The Autel Abs Chevy Truck Diagnostic tool offers comprehensive solutions for diagnosing and resolving ABS issues in Chevy trucks. This guide, brought to you by CARDIAGTECH.NET, will provide expert insights into using Autel diagnostic tools to maintain your Chevy truck’s braking system effectively. Ensure optimal performance and safety with advanced diagnostic capabilities, pinpointing ABS faults quickly and accurately, which enhances vehicle maintenance and guarantees a smooth driving experience.

1. Understanding the Importance of ABS Diagnostics for Chevy Trucks

The Anti-lock Braking System (ABS) is vital for maintaining control during sudden stops, especially in Chevy trucks. Regular diagnostic checks are crucial to ensure its proper function. ABS diagnostics involves assessing the sensors, hydraulic units, and electronic control units (ECUs) to pinpoint any malfunctions that could compromise braking performance. Proactive maintenance using tools like the Autel ABS Chevy Truck Diagnostic can prevent accidents and extend the lifespan of your vehicle’s braking system.

1.1. Why Regular ABS Checks are Essential

Regular checks of your Chevy truck’s ABS are vital for several reasons. First, they ensure your vehicle’s safety by confirming the ABS is ready to activate when needed, preventing wheel lockup and maintaining steering control during emergency braking. Second, early detection of issues like sensor failures or hydraulic problems can prevent costly repairs later on. Finally, routine diagnostics contribute to the overall reliability and longevity of your truck, keeping it running smoothly and safely on the road.

1.2. Common ABS Issues in Chevy Trucks

Chevy trucks, like all vehicles, are susceptible to common ABS issues that can compromise their safety and performance. These problems often include faulty wheel speed sensors that provide incorrect data to the ABS module, leading to delayed or incorrect ABS activation. Hydraulic pump failures, another frequent issue, can prevent the system from building the necessary pressure to modulate braking force effectively. Additionally, corroded or damaged wiring can disrupt the communication between the ABS components, resulting in system failure. Addressing these issues promptly with tools like the Autel ABS Chevy Truck Diagnostic is essential to maintain optimal braking performance and safety.

2. Choosing the Right Autel Diagnostic Tool

Selecting the right Autel diagnostic tool for your Chevy truck is crucial for efficient and accurate ABS diagnostics. Autel offers a range of tools, each designed with specific capabilities to meet various diagnostic needs. When choosing a tool, consider factors such as the types of tests it can perform (e.g., live data streaming, active tests), its compatibility with your truck’s model and year, and its ease of use. Investing in a high-quality Autel tool ensures that you can effectively diagnose and resolve ABS issues, keeping your Chevy truck safe and reliable.

2.1. Top Autel Scanners for Chevy Truck ABS Diagnostics

When it comes to diagnosing ABS issues in Chevy trucks, several Autel scanners stand out for their comprehensive features and reliability. The Autel MaxiSYS MS906BT is highly recommended for its extensive vehicle coverage, including detailed ABS diagnostics. It offers advanced functions such as live data streaming, active tests, and ECU coding, providing a thorough analysis of the ABS performance. Another excellent option is the Autel MaxiCOM MK808BT, which combines powerful diagnostic capabilities with user-friendly operation, making it suitable for both professional mechanics and DIY enthusiasts. Lastly, the Autel AL619 is a cost-effective choice that still provides essential ABS diagnostic functions, such as reading and clearing ABS codes, making it a great entry-level tool for Chevy truck owners. Each of these scanners can help you maintain the safety and efficiency of your vehicle’s braking system.

2.2. Key Features to Look for in an ABS Diagnostic Tool

When selecting an ABS diagnostic tool for your Chevy truck, several key features can significantly enhance its effectiveness. One of the most important is the ability to read and clear ABS codes, allowing you to identify the specific issues affecting the system. Live data streaming is also crucial, as it provides real-time information from the ABS sensors and components, helping you diagnose intermittent problems. Bi-directional control, or active tests, enables you to command the ABS module to perform specific functions, such as activating the pump or solenoids, to verify their operation. Additionally, compatibility with a wide range of Chevy truck models and years is essential to ensure the tool can accurately diagnose your vehicle. These features, combined with user-friendly operation and reliable performance, will ensure you can maintain your Chevy truck’s ABS effectively.

3. Preparing for the Diagnostic Process

Before you begin diagnosing your Chevy truck’s ABS, proper preparation is key to ensuring a smooth and accurate process. Start by gathering all necessary tools, including your Autel diagnostic scanner, a reliable OBD-II cable, and any adapters required for your specific truck model. It’s also helpful to have a multimeter on hand for testing electrical components. Next, consult your Chevy truck’s service manual to understand the specific ABS system layout and component locations. Finally, ensure your Autel scanner is updated with the latest software and vehicle-specific data to access the most accurate diagnostic information. Taking these preparatory steps will help you efficiently identify and resolve any ABS issues.

3.1. Gathering Necessary Tools and Equipment

Gathering the right tools and equipment is essential for effectively diagnosing ABS issues in your Chevy truck. Start with a high-quality Autel diagnostic scanner capable of reading and clearing ABS codes, such as the Autel MaxiSYS MS906BT or MaxiCOM MK808BT. Ensure you have a reliable OBD-II cable to connect the scanner to your truck’s diagnostic port. A multimeter is also necessary for testing electrical components like wheel speed sensors and wiring. Additionally, a set of basic hand tools, including wrenches, sockets, and screwdrivers, will be useful for accessing and inspecting ABS components. Finally, having a vehicle-specific repair manual can provide valuable information about the ABS system layout and testing procedures. With these tools on hand, you’ll be well-prepared to diagnose and address any ABS problems in your Chevy truck.

3.2. Understanding Your Chevy Truck’s ABS System

To effectively diagnose ABS issues in your Chevy truck, a thorough understanding of its ABS system is crucial. Start by familiarizing yourself with the main components, including the wheel speed sensors, ABS control module, hydraulic control unit, and brake lines. The wheel speed sensors monitor the rotational speed of each wheel and send this data to the ABS control module, which uses it to detect wheel lockup. The hydraulic control unit modulates brake pressure to prevent lockup during hard braking. Knowing the location and function of each component will help you target specific areas during the diagnostic process. Additionally, consulting your Chevy truck’s service manual will provide detailed diagrams and troubleshooting steps specific to your model and year, enhancing your ability to accurately diagnose and resolve ABS problems.

4. Step-by-Step Guide to Performing Autel ABS Diagnostics

Performing Autel ABS diagnostics on your Chevy truck involves a systematic approach to accurately identify and resolve issues. Start by connecting your Autel diagnostic scanner to the OBD-II port and turning on the ignition. Navigate to the ABS diagnostic section in the scanner’s menu and initiate a scan to retrieve any stored ABS codes. Record these codes for reference, then use the scanner to view live data from the wheel speed sensors and other ABS components. Perform active tests, such as activating the ABS pump or solenoids, to check their functionality. Based on the diagnostic information, follow troubleshooting steps outlined in your service manual to pinpoint the root cause of the problem. Once identified, replace faulty components and clear the ABS codes. Finally, perform a test drive to ensure the ABS system is functioning correctly.

4.1. Connecting the Autel Scanner to Your Chevy Truck

Connecting your Autel scanner to your Chevy truck is a straightforward process that begins by locating the OBD-II port, typically found under the dashboard on the driver’s side. Ensure your truck’s ignition is turned off before plugging the Autel scanner’s OBD-II connector into the port. Once connected, turn the ignition to the “on” position without starting the engine. The Autel scanner should power up automatically. If not, check the connection and ensure the scanner is properly charged. Navigate through the scanner’s menu to select your vehicle’s make, model, and year. This will allow the scanner to communicate effectively with your Chevy truck’s computer system, enabling you to perform accurate ABS diagnostics.

4.2. Reading and Interpreting ABS Codes

Reading and interpreting ABS codes is a critical step in diagnosing your Chevy truck’s braking system. Once your Autel scanner is connected, navigate to the ABS diagnostic section and initiate a scan. The scanner will retrieve any stored ABS codes, which are alphanumeric identifiers that correspond to specific issues within the ABS system. For example, a code like “C0035” might indicate a problem with the front right wheel speed sensor. Consult your vehicle’s service manual or a reliable online database to understand the meaning of each code. Pay attention to the code descriptions, as they often provide clues about the location and nature of the fault. This information will guide your troubleshooting efforts and help you pinpoint the underlying problem affecting your Chevy truck’s ABS.

4.3. Using Live Data to Diagnose ABS Issues

Using live data is an essential technique for diagnosing intermittent or complex ABS issues in your Chevy truck. Once your Autel scanner is connected and you’ve selected the ABS diagnostic section, choose the option to view live data. This will display real-time information from various ABS components, such as wheel speed sensors, hydraulic control unit, and ABS module. Monitor the wheel speed sensor readings while driving at a slow speed to check for any inconsistencies or dropouts, which could indicate a faulty sensor or wiring issue. Compare the data from each sensor to identify discrepancies. Also, observe the hydraulic control unit’s pressure readings to ensure it’s functioning correctly. By analyzing live data, you can identify subtle anomalies that may not trigger a specific ABS code, enabling you to diagnose and resolve issues more effectively.

4.4. Performing Active Tests with Autel Scanners

Performing active tests with your Autel scanner allows you to directly control and evaluate the functionality of ABS components in your Chevy truck. After connecting the scanner and accessing the ABS diagnostic section, select the active test option. This feature enables you to command the ABS module to perform specific actions, such as activating the ABS pump, opening and closing solenoids, and engaging individual wheel brakes. By observing the response of each component during these tests, you can verify their operation and identify any malfunctions. For example, you can activate the ABS pump to check for proper pressure build-up or cycle the solenoids to ensure they are responding correctly. Active tests provide valuable insights into the health and performance of the ABS system, helping you diagnose and resolve issues with greater precision.

5. Common ABS Codes and Their Meanings

Understanding common ABS codes is crucial for efficiently diagnosing issues in your Chevy truck. For example, code C0040 indicates a problem with the right front wheel speed sensor, which could be due to a faulty sensor, damaged wiring, or a dirty sensor ring. Code C0045 points to a similar issue with the left front wheel speed sensor. Code C0051 suggests a malfunction in the ABS control module, which may require replacement or reprogramming. Code C0265 indicates a problem with the ABS motor relay circuit, which can affect the operation of the ABS pump. By familiarizing yourself with these common codes and their meanings, you can quickly identify potential issues and focus your diagnostic efforts on the most likely causes, saving time and ensuring accurate repairs.

5.1. Decoding ABS Trouble Codes

Decoding ABS trouble codes is a critical step in diagnosing your Chevy truck’s braking system. Each code consists of a letter followed by four numbers, providing specific information about the issue. The letter indicates the system affected: “C” for chassis, “B” for body, “P” for powertrain, and “U” for network communication. The first number specifies the subsystem, while the remaining numbers pinpoint the specific component or circuit with the problem. For instance, code C0035 indicates a fault in the front right wheel speed sensor circuit. By consulting a reliable code database or your vehicle’s service manual, you can determine the exact meaning of each code and understand the potential causes. This knowledge is essential for effective troubleshooting and accurate repairs, ensuring your Chevy truck’s ABS functions correctly.

5.2. Interpreting Sensor-Related Codes

Interpreting sensor-related codes is essential for diagnosing ABS issues in your Chevy truck. These codes typically indicate problems with wheel speed sensors, which are critical for monitoring wheel rotation and detecting lock-up. A common code, such as C0035 or C0040, indicates a fault in the front wheel speed sensor circuit. These codes can result from a faulty sensor, damaged wiring, a dirty sensor ring, or an issue with the ABS module. When you encounter a sensor-related code, start by visually inspecting the sensor and its wiring for any signs of damage or corrosion. Use a multimeter to test the sensor’s resistance and signal output. If the sensor appears to be functioning correctly, check the wiring for continuity and shorts. Addressing these issues promptly will help restore proper ABS function and ensure your Chevy truck’s safety.

5.3. Addressing Module and Pump Codes

Addressing module and pump codes is crucial for resolving complex ABS issues in your Chevy truck. These codes often indicate significant problems that can severely impact the system’s performance. A module-related code, such as C0051, suggests a malfunction within the ABS control module itself, which may require reprogramming or replacement. Pump-related codes, like C0265, point to issues with the ABS pump motor relay circuit, which can prevent the pump from building necessary pressure. When dealing with these codes, start by checking the power supply and ground connections to the module and pump. Use a multimeter to verify proper voltage and continuity. If the wiring and connections are good, the module or pump may need further testing or replacement. Given the complexity of these components, consulting a professional mechanic may be necessary to ensure accurate diagnosis and repair.

6. Performing Basic ABS Component Tests

Performing basic ABS component tests is crucial for accurately diagnosing issues in your Chevy truck. Start by visually inspecting the wheel speed sensors for damage or debris. Use a multimeter to check the sensor’s resistance, comparing it to the manufacturer’s specifications. Next, inspect the wiring and connectors for corrosion or damage. Test the continuity of the wiring harness to ensure there are no breaks or shorts. You can also test the ABS pump by activating it with your Autel scanner and listening for proper operation. Finally, inspect the brake lines for leaks or damage. These basic tests will help you identify common ABS problems and guide your repair efforts effectively.

6.1. Testing Wheel Speed Sensors

Testing wheel speed sensors is a fundamental step in diagnosing ABS issues in your Chevy truck. These sensors are critical for monitoring wheel rotation and detecting lock-up. Begin by visually inspecting the sensor and its wiring for any signs of damage or corrosion. Use a multimeter to measure the sensor’s resistance, comparing the reading to the manufacturer’s specifications. A significantly high or low resistance indicates a faulty sensor. You can also perform a dynamic test by connecting the multimeter to the sensor and spinning the wheel. The multimeter should display a fluctuating voltage or AC signal. If there is no signal or an erratic signal, the sensor is likely defective. Additionally, check the sensor ring (tone ring) for damage or debris, as this can also affect sensor readings. Properly testing wheel speed sensors will help you pinpoint ABS issues accurately and ensure your Chevy truck’s braking system functions correctly.

6.2. Inspecting ABS Wiring and Connectors

Inspecting ABS wiring and connectors is a critical part of diagnosing ABS issues in your Chevy truck. Begin by visually examining the wiring harness for any signs of damage, such as cuts, abrasions, or melted insulation. Pay close attention to areas where the wiring is exposed to heat or abrasion. Check the connectors for corrosion, loose pins, or broken locks. Use a multimeter to test the continuity of the wiring, ensuring there are no breaks or shorts. Disconnect the connectors and inspect the pins for corrosion or damage. Clean any corroded connectors with electrical contact cleaner and ensure they are properly seated when reconnected. Damaged or corroded wiring and connectors can disrupt the communication between ABS components, leading to system malfunctions. Thorough inspection and repair of these components will help ensure the reliability of your Chevy truck’s ABS.

6.3. Checking the ABS Hydraulic Unit

Checking the ABS hydraulic unit is an essential step in diagnosing ABS issues in your Chevy truck. This unit modulates brake pressure to prevent wheel lock-up during hard braking. Start by visually inspecting the unit for any signs of leaks or damage. Check the brake lines connected to the unit for corrosion or cracks. With your Autel scanner, perform active tests to activate the ABS pump and solenoids within the hydraulic unit. Listen for proper operation and check for any unusual noises. If the pump does not activate or the solenoids do not cycle correctly, there may be an issue with the hydraulic unit. Additionally, check the brake fluid level and condition, as low or contaminated fluid can affect the unit’s performance. Addressing any issues with the ABS hydraulic unit will help ensure your Chevy truck’s braking system functions safely and effectively.

7. Advanced Diagnostic Techniques

Advanced diagnostic techniques can help you tackle complex ABS issues in your Chevy truck that may not be easily resolved with basic methods. One such technique is using an oscilloscope to analyze the waveform patterns of wheel speed sensors, which can reveal subtle issues like signal interference or intermittent dropouts. Another advanced method involves performing a brake system bleed with the Autel scanner to ensure proper fluid flow and pressure throughout the ABS system. Additionally, you can use the scanner to perform ECU coding and programming, which may be necessary after replacing the ABS control module. These advanced techniques require specialized knowledge and equipment but can provide valuable insights into the ABS system’s operation and help you resolve challenging diagnostic problems.

7.1. Using Oscilloscopes for ABS Diagnostics

Using oscilloscopes for ABS diagnostics can provide a detailed analysis of sensor signals and electrical circuits in your Chevy truck. An oscilloscope allows you to visualize the waveform patterns of wheel speed sensors, which can reveal subtle issues such as signal interference, intermittent dropouts, or incorrect amplitude. Connect the oscilloscope to the sensor signal wire and ground, then spin the wheel to generate a signal. Observe the waveform for any abnormalities. A clean, consistent waveform indicates a healthy sensor, while distorted or erratic waveforms suggest potential problems. You can also use an oscilloscope to check the voltage and current in ABS circuits, helping you identify shorts, opens, or excessive resistance. Oscilloscope diagnostics require specialized knowledge and equipment but can provide valuable insights into the ABS system’s operation, enabling you to resolve complex issues with greater precision.

7.2. Performing ABS Brake Bleeding with Autel Tools

Performing ABS brake bleeding with Autel tools is an essential maintenance procedure for your Chevy truck to ensure optimal braking performance. Air trapped in the ABS hydraulic unit can compromise the system’s ability to modulate brake pressure effectively. Autel scanners with bi-directional control capabilities allow you to activate the ABS pump and solenoids during the bleeding process, helping to remove trapped air. To perform ABS brake bleeding, connect your Autel scanner to the vehicle and navigate to the ABS service functions. Follow the on-screen instructions to activate the ABS pump and open the solenoids. Bleed each brake caliper in the correct sequence, typically starting with the wheel farthest from the master cylinder. Ensure that you use the correct type of brake fluid and maintain the fluid level in the master cylinder throughout the process. Properly bleeding the ABS system will help restore firm brake pedal feel and ensure reliable ABS operation.

7.3. ECU Coding and Programming for ABS Modules

ECU coding and programming for ABS modules may be necessary when replacing the ABS control module in your Chevy truck. The new module needs to be configured to match your vehicle’s specific parameters and options. Autel scanners with ECU coding and programming capabilities allow you to perform this task. Before starting, ensure that you have the correct software and vehicle-specific data. Connect your Autel scanner to the vehicle and navigate to the ECU coding or programming section. Follow the on-screen instructions to enter the required information, such as the vehicle identification number (VIN) and any specific option codes. The scanner will then program the new ABS module with the correct settings. This process ensures that the ABS system functions correctly with the other vehicle systems. Improper coding or programming can lead to system malfunctions or safety issues, so it is essential to follow the instructions carefully or consult a professional mechanic.

8. Tips for Effective ABS Diagnostics

To achieve effective ABS diagnostics on your Chevy truck, adopt a systematic and thorough approach. Always start with a visual inspection of all ABS components, including sensors, wiring, connectors, and the hydraulic unit. Use your Autel scanner to read and record any stored ABS codes, then research the meaning of each code to understand the potential issues. Utilize live data to monitor sensor readings and component operation in real-time. Perform active tests to directly control ABS components and verify their functionality. When troubleshooting, follow the diagnostic steps outlined in your vehicle’s service manual. Take accurate notes and document your findings to track your progress and identify patterns. By following these tips, you can diagnose ABS issues accurately and efficiently, ensuring your Chevy truck’s braking system functions safely and reliably.

8.1. Maintaining Accurate Records

Maintaining accurate records during ABS diagnostics is crucial for efficient and effective troubleshooting of your Chevy truck. Start by documenting all diagnostic steps, including the ABS codes retrieved, live data readings, and active test results. Record the date, time, and conditions under which the diagnostics were performed. Note any visual inspections, component tests, and their outcomes. Keep track of any parts replaced and the reasons for their replacement. Use a digital tool or a dedicated notebook to organize your records. Accurate documentation helps you track your progress, identify patterns, and avoid repeating steps. It also provides valuable information for future reference and can assist other mechanics if needed. Good record-keeping ensures that you approach ABS diagnostics systematically and resolve issues effectively.

8.2. Staying Updated with the Latest ABS Technology

Staying updated with the latest ABS technology is essential for effectively diagnosing and repairing ABS systems in your Chevy truck. ABS technology is constantly evolving, with new features and components being introduced regularly. To stay informed, subscribe to industry publications, attend training seminars, and participate in online forums and communities. Regularly update your Autel scanner with the latest software and vehicle-specific data to ensure compatibility with new ABS systems. Familiarize yourself with the latest diagnostic techniques and tools. By staying current with ABS technology, you can accurately diagnose and resolve even the most complex ABS issues, ensuring your Chevy truck’s braking system functions safely and reliably.

8.3. Seeking Professional Help When Needed

Seeking professional help when needed is a wise decision when diagnosing complex ABS issues in your Chevy truck. While Autel scanners and DIY diagnostic techniques can be helpful, some problems require specialized knowledge and equipment. If you encounter persistent ABS codes that you cannot resolve, or if you are unsure about performing advanced diagnostic procedures, consult a qualified mechanic. A professional mechanic has the experience and expertise to accurately diagnose and repair intricate ABS problems. They can also perform ECU coding and programming, which may be necessary after replacing the ABS control module. Don’t hesitate to seek professional help when needed to ensure the safety and reliability of your Chevy truck’s braking system.

9. Maintaining Your Chevy Truck’s ABS

Maintaining your Chevy truck’s ABS is crucial for ensuring its long-term safety and reliability. Regular inspections and proactive maintenance can prevent many common ABS issues. Check the brake fluid level and condition regularly, replacing it as recommended by the manufacturer. Inspect the wheel speed sensors and wiring for damage or corrosion. Keep the sensor rings (tone rings) clean and free of debris. Perform ABS brake bleeding every two to three years to remove trapped air from the hydraulic unit. Address any ABS codes promptly to prevent minor issues from escalating into major problems. By following these maintenance practices, you can keep your Chevy truck’s ABS functioning optimally and ensure safe braking performance.

9.1. Regular Inspection and Maintenance Schedules

Regular inspection and maintenance schedules are vital for ensuring the optimal performance and longevity of your Chevy truck’s ABS. Start by inspecting the brake fluid level and condition at least every six months. Replace the brake fluid every two to three years to prevent contamination and maintain proper hydraulic pressure. Inspect the wheel speed sensors and wiring for damage or corrosion during each brake service. Clean the sensor rings (tone rings) regularly to ensure accurate sensor readings. Perform ABS brake bleeding every two to three years to remove trapped air and maintain firm brake pedal feel. Check the brake pads and rotors regularly, as worn components can affect ABS performance. By following a regular inspection and maintenance schedule, you can identify and address potential issues early, preventing costly repairs and ensuring the safety of your Chevy truck.

9.2. Choosing Quality Replacement Parts

Choosing quality replacement parts is crucial when repairing your Chevy truck’s ABS to ensure long-term reliability and safety. When replacing wheel speed sensors, hydraulic units, or other ABS components, opt for parts from reputable manufacturers that meet or exceed OEM specifications. Avoid low-cost, generic parts, as they may not perform reliably and can potentially damage the ABS system. Research the brands and read reviews to ensure you are selecting high-quality parts. Use the correct part numbers and verify compatibility with your vehicle’s make, model, and year. Installing quality replacement parts will help restore proper ABS function and ensure your Chevy truck’s braking system operates safely and effectively.

9.3. Monitoring ABS Performance After Repairs

Monitoring ABS performance after repairs is essential to ensure that the system is functioning correctly and that the repairs have been effective. After completing any ABS repairs, use your Autel scanner to clear the ABS codes and perform a system test. Monitor the wheel speed sensor readings and other ABS data while driving to check for any abnormalities. Perform a series of controlled braking tests to verify that the ABS is activating properly and preventing wheel lock-up. Pay attention to the brake pedal feel and ensure that it is firm and consistent. If any ABS codes reappear or if you notice any issues with braking performance, re-inspect the system and address any remaining problems. Monitoring ABS performance after repairs will help ensure that your Chevy truck’s braking system is functioning safely and reliably.

10. Conclusion: Ensuring Safety with Autel ABS Diagnostics

In conclusion, ensuring safety with Autel ABS diagnostics is paramount for maintaining your Chevy truck’s braking system. Regular, thorough diagnostics using Autel tools enable you to identify and resolve ABS issues promptly, preventing potential accidents and ensuring reliable performance. By understanding the importance of ABS, choosing the right diagnostic tools, and following systematic diagnostic procedures, you can keep your Chevy truck’s ABS in optimal condition. Remember to maintain accurate records, stay updated with the latest technology, and seek professional help when needed. With proper care and attention, you can ensure your Chevy truck provides safe and dependable braking performance for years to come.

Don’t wait until it’s too late. Prioritize your safety and the safety of others on the road. Contact CARDIAGTECH.NET today at 276 Reock St, City of Orange, NJ 07050, United States or via Whatsapp at +1 (641) 206-8880, or visit our website at CARDIAGTECH.NET to learn more about how our Autel ABS Chevy Truck Diagnostic solutions can help you maintain your vehicle’s braking system effectively. Our team is ready to assist you with expert advice and top-quality diagnostic tools.

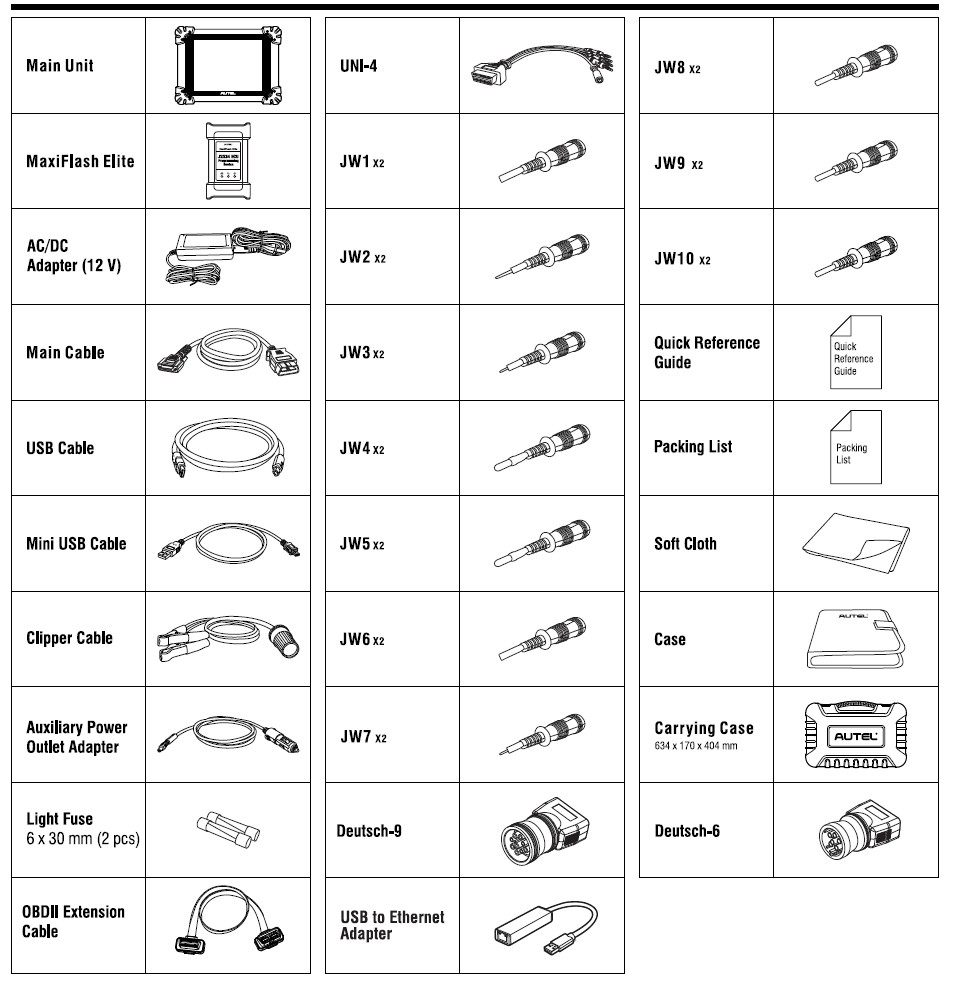

Autel Maxisys MS908CV II Package List, diagnostic tool set including cables, adapters and accessories for commercial vehicle diagnostics

Autel Maxisys MS908CV II Package List, diagnostic tool set including cables, adapters and accessories for commercial vehicle diagnostics

FAQ: Autel ABS Chevy Truck Diagnostic

1. What is Autel ABS Chevy Truck Diagnostic?

Autel ABS Chevy Truck Diagnostic refers to the process of using Autel diagnostic tools to identify and resolve issues within the Anti-lock Braking System (ABS) of Chevy trucks. These tools help diagnose problems by reading ABS codes, monitoring live data, and performing active tests.

2. Why is ABS diagnostics important for Chevy trucks?

ABS diagnostics is crucial for ensuring the safety and reliability of Chevy trucks. The ABS prevents wheel lock-up during hard braking, maintaining steering control. Regular diagnostics help identify and address potential ABS issues before they lead to accidents.

3. Which Autel scanner is best for Chevy truck ABS diagnostics?

Several Autel scanners are suitable for Chevy truck ABS diagnostics, including the Autel MaxiSYS MS906BT, Autel MaxiCOM MK808BT, and Autel AL619. The best choice depends on your specific needs and budget.

4. What are common ABS codes for Chevy trucks?

Common ABS codes for Chevy trucks include C0035 (front right wheel speed sensor fault), C0040 (front left wheel speed sensor fault), C0051 (ABS control module malfunction), and C0265 (ABS motor relay circuit problem).

5. How do I perform ABS diagnostics on my Chevy truck?

To perform ABS diagnostics, connect your Autel scanner to the OBD-II port, read and record ABS codes, view live data from sensors, perform active tests, and follow the troubleshooting steps outlined in your service manual.

6. What are the key features to look for in an ABS diagnostic tool?

Key features to look for in an ABS diagnostic tool include the ability to read and clear ABS codes, view live data, perform active tests, compatibility with your truck model, and user-friendly operation.

7. How often should I check my Chevy truck’s ABS?

You should check your Chevy truck’s ABS at least every six months or during each brake service. Regular inspections can help identify and address potential issues early, preventing costly repairs and ensuring safety.

8. Can I perform ABS brake bleeding with an Autel scanner?

Yes, many Autel scanners with bi-directional control capabilities allow you to perform ABS brake bleeding. This process helps remove trapped air from the hydraulic unit, ensuring optimal braking performance.

9. What should I do if I encounter persistent ABS codes?

If you encounter persistent ABS codes that you cannot resolve, consult a qualified mechanic. Complex ABS issues may require specialized knowledge and equipment to diagnose and repair accurately.

10. Where can I find quality replacement parts for my Chevy truck’s ABS?

You can find quality replacement parts for your Chevy truck’s ABS from reputable auto parts stores or online retailers. Choose parts from trusted manufacturers that meet or exceed OEM specifications to ensure reliability and safety.