aren’t talking to each other within the computer! (ECU Internal Fault).

- 601: Internal computer error! (ECU Internal Fault).

- 604: Internal computer error! (RAM check). (ECU Internal Fault – RAM).

- 605: Internal computer error! (ROM). (ECU Internal Fault – ROM).

- 615: Starter relay circuit problem.

- 622: Generator field control problem. (Alternator Field Control).

- 645: A/C clutch relay circuit problem. (Air Conditioning Clutch Relay).

- 700: The automatic transmission computer or Aisin computer has a problem – ask it what’s going on. I don’t know. (Transmission System Fault).

- 703: Brake switch circuit information seems wrong. (Brake Switch).

- 711: Based on the transmission temperature and its operations, it looks like the transmission temperature sensor’s gone bad. (Transmission Temperature Sensor Fault).

- 712: Transmission fluid temperature sensor voltage wrong.

- 713: Transmission fluid temperature sensor voltage wrong.

- 720: The Output Shaft Speed Sensor doesn’t match the reported vehicle speed. (Output Shaft Speed Sensor).

- 740: The engine’s running faster than it should for these speeds, so I think the torque converter clutch lock-up system is bad. (Torque Converter Clutch Fault).

- 743: Torque converter clutch (part throttle unlock) solenoid circuit problem – shift solenoid C electrical fault.

- 748: Governor Pressure Solenoid circuit problem (Transmission relay circuit problem in Jeep RE transmissions). (Governor Pressure Solenoid).

- 751: Overdrive override switch has been pressed for over five minutes. Just thought you should know. (Overdrive Override Switch – informational, not necessarily an error).

- 753: Overdrive solenoid control circuit problem (transmission relay circuit in Jeep RE transmissions.). (Overdrive Solenoid).

- 756: Shift solenoid B (2-3) fault. (Shift Solenoid B).

- 783: The overdrive solenoid can’t go from 3rd gear to the overdrive gear. (Overdrive Solenoid Performance).

- 801: Transmission reverse gear lockout solenoid circuit problem! (Reverse Gear Lockout Solenoid).

- 833: Problem with the clutch-released switch circuit? (Clutch Switch – Manual Transmission).

- 1192: Inlet air temperature sensor voltage is wrong.

- 1193: Inlet air temperature sensor voltage is wrong.

- 1194: Oxygen sensor heater performance is faulty.

- 1195: Oxygen sensor is slow.

- 1196: The oxygen sensor switched too slowly (bank 2).

- 1197: The oxygen sensor switched too slowly (bank 1).

- 1198: Radiator coolant temperature sensor voltage is wrong.

- 1199: Radiator coolant temperature sensor voltage is wrong.

- 1281: The engine is staying cold too long – check your thermostat. (Thermostat Fault).

- 1282: The fuel pump relay circuit seems to be having a problem. (Fuel Pump Relay).

- 1288: The intake manifold short runner tuning valve circuit seems to be having a problem. (Intake Manifold Runner Control).

- 1289: There’s a problem in the manifold tuning valve solenoid control circuit.

- 1290: Compressed natural gas system pressure is too high.

- 1291: The heated air intake sensor does not seem to be working.

- 1292: Natural gas pressure sensor issue.

- 1293: Natural gas pressure sensor issue.

- 1294: Can’t get to target engine speed, check for vacuum leaks and idle speed motor issues.

- 1295: The throttle position sensor doesn’t seem to be getting enough electricity.

- 1296: The MAP sensor doesn’t seem to be getting enough electricity.

- 1297: The MAP sensor doesn’t change its reading when the engine is running!

- 1298: During wide-open throttle, the engine runs lean.

- 1299: MAP Sensor and Throttle Position Sensor signals don’t match, check for a vacuum leak.

- 1388: Auto shutdown relay circuit problems?

- 1389: No Z1 or Z2 voltage seen by the computer when the auto shutdown relay is used.

- 1390: Cam and crank signals don’t match – did the timing belt skip a tooth?

- 1391: Sometimes, I can’t see the crank or cam sensor signal.

- 1398: I can see the Crank Sensor’s signal when I prepare for Misfire Diagnostics. Try replacing it.

- 1399: Problem in the Wait to Start Lamp circuit – (diesels only?).

- 1403: EGR position sensor not getting (enough) voltage.

- 1476: Too little secondary air injection during aspirator test.

- 1477: Too much secondary air injection during aspirator test.

- 1478: Battery temperature sensor voltage wrong.

- 1479: Transmission fan relay circuit problems?

- 1480: PCV solenoid circuit problems? (Positive Crankcase Ventilation Solenoid).

- 1481: Transmission RPM pulse generator signal for misfire detection seems wrong.

- 1482: Catalyst temperature sensor circuit shorted low.

- 1483: Catalyst temperature sensor circuit shorted high.

- 1484: The catalyst seems to be overheating!

- 1485: Air injection solenoid circuit problems.

- 1486: Pinched or blocked hose in the evaporative hose system.

- 1487: Control circuit of the #2 high-speed radiator fan control relay is having problems.

- 1488: Auxiliary 5-volt sensor feed is too low.

- 1489: High speed radiator fan control circuit problem.

- 1490: Low speed radiator fan control circuit problem.

- 1491: Radiator fan control circuit problem (may be solid state relays as well as other circuits).

- 1492: Ambient or battery temperature sensor voltage wrong.

- 1493: Ambient or battery temperature sensor voltage wrong.

- 1494: Leak Detection Pump (LDP) pressure switch problem – electrical or the pump itself.

- 1495: Leak Detection Pump (LDP) pressure switch problem – the solenoid circuit.

- 1496: Sensor feed is below an acceptable limit. (under 4v for 4 seconds – should be 5v).

- 1498: High speed radiator fan control circuit problem. (#3 control relay)

- 1594: Voltage too high in charging system.

- 1595: Speed control vacuum or vent solenoid control circuits shorted or lost.

- 1596: Speed control switch always high.

- 1597: Speed control switch always low.

- 1598: A/C pressure sensor voltage high.

- 1599: A/C pressure sensor voltage low.

- 1681: No messages received from the cluster control module (dashboard computer).

- 1682: Charging system doesn’t seem to be working well. Check alternator, etc.

- 1683: Speed control servo power control circuit problem.

- 1684: The battery has been disconnected within the last 50 starts. (Informational – often appears after battery service).

- 1685: Invalid key received from the Smart Key Immobilizer Module.

- 1686: No messages received from the Smart Key Immobilizer Module.

- 1687: No messages received from the Mechanical Instrument Cluster module.

- 1693: The companion engine control module has shown a fault.

- 1694: No messages received from the powertrain control module-Aisin transmission.

- 1695: No messages received from the body control module.

- 1696: Unsuccessful attempt to write to an EEPROM location!

- 1697: Unsuccessful attempt to update Service Reminder Indicator (SRI or EMR) mileage!

- 1698: No messages received from the electronic transmission control module or the Aisin transmission controller.

- 1719: Transmission 2-3 gear lockout solenoid control circuit problem.

- 1740: Either the tcc solenoid or overdrive solenoid systems doesn’t seem to be making much sense.

- 1756: Transmission control pressure not equal to target. (Mid pressure problem).

- 1757: Transmission control pressure not equal to target. (Zero pressure problem).

- 1762: The Governor Pressure Sensor input was too high or too low for 3 consecutive park/neutral calibrations.

- 1763: The Governor Pressure Sensor input is too high.

- 1764: The Governor Pressure Sensor input is too low.

- 1765: Open or short in the Transmission Relay control circuit.

- 1899: The Park/Neutral switch seems to be stuck!

Using OBDII Codes for Diagnosis: Important Considerations

While retrieving OBDII codes using the “key trick” or a dedicated scanner can provide valuable insights, it’s crucial to remember that these codes are not a definitive diagnosis. They are indicators of potential issues, guiding you towards the system or component that might be malfunctioning.

Key Takeaways:

- OBDII codes are starting points: A code points to a potential problem area, but further investigation is usually needed to pinpoint the exact cause. For example, a code indicating an oxygen sensor issue might be due to a faulty sensor, wiring problems, or even a vacuum leak affecting the sensor’s readings.

- Context is crucial: Consider the symptoms your vehicle is exhibiting alongside the OBDII codes. Are you experiencing rough idling, poor fuel economy, or transmission shifting problems? These symptoms can provide valuable clues to narrow down the issue.

- Professional scan tools offer more data: While the “key trick” provides basic codes, professional OBDII scanners can access more detailed data from your vehicle’s computer, including freeze frame data (snapshots of sensor readings when the code was triggered) and live data streams, which are invaluable for accurate diagnosis.

- Disclaimer: This guide and the provided code lists are intended for informational purposes and as troubleshooting aids. They are not substitutes for professional automotive diagnostic procedures and repair manuals. Always consult a qualified mechanic for accurate diagnosis and repair of vehicle issues.

By understanding OBDII codes and how to retrieve them, you can become a more informed car owner, capable of communicating effectively with mechanics and making educated decisions about your vehicle’s maintenance. Remember to use these codes as a starting point and seek professional help for accurate diagnosis and repair to ensure your vehicle’s optimal performance and longevity.