Connecting to your vehicle’s On-Board Diagnostics II (OBDII) system using Carloop can sometimes present initial hurdles. This article outlines a streamlined approach to ensure successful OBDII data retrieval using Carloop, particularly for users working with platforms like Particle. Based on practical experience, we’ve identified key adjustments that can resolve common connectivity issues and establish reliable communication with your car’s CANbus network through Carloop Obdii.

Initially, accessing OBDII data via Carloop might seem challenging. However, by implementing a few crucial code modifications, as detailed below, robust data flow can be achieved. These steps are derived from hands-on testing and address typical pitfalls encountered when setting up Carloop for OBDII interaction.

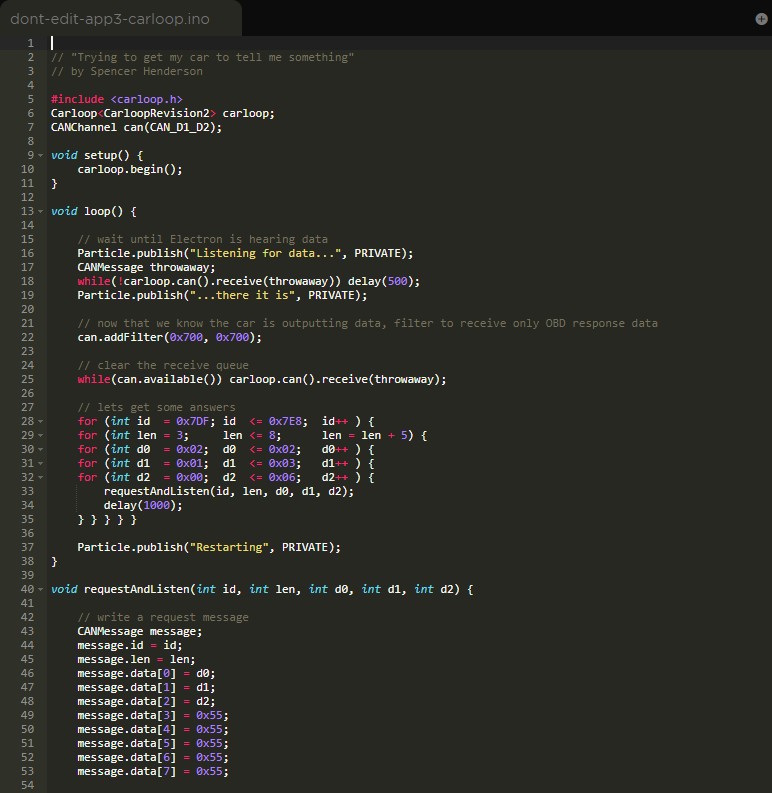

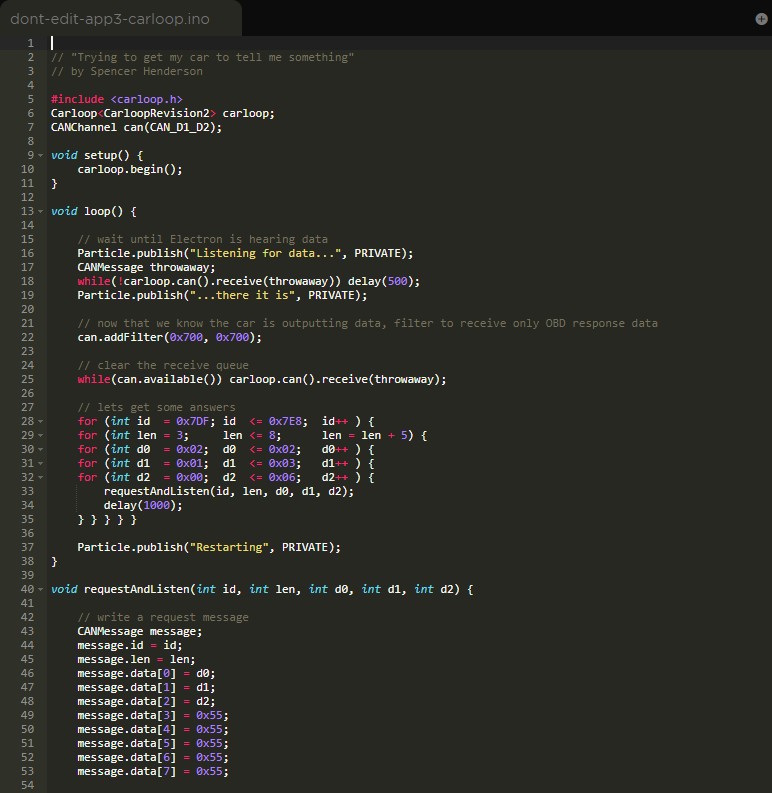

Here are the essential steps to configure your code for effective Carloop OBDII communication:

- Include Carloop Library: Begin by incorporating the Carloop library into your project. This is fundamental for leveraging Carloop’s functionalities.

- Add Header Inclusion: At the program’s beginning, insert

#include <Carloop.h>. This line ensures that the necessary Carloop library definitions are accessible throughout your code. - Declare Carloop Revision: Instantiate the Carloop object, specifying the Carloop revision being used. For instance, use

Carloop<carlooprevision2> carloop;to declare a Carloop object for revision 2. This step is crucial as it informs the microcontroller about the specific Carloop hardware in use, as recommended in Carloop example programs. - Initialize Carloop Begin: Replace the standard CAN bus initialization

can.begin(500000);withcarloop.begin();. Thecarloop.begin()command conveniently defaults to a 500000 bits/sec speed, aligning with common CANbus communication standards and simplifying setup. - Modify CAN Receive Calls: Update all instances of

can.receive(message)tocarloop.can().receive(message). This adjustment directs the CAN receive operations through the Carloop library interface. - Modify CAN Transmit Calls: Similarly, change all occurrences of

can.transmit(message)tocarloop.can().transmit(message). This ensures that CAN transmit commands are correctly routed via the Carloop library. - Ensure Sufficient Data Length in Messages: During testing, it was observed that setting message lengths to

message.len=8;facilitated successful responses from the CANbus, whereas shorter lengths likemessage.len=3;did not consistently yield responses. While the precise reason requires further investigation, padding the data field, for example by adding lines likemessage.data[3] = 0x55; message.data[4] = 0x55; message.data[5] = 0x55; message.data[6] = 0x55; message.data[7] = 0x55;, to ensure a length of 8 bytes might be necessary for reliable communication in some setups.

It’s important to note that while comprehensive testing is pending to pinpoint the exact cause of previous communication failures, initial findings suggest that the can.transmit() function’s interaction with Carloop might be a contributing factor. Adjusting the message length also appears to play a significant role in establishing a stable Carloop OBDII connection.

{width=772 height=793}By implementing these straightforward modifications, you can significantly enhance the reliability of your Carloop OBDII connection and ensure consistent data retrieval from your vehicle’s CANbus system. This refined approach provides a practical pathway for enthusiasts and professionals alike to effectively utilize Carloop for automotive diagnostics and data acquisition projects.