The Autel Ms906 Electric Shock can be a serious hazard for automotive technicians. CARDIAGTECH.NET provides solutions to prevent electrical shocks with proper usage and maintenance of your diagnostic tools. Learn how to avoid Autel MS906 electrocution, ensure safety protocols, and explore advanced diagnostic tools with CARDIAGTECH.NET to keep your shop safe and efficient.

1. Understanding the Risks of Electric Shock with Autel MS906

The Autel MaxiSYS MS906 Pro is a powerful tool, but like any electronic device, it presents a risk of electric shock if not handled correctly. Electric shocks can occur due to several factors, including damaged cables, exposure to moisture, or improper grounding. Understanding these risks is the first step in preventing accidents and ensuring a safe working environment. Addressing these risks immediately is critical to preventing unwanted accidents.

1.1 Common Causes of Electric Shock

Several factors can contribute to electric shocks when using the Autel MS906. Damaged insulation on cables can expose live wires, creating a direct path for electricity to flow through the user. Moisture can reduce the effectiveness of insulation and create conductive pathways, especially in damp environments. Improper grounding can also lead to electric shocks, as it prevents fault currents from safely dissipating. According to the Electrical Safety Foundation International (ESFI), a significant number of electrical injuries in the workplace are caused by these preventable factors.

1.2 Severity of Electric Shocks

The severity of an electric shock depends on several factors, including the amount of current, the path it takes through the body, and the duration of exposure. Mild shocks may cause tingling or muscle spasms, while more severe shocks can lead to burns, cardiac arrest, and even death. The National Safety Council (NSC) reports that even low-voltage shocks can be dangerous under certain conditions. Therefore, it is crucial to take all precautions to minimize the risk of electric shock.

Damaged cables leading to electric shock risk with Autel MS906

Damaged cables leading to electric shock risk with Autel MS906

2. Essential Safety Measures to Prevent Electric Shock

To prevent electric shocks when using the Autel MS906, it’s crucial to follow essential safety measures. These measures include inspecting equipment regularly, using personal protective equipment (PPE), ensuring proper grounding, and maintaining a dry working environment.

2.1 Regular Inspection of Equipment

Regularly inspect the Autel MS906 and its accessories for any signs of damage. Pay close attention to cables, connectors, and housing. Look for cracks, fraying, or exposed wires. Replace any damaged components immediately. According to the Occupational Safety and Health Administration (OSHA), regular equipment inspections are a fundamental part of workplace safety.

2.2 Using Personal Protective Equipment (PPE)

Always use appropriate personal protective equipment (PPE) when working with the Autel MS906. This includes insulated gloves, safety glasses, and non-conductive footwear. Insulated gloves can protect your hands from electric shock, while safety glasses shield your eyes from potential hazards. Non-conductive footwear prevents electricity from flowing through your body to the ground. OSHA mandates the use of PPE in hazardous environments to protect workers from injury.

2.3 Ensuring Proper Grounding

Proper grounding is essential for preventing electric shock. Ensure that the Autel MS906 and the vehicle under diagnosis are properly grounded. Grounding provides a safe path for fault currents to flow, reducing the risk of electric shock. Check grounding connections regularly to ensure they are secure and free from corrosion. The National Electrical Code (NEC) provides detailed guidelines for grounding electrical systems.

2.4 Maintaining a Dry Working Environment

Moisture increases the risk of electric shock. Keep your working environment dry and free from standing water. Avoid using the Autel MS906 in wet or damp conditions. If the device gets wet, dry it thoroughly before use. The Centers for Disease Control and Prevention (CDC) warns against using electrical devices in wet environments due to the increased risk of electrocution.

3. Best Practices for Using the Autel MS906 Safely

In addition to the essential safety measures, following best practices can further minimize the risk of electric shock when using the Autel MS906. These practices include proper training, following manufacturer guidelines, avoiding modifications, and disconnecting power sources when not in use.

3.1 Proper Training

Ensure that all technicians using the Autel MS906 receive proper training on its safe operation. Training should cover the risks of electric shock, safety measures, and best practices. Provide refresher training periodically to reinforce safety procedures. According to the National Institute for Occupational Safety and Health (NIOSH), comprehensive training programs are essential for preventing workplace injuries.

3.2 Following Manufacturer Guidelines

Always follow the manufacturer’s guidelines for using the Autel MS906. Read the user manual carefully and adhere to all safety instructions. The manufacturer provides specific recommendations for safe operation, maintenance, and troubleshooting. Ignoring these guidelines can increase the risk of electric shock.

3.3 Avoiding Modifications

Do not modify the Autel MS906 or its accessories. Modifications can compromise safety features and increase the risk of electric shock. Use only genuine Autel replacement parts and accessories. Unauthorized modifications can void the warranty and create hazardous conditions.

3.4 Disconnecting Power Sources When Not in Use

When the Autel MS906 is not in use, disconnect it from power sources. This prevents accidental activation and reduces the risk of electric shock. Store the device in a safe, dry place away from flammable materials. The U.S. Fire Administration recommends disconnecting electrical devices when not in use to prevent fires and electrical hazards.

4. Advanced Diagnostic Features and Safety

The Autel MaxiSYS MS906 Pro offers advanced diagnostic features designed to enhance vehicle maintenance and adaptability. These features, however, should be used with caution and adherence to safety protocols to prevent electrical hazards.

4.1 Online ECU Coding for Major Brands

The Autel MS906 Pro provides online ECU coding specifically for vehicles like BMW (F & E Chassis), Porsche, Volkswagen, Nissan, and Hyundai. This feature allows for precise and up-to-date coding directly from the manufacturer.

- Safety Protocol: Ensure stable internet connection and proper vehicle grounding. Incorrect coding can lead to electrical malfunctions, so verify all connections and settings before initiating.

4.2 Offline ECU Adaptation

This feature is perfect for brands such as Ford, Mazda, Jaguar, Vauxhall, and Opel, enabling modifications without an immediate internet connection.

- Safety Protocol: Double-check compatibility and settings. Incorrect adaptation can disrupt electrical systems. Use a reliable power source to prevent interruptions during the process.

4.3 Comprehensive Coding Capabilities

The Autel MS906 Pro allows you to modify OEM parameter settings, match, learn, or code new replaced ECUs, and change preprogrammed software options.

- Safety Protocol: Always back up existing data before making changes. Incorrect modifications can lead to system failures. Ensure all safety features like auto start/stop are properly configured to avoid electrical issues.

5. Comprehensive Coding Capabilities & Special Features

The Autel MS906 Pro offers comprehensive ECU coding options to maximize vehicle performance and adaptability. These features enable technicians to tailor vehicle systems to specific requirements or restore default settings. Matching, learning, or coding new replaced ECUs is essential for ensuring that new components are recognized and fully functional within the vehicle’s system. Technicians can also change preprogrammed software options to optimize vehicle settings that aren’t available through standard diagnostics, such as activating or deactivating features like auto start/stop. Customizing control settings such as flashing headlights and auto-folding mirrors enhances vehicle functionality and driver convenience.

5.1 Modifying OEM Parameter Settings

- Safety Protocol: Before modifying any OEM parameter settings, always back up the original settings. This ensures that you can revert to the original configuration if something goes wrong. Double-check all settings before applying them to the vehicle’s ECU.

5.2 Matching, Learning, or Coding New Replaced ECUs

- Safety Protocol: When matching, learning, or coding new ECUs, ensure that the replacement ECU is compatible with the vehicle. Use the correct coding procedures and verify that the ECU is functioning correctly after the coding process.

5.3 Changing Preprogrammed Software Options

- Safety Protocol: When changing preprogrammed software options, be aware of the potential impact on vehicle systems. Some changes may affect vehicle performance or safety. Always test the vehicle after making changes to ensure that everything is functioning as expected.

6. Responding to an Electric Shock Incident

Despite taking precautions, electric shock incidents can still occur. Knowing how to respond to an electric shock incident can save lives. The immediate steps to take include turning off the power source, providing first aid, and seeking medical attention.

6.1 Turning Off the Power Source

The first step in responding to an electric shock incident is to turn off the power source. If possible, switch off the circuit breaker or unplug the device. Do not touch the person in contact with the power source until the power is turned off. Using a non-conductive object, such as a wooden stick or a rubber mat, to separate the person from the power source if you cannot turn off the power immediately.

6.2 Providing First Aid

Once the power source is turned off, provide first aid to the person who has received the electric shock. Check for breathing and pulse. If the person is not breathing, administer CPR. If the person has a pulse but is not breathing, provide rescue breaths. Cover any burns with a clean, dry cloth. Keep the person warm and comfortable until medical help arrives. The American Red Cross provides comprehensive first aid training and resources.

6.3 Seeking Medical Attention

After providing first aid, seek medical attention for the person who has received the electric shock. Even if the person appears to be fine, internal injuries may not be immediately apparent. A medical professional can assess the person’s condition and provide appropriate treatment. Call emergency services immediately if the person is unconscious, has difficulty breathing, or has severe burns.

7. Advanced Troubleshooting Techniques

The Autel MaxiSYS MS906 Pro is a cutting-edge diagnostic tool designed for comprehensive vehicle diagnostics and maintenance. It runs on Android 7 and features an 8-inch high-resolution touchscreen, a robust Samsung Exynos Octa-core processor, and 128 GB of storage. It has a long-lasting 11,600 mAh battery and high-quality cameras for documentation and scanning. It connects vehicles using the advanced MaxiCVI V200 interface, supporting the latest protocols such as CANFD.

7.1 Diagnostic Features & Comprehensive Coverage

-

Extensive Coverage: The MS906 Pro supports diagnostics for all systems in vehicles manufactured after 1996, covering over 80 OEMs. It includes AutoVIN/Scan VIN features for quick vehicle identification.

-

Continuous Updates: It offers two years of free software updates and a one-year warranty, ensuring that your diagnostic tools remain current with technological advancements and new vehicle models.

-

Fault Diagnosis: Rapidly read and clear diagnostic trouble codes. Effectively manage system alerts for airbags, ABS, and engine lights to maintain vehicle safety.

-

Live Data: Access real-time sensor and system data for accurate diagnosis and efficient troubleshooting.

-

Freeze Frame Data: Capture and analyze the exact vehicle condition at the time of a fault.

-

Customizable Reports: Generate pre and post-scan reports that can be easily customized and emailed directly to clients for enhanced service transparency.

7.2 Service Functions

The MS906 Pro supports over 30 service functions, enabling technicians to handle a wide range of maintenance tasks efficiently:

-

Oil Reset: Reset the oil service calculator in engines and automatic transmissions.

-

EPB: Adjust and reset electronic parking brakes.

-

TPMS: Monitor and configure tire pressure.

-

BMS: Register and reset vehicle battery systems.

-

Injector Coding: Program new injector numbers into the vehicle’s ECU after replacement.

-

SAS: Calibrate steering angle sensors after repair or alignment.

-

DPF: Manage diesel particulate filter systems.

-

IMMO Keys: Program new keys.

-

ABS/SRS: Diagnose and clear faults in anti-lock braking and airbag systems.

-

Throttle Relearn: Optimize throttle response.

-

Brake Bleed: Perform bleeding of the brake system.

-

Headlamp: Adjust headlamp settings.

7.3 Active Tests (Bi-Directional Control)

The MS906 Pro can command the vehicle’s ECUs to perform specific functions to verify system integrity. Examples include:

-

Component Testing: Fuel pump activation, solenoid and relay testing.

-

Operational Checks: Ensure windows, doors, and sunroofs operate correctly.

-

Real-Time Monitoring: Confirm adjustments are effective immediately.

8. Implementing a Safety Program in Your Workshop

Implementing a comprehensive safety program in your workshop is essential for preventing electric shock and other workplace hazards. A safety program should include regular safety meetings, hazard assessments, and emergency response plans.

8.1 Regular Safety Meetings

Conduct regular safety meetings to discuss safety issues, review safety procedures, and provide safety training. Safety meetings should be held at least monthly and should involve all employees. Use safety meetings to address specific hazards and to reinforce the importance of safety. The National Safety Council (NSC) offers resources and training materials for conducting effective safety meetings.

8.2 Hazard Assessments

Conduct regular hazard assessments to identify potential hazards in the workplace. A hazard assessment involves inspecting the workplace, identifying potential hazards, and evaluating the risk of each hazard. Use the hazard assessment to develop control measures to eliminate or reduce the risk of each hazard. OSHA provides guidelines for conducting hazard assessments.

8.3 Emergency Response Plans

Develop emergency response plans for responding to electric shock incidents and other workplace emergencies. An emergency response plan should include procedures for reporting emergencies, evacuating the workplace, and providing first aid. Ensure that all employees are familiar with the emergency response plan and know what to do in an emergency. The Federal Emergency Management Agency (FEMA) provides resources and guidance for developing emergency response plans.

9. Staying Updated on Safety Standards and Regulations

Staying updated on safety standards and regulations is essential for maintaining a safe working environment. Safety standards and regulations are constantly evolving, and it is important to stay informed about the latest changes.

9.1 OSHA Standards

The Occupational Safety and Health Administration (OSHA) sets and enforces safety standards for the workplace. OSHA standards cover a wide range of hazards, including electrical safety, machine guarding, and personal protective equipment. Stay informed about OSHA standards and ensure that your workplace complies with all applicable requirements. OSHA provides resources and training materials to help employers comply with safety standards.

9.2 National Electrical Code (NEC)

The National Electrical Code (NEC) provides guidelines for the safe installation and maintenance of electrical systems. The NEC is updated every three years and reflects the latest advances in electrical safety. Stay informed about the NEC and ensure that your electrical systems comply with all applicable requirements. The National Fire Protection Association (NFPA) publishes the NEC and provides training and resources for electrical safety.

9.3 Industry Best Practices

In addition to OSHA standards and the NEC, stay informed about industry best practices for electrical safety. Industry associations and professional organizations often publish guidelines and recommendations for safe work practices. These best practices can help you go beyond the minimum requirements of safety standards and create a safer working environment.

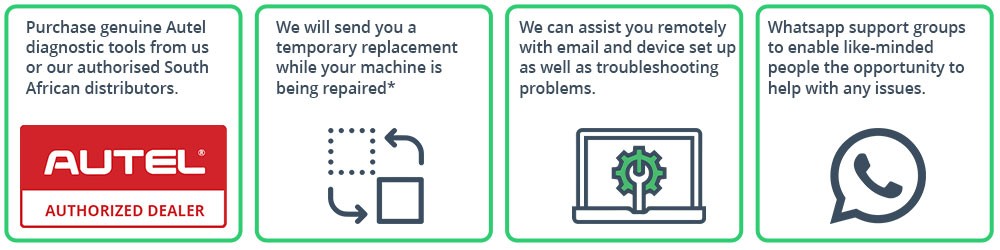

10. CARDIAGTECH.NET Solutions for Automotive Technicians

CARDIAGTECH.NET offers a range of solutions to help automotive technicians work safely and efficiently. These solutions include high-quality diagnostic tools, safety equipment, and training programs.

10.1 High-Quality Diagnostic Tools

CARDIAGTECH.NET provides high-quality diagnostic tools like the Autel MaxiSYS MS906 Pro, designed for comprehensive vehicle diagnostics and maintenance. These tools are built to meet the highest safety standards and provide accurate and reliable results. Investing in high-quality diagnostic tools can reduce the risk of errors and improve the efficiency of your work.

10.2 Safety Equipment

CARDIAGTECH.NET offers a range of safety equipment, including insulated gloves, safety glasses, and non-conductive footwear. This equipment is designed to protect technicians from electric shock and other workplace hazards. Providing your technicians with the right safety equipment can help prevent injuries and create a safer working environment.

10.3 Training Programs

CARDIAGTECH.NET offers comprehensive training programs on the safe operation of diagnostic tools and equipment. These training programs cover the risks of electric shock, safety measures, and best practices. Providing your technicians with proper training can help them work safely and efficiently.

11. Importance of Regular Maintenance and Calibration

Maintaining your Autel MS906 Pro is critical for both its performance and safety. Regular maintenance and calibration can prevent malfunctions that could lead to inaccurate readings or electrical issues.

11.1 Scheduled Inspections

Implement a schedule for inspecting your diagnostic tools. Look for any signs of wear, damage, or corrosion. Pay special attention to cables, connectors, and the device’s housing.

11.2 Calibration Services

Ensure your Autel MS906 Pro is calibrated regularly. Calibration ensures that the tool provides accurate readings. Contact CARDIAGTECH.NET for calibration services to maintain the integrity of your diagnostic equipment.

11.3 Software Updates

Keep your Autel MS906 Pro software updated. Software updates often include improvements to safety features and performance enhancements. Regularly check for updates and install them promptly.

12. Advanced Diagnostic Capabilities: Maximizing Efficiency with Safety

The Autel MaxiSYS MS906 Pro is engineered to provide extensive diagnostic capabilities, enabling technicians to handle complex automotive issues efficiently while maintaining the highest safety standards.

12.1 Broad Vehicle Coverage

The Autel MS906 Pro supports a wide range of vehicle manufacturers and models, ensuring comprehensive diagnostic coverage. This broad compatibility allows technicians to work on various vehicles without needing multiple tools, enhancing efficiency.

12.2 User-Friendly Interface

The intuitive user interface of the Autel MS906 Pro makes it easy to navigate through diagnostic procedures. Technicians can quickly access the necessary functions and data, reducing diagnostic time and improving overall productivity.

12.3 Wireless Connectivity

With wireless connectivity, the Autel MS906 Pro allows technicians to move freely around the vehicle while performing diagnostics. This flexibility enhances convenience and reduces the risk of accidents caused by tangled cables.

13. Practical Steps to Ensure Safety with Diagnostic Tools

To minimize the risk of electric shock and ensure safe operation, follow these practical steps when using diagnostic tools like the Autel MS906 Pro.

13.1 Pre-Use Inspection

Before each use, inspect the diagnostic tool for any signs of damage. Check cables for fraying, connectors for looseness, and the device housing for cracks or breaks. Do not use the tool if any damage is found.

13.2 Proper Grounding

Ensure that the vehicle and the diagnostic tool are properly grounded before starting any diagnostic procedures. Proper grounding helps to prevent electrical shock by providing a safe path for electrical current in case of a fault.

13.3 Dry Environment

Operate the diagnostic tool in a dry environment. Avoid using the tool in wet or damp conditions, as moisture can increase the risk of electric shock.

13.4 Insulated Tools

Use insulated tools when working with electrical components. Insulated tools provide an extra layer of protection against electric shock.

13.5 Personal Protective Equipment (PPE)

Wear appropriate PPE, such as safety glasses and insulated gloves, when using diagnostic tools. PPE helps to protect against potential hazards, including electric shock.

14. How to Select the Right Diagnostic Tools for Your Needs

Choosing the right diagnostic tools is essential for ensuring both efficiency and safety in automotive repair. Here are some factors to consider when selecting diagnostic tools:

14.1 Compatibility

Ensure that the diagnostic tool is compatible with the types of vehicles you work on. Check the tool’s specifications to see which makes and models it supports.

14.2 Features

Consider the features you need in a diagnostic tool. Some tools offer advanced features such as ECU coding, bi-directional control, and live data streaming. Choose a tool with the features that will best meet your needs.

14.3 Ease of Use

Select a diagnostic tool that is easy to use. A tool with an intuitive interface and clear instructions will help you work more efficiently and reduce the risk of errors.

14.4 Reliability

Choose a diagnostic tool from a reputable manufacturer known for producing reliable products. A reliable tool will provide accurate results and withstand the rigors of daily use in a workshop environment.

14.5 Support and Training

Ensure that the manufacturer provides adequate support and training for the diagnostic tool. Good support and training will help you get the most out of the tool and ensure that you can use it safely and effectively.

15. Understanding the Autel MaxiSYS MS906 Pro Features

The Autel MaxiSYS MS906 Pro offers a comprehensive suite of features designed to enhance vehicle diagnostics and maintenance. These features include:

15.1 Extensive Vehicle Coverage

The MS906 Pro supports a wide range of vehicle makes and models, providing comprehensive diagnostic coverage for most vehicles on the road.

15.2 Advanced Diagnostic Functions

The MS906 Pro offers advanced diagnostic functions such as ECU coding, bi-directional control, and live data streaming, allowing technicians to perform in-depth diagnostics and troubleshooting.

15.3 Wireless Connectivity

With wireless connectivity, the MS906 Pro allows technicians to move freely around the vehicle while performing diagnostics, enhancing convenience and efficiency.

15.4 User-Friendly Interface

The MS906 Pro features an intuitive user interface that makes it easy to navigate through diagnostic procedures and access the necessary functions and data.

15.5 Regular Updates

Autel regularly releases software updates for the MS906 Pro, ensuring that the tool remains current with the latest vehicle models and diagnostic procedures.

16. Optimizing Your Workshop for Safety and Efficiency

To create a safe and efficient workshop, focus on implementing best practices in safety and organization.

16.1 Ergonomic Workstations

Design workstations that minimize physical strain and promote good posture. Use adjustable chairs and tables to accommodate technicians of different heights.

16.2 Proper Lighting

Ensure adequate lighting in all work areas. Good lighting reduces eye strain and improves visibility, enhancing both safety and efficiency.

16.3 Organized Tool Storage

Implement an organized tool storage system. Keep tools in designated locations so they can be easily found and returned. This reduces clutter and improves efficiency.

16.4 Regular Maintenance

Perform regular maintenance on equipment and tools. Keep tools clean and lubricated, and replace worn or damaged parts promptly.

16.5 Clear Signage

Use clear signage to identify hazards and safety procedures. Post signs near electrical panels, hazardous materials, and emergency exits.

17. The Role of Technology in Enhancing Safety

Technology plays a crucial role in enhancing safety in automotive repair. Advanced diagnostic tools like the Autel MaxiSYS MS906 Pro incorporate safety features that help protect technicians from electrical shock and other hazards.

17.1 Insulation

Diagnostic tools are designed with insulation to protect technicians from electric shock. Insulation prevents electrical current from flowing through the technician’s body in case of a fault.

17.2 Grounding

Diagnostic tools are grounded to provide a safe path for electrical current in case of a fault. Grounding helps to prevent electric shock by diverting the current away from the technician.

17.3 Overload Protection

Diagnostic tools are equipped with overload protection to prevent damage from excessive electrical current. Overload protection automatically shuts off the tool if the current exceeds a safe level.

17.4 Error Detection

Diagnostic tools incorporate error detection features to identify potential problems before they lead to accidents. Error detection helps to prevent electrical shock and other hazards by alerting the technician to potential problems.

18. Investing in Training and Certification

Investing in training and certification is essential for ensuring that technicians have the knowledge and skills needed to work safely and efficiently.

18.1 Formal Training Programs

Enroll technicians in formal training programs that cover electrical safety, diagnostic procedures, and tool operation. Formal training programs provide comprehensive instruction and hands-on experience.

18.2 Certification Programs

Encourage technicians to pursue certification in automotive repair. Certification demonstrates that technicians have met industry standards for knowledge and skills.

18.3 Continuing Education

Provide technicians with opportunities for continuing education. Continuing education helps technicians stay current with the latest technologies and safety procedures.

18.4 In-House Training

Conduct in-house training sessions to reinforce safety procedures and provide hands-on practice with diagnostic tools. In-house training can be tailored to the specific needs of your workshop.

19. Why Choose CARDIAGTECH.NET for Your Diagnostic Needs?

CARDIAGTECH.NET is your trusted source for high-quality diagnostic tools and equipment. Here are some reasons to choose CARDIAGTECH.NET for your diagnostic needs:

19.1 Wide Selection

CARDIAGTECH.NET offers a wide selection of diagnostic tools from leading manufacturers. You can find the right tool for your needs, whether you work on domestic or foreign vehicles.

19.2 Competitive Prices

CARDIAGTECH.NET offers competitive prices on all diagnostic tools and equipment. You can save money without sacrificing quality or performance.

19.3 Expert Support

CARDIAGTECH.NET provides expert support to help you choose the right diagnostic tools and equipment. Our knowledgeable staff can answer your questions and provide technical assistance.

19.4 Fast Shipping

CARDIAGTECH.NET offers fast shipping on all orders. You can get the diagnostic tools and equipment you need quickly and easily.

19.5 Customer Satisfaction

CARDIAGTECH.NET is committed to customer satisfaction. We stand behind our products and offer a satisfaction guarantee.

20. Contact CARDIAGTECH.NET Today

Don’t compromise on safety and efficiency in your automotive repair shop. Contact CARDIAGTECH.NET today to learn more about our high-quality diagnostic tools, safety equipment, and training programs. Our team is ready to assist you in selecting the right solutions for your needs and ensuring a safe and productive working environment.

- Address: 276 Reock St, City of Orange, NJ 07050, United States

- WhatsApp: +1 (641) 206-8880

- Website: CARDIAGTECH.NET

By implementing these safety measures and utilizing the advanced features of the Autel MaxiSYS MS906 Pro, you can significantly reduce the risk of electric shock and create a safer, more efficient working environment. Remember, safety is not just a priority; it’s a fundamental aspect of professional automotive repair.

FAQ About Autel MS906 and Electric Shock Prevention

1. What are the primary causes of electric shock when using the Autel MS906?

Electric shocks can occur due to damaged cables, exposure to moisture, or improper grounding. Regularly inspect your equipment to prevent these issues.

2. How can I ensure proper grounding when using the Autel MS906?

Ensure both the Autel MS906 and the vehicle are properly grounded. Check grounding connections regularly for security and corrosion.

3. What PPE should I use to protect myself from electric shock?

Use insulated gloves, safety glasses, and non-conductive footwear to minimize the risk of electric shock.

4. What should I do if the Autel MS906 gets wet?

Dry the device thoroughly before use. Avoid using the Autel MS906 in wet or damp conditions to prevent electric shock.

5. Why is proper training important for using the Autel MS906 safely?

Proper training covers the risks of electric shock, safety measures, and best practices, ensuring technicians are aware of how to use the tool safely.

6. What should I do immediately after someone receives an electric shock while using the Autel MS906?

Turn off the power source, provide first aid, and seek immediate medical attention.

7. How often should I inspect my Autel MS906 for damage?

Regularly inspect the Autel MS906 and its accessories before each use to identify any signs of damage.

8. Can I modify the Autel MS906 to improve its performance?

No, do not modify the Autel MS906 or its accessories. Modifications can compromise safety features and increase the risk of electric shock.

9. What kind of safety program should my workshop have to prevent electric shock?

Implement a comprehensive safety program that includes regular safety meetings, hazard assessments, and emergency response plans.

10. Where can I find reliable Autel diagnostic tools and safety equipment?

CARDIAGTECH.NET offers a range of high-quality diagnostic tools, safety equipment, and training programs to help automotive technicians work safely and efficiently. Contact them at +1 (641) 206-8880 or visit CARDIAGTECH.NET for more information.

This detailed guide provides comprehensive information on preventing electric shocks when using the Autel MS906, ensuring a safer and more efficient working environment for automotive technicians.