Seeing your check engine light illuminate can be concerning, especially when you’re unsure of the underlying issue. Understanding the language of your vehicle when it signals a problem is crucial for proactive maintenance and can save you time and money. This is where Diagnostic Trouble Codes (DTCs) come into play. But a basic OBD-II code is made up of what characters, and what do they actually mean? This article will break down the anatomy of an OBD-II code, explaining each character and how they contribute to diagnosing your vehicle’s health.

What Exactly is a DTC Code?

A Diagnostic Trouble Code, or DTC, is essentially your vehicle’s way of communicating a problem. It’s a standardized code used across the automotive industry to pinpoint malfunctions within a car or truck. Think of the check engine light as a general alarm, while a DTC is the specific message explaining why the alarm is going off. These codes, sometimes referred to as engine fault codes or vehicle fault codes, are accessed using a diagnostic scanner that plugs into your vehicle’s OBD-II port.

For vehicle owners and fleet managers alike, a fundamental understanding of DTCs can be incredibly beneficial. It empowers you to understand the nature of vehicle issues and take informed actions, whether it’s a simple fix or a trip to a mechanic. Let’s delve deeper into the world of DTCs and how they function.

The Origin of DTCs: OBD Systems

DTCs are generated by your vehicle’s On-Board Diagnostics (OBD) system. This system is constantly monitoring various components and systems within your vehicle. When the OBD system detects a problem or a reading outside of normal parameters, it generates a DTC and often illuminates the Malfunction Indicator Lamp (MIL), better known as the check engine light. The OBD system is designed to not only identify faults but also to provide a standardized way for external devices, like OBD scanners, to communicate with the vehicle’s computer.

Early OBD systems, now known as OBD-I, were varied and manufacturer-specific, leading to inconsistencies in diagnostic procedures. To standardize vehicle diagnostics, OBD-II was developed. Today, two primary standards are used for reading DTCs:

- OBD-II: The standard for most light-duty and medium-duty vehicles.

- J1939: The standard primarily used for heavy-duty vehicles and equipment.

The introduction of OBD-II marked a significant step towards standardization. The Society of Automotive Engineers (SAE) established a universal list of DTCs, ensuring common codes across all manufacturers. While OBD-II is widely adopted, it’s worth noting that vehicle manufacturers can still include manufacturer-specific DTCs to address unique vehicle features or complex issues not covered by the generic codes. However, these manufacturer-specific codes often require specialized knowledge or tools to interpret fully.

Determining OBD-II or J1939 Compliance

Knowing whether your vehicle is OBD-II or J1939 compliant is the first step in understanding how to interpret potential DTCs.

OBD-II Compliance:

- In the United States, all cars and light trucks manufactured and sold after January 1, 1996, are mandated to be OBD-II compliant.

J1939 Compliance:

- J1939 compliance is common in most diesel engine vehicles and heavy equipment.

- It is the industry standard for the majority of heavy-duty trucks and buses.

If you are uncertain about your vehicle’s compliance, the best resources are your vehicle’s owner’s manual, online vehicle specifications databases, or your dealership.

OBD-II Port Diagram

OBD-II Port Diagram

Breaking Down the OBD-II DTC Structure: What Characters Are Used?

OBD-II DTCs are structured as a five-character alphanumeric code. Each character provides specific information, allowing for a systematic diagnosis of vehicle problems. Understanding what characters a basic OBD-II code is made up of is key to deciphering these codes. Let’s examine each position in detail:

1. First Character: The System Category (Letter)

The very first character of a DTC is always a letter, indicating the primary vehicle system where the fault has occurred. There are four possible letters:

- P (Powertrain): This signifies issues within the powertrain system, which includes the engine, transmission, fuel system, and related components. Powertrain codes are the most frequently encountered DTCs.

- C (Chassis): “C” codes point to problems in chassis systems. These are typically mechanical systems outside the passenger compartment, such as steering, suspension, and braking systems (including ABS).

- B (Body): “B” codes relate to the body systems, which are primarily components located within the passenger compartment. This can include systems like power windows, airbags, central locking, and interior lighting.

- U (Network or Undefined): “U” codes indicate communication or network issues. These codes pertain to problems with the vehicle’s internal communication networks, such as the Controller Area Network (CAN) bus, which allows various electronic control units to communicate with each other.

2. Second Character: Code Type (Digit)

The second character is a digit, usually ‘0’ or ‘1’, and it denotes whether the code is a standardized, generic code or a manufacturer-specific code.

- 0 (Generic or Standardized): A ‘0’ in the second position indicates a generic SAE code. These codes are standardized across all OBD-II compliant vehicles, regardless of manufacturer. This means that P0XXX, C0XXX, B0XXX, and U0XXX codes are universally defined and understood.

- 1 (Manufacturer-Specific): A ‘1’ in the second position signals a manufacturer-specific code (e.g., P1XXX, C1XXX, B1XXX, U1XXX). These codes are defined by individual vehicle manufacturers to address issues unique to their makes and models, or to provide more detailed diagnostics beyond the generic codes. These are often more complex to interpret without manufacturer-specific resources.

- 2 or 3 (Reserved for Future/Manufacturer Specific): While less common, ‘2’ or ‘3’ in this position often also indicate manufacturer-specific codes. The exact meaning can be nuanced and depends on the preceding letter and the specific manufacturer’s documentation. In most cases, encountering a ‘2’ or ‘3’ suggests a manufacturer-defined code.

3. Third Character: Subsystem (Digit)

The third character is a digit ranging from ‘1’ to ‘8’, specifying the particular subsystem within the broader system category (indicated by the first character) that is experiencing the fault.

- 1: Fuel and Air Metering System: Relates to issues with fuel delivery, air intake, and the mixture of fuel and air in the engine.

- 2: Fuel and Air Metering Injection System: Specifically points to problems within the fuel injection system.

- 3: Ignition System or Misfire: Indicates faults in the ignition system, including spark plugs, ignition coils, or misfires.

- 4: Auxiliary Emission Controls System: Concerns issues with emission control systems beyond the catalytic converter, such as EGR (Exhaust Gas Recirculation) or secondary air injection.

- 5: Vehicle Speed Controls, Idle Control System: Relates to systems controlling vehicle speed and engine idle speed.

- 6: Computer Output Circuit: Indicates a problem in the output circuit of the vehicle’s computer or control module.

- 7: Transmission: Points to transmission-related issues when the first character is ‘P’ (Powertrain).

- 8: Transmission: Also indicates transmission-related issues, often used for different types of transmission faults than ‘7’.

4 & 5. Fourth and Fifth Characters: Fault Index (Two Digits)

The fourth and fifth characters are digits, read together as a two-digit number ranging from 00 to 99. This two-digit number is the specific fault index. It precisely identifies the particular component or circuit within the subsystem (defined by the third character) that is malfunctioning. For instance, within the “Fuel and Air Metering System” (third character ‘1’), a fault index might specify a particular sensor, circuit, or condition.

To accurately understand the complete meaning of a DTC, it’s essential to consult a reliable OBD-II code database, your vehicle’s repair manual, or a professional diagnostic tool. These resources provide detailed explanations for each specific fault index in conjunction with the preceding characters.

Interpreting a DTC: An Example

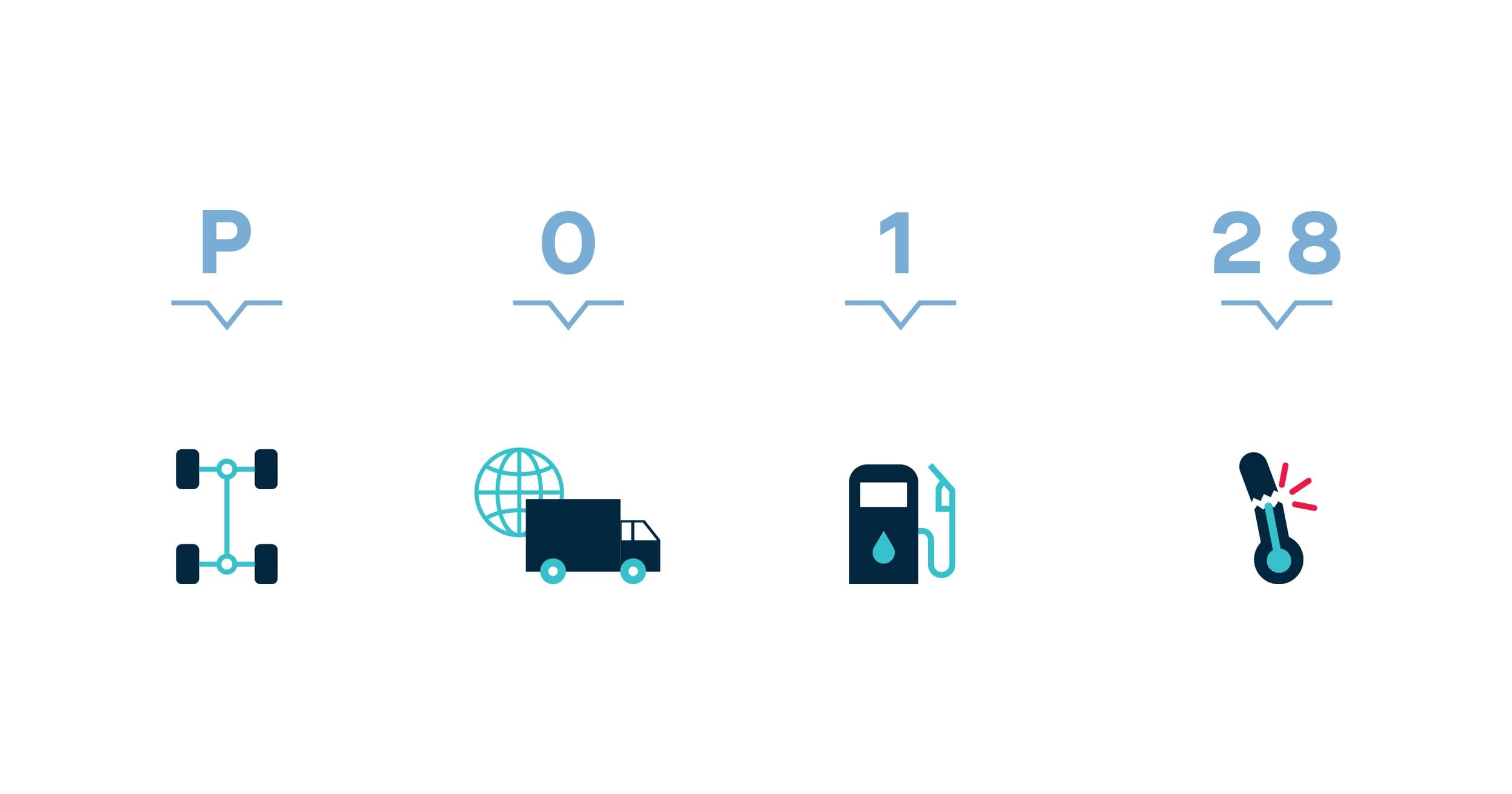

Let’s take a common DTC example: P0128 – “Coolant Thermostat (Coolant Temperature Below Thermostat Regulating Temperature)”. Let’s break down how to interpret this code character by character based on our understanding of what characters make up a basic OBD-II code:

- P: Indicates the fault is in the Powertrain system, meaning it’s related to the engine, transmission, or related components.

- 0: Signifies this is a generic, standardized SAE code, not manufacturer-specific.

- 1: Tells us the issue is within the Fuel and Air Metering System. While seemingly counterintuitive for a coolant issue, in the broader context of engine management, coolant temperature is crucial for fuel and air mixture calculations.

- 28: The fault index ’28’ specifically pinpoints the issue as “Coolant Thermostat (Coolant Temperature Below Thermostat Regulating Temperature)”. This means the engine coolant is not reaching the expected operating temperature within a reasonable time, often due to a stuck-open thermostat.

Therefore, by understanding the structure of the OBD-II code and what characters a basic OBD-II code is made up of, we can systematically decipher the meaning of DTCs and gain valuable insight into vehicle problems.

Common OBD-II DTCs

While there are thousands of possible DTCs, some are more frequently encountered than others. Here are a few examples of common OBD-II DTCs and their general meanings:

- P0442: Evaporative Emission Control System Leak Detected (Small Leak): Indicates a small leak in the evaporative emissions system, which prevents fuel vapor from escaping into the atmosphere.

- P0606: PCM/ECM Processor Fault: Signals a malfunction within the Powertrain Control Module (PCM) or Engine Control Module (ECM), the vehicle’s main computer.

- P0101: Mass Air Flow (MAF) Sensor Circuit Range/Performance Problem: Points to an issue with the MAF sensor, which measures the amount of air entering the engine.

- P0110: Intake Air Temperature Sensor Circuit Malfunction: Indicates a problem with the intake air temperature sensor circuit.

- P0500: Vehicle Speed Sensor Malfunction: Signals a fault with the vehicle speed sensor.

- P0706: Transmission Range Sensor Circuit Range/Performance: Indicates an issue with the transmission range sensor, which tells the computer what gear the transmission is in.

It’s important to remember that while DTCs are incredibly helpful in identifying a potential malfunction, they don’t always reveal the root cause. Further diagnosis by a qualified mechanic is often needed to pinpoint the exact cause of the problem and perform the necessary repairs.

J1939 DTCs: A Different Structure

While this article primarily focuses on OBD-II DTCs and what characters make up a basic OBD-II code, it’s worth briefly noting J1939 DTCs, which are prevalent in heavy-duty vehicles. J1939 DTCs have a different structure, comprising four fields:

- Suspect Parameter Number (SPN): A numerical code representing the specific parameter or component with the error.

- Failure Mode Identifier (FMI): A code indicating the type of error, such as a high or low voltage, short circuit, or calibration error.

- Occurrence Counter (OC): A counter tracking how many times the error has occurred.

- SPN Conversion Method (CM): Specifies the data format within the DTC message.

Understanding J1939 DTCs requires consulting J1939 documentation and specialized diagnostic tools designed for heavy-duty vehicles.

Telematics Solutions for DTC Management

For fleet managers overseeing numerous vehicles, manually scanning for DTCs can be time-consuming and inefficient. Telematics solutions, like those offered by Autel France, offer a streamlined approach to DTC management. Telematics devices plug into the vehicle’s OBD-II or J1939 port and wirelessly transmit vehicle data, including DTCs, to a central platform.

This allows fleet managers to:

- Remotely monitor vehicle health: Receive instant notifications of DTCs as they occur.

- Quickly diagnose issues: Understand the nature of the problem based on the DTC description without physically accessing the vehicle.

- Proactively schedule maintenance: Address potential problems early, minimizing downtime and repair costs.

- Filter and prioritize alerts: Focus on critical DTCs that require immediate attention.

By leveraging telematics, fleet operations can significantly enhance vehicle maintenance efficiency and reduce the impact of vehicle malfunctions.

Conclusion: Decoding Your Vehicle’s Language

Understanding what characters a basic OBD-II code is made up of empowers vehicle owners and fleet managers to take a more informed and proactive approach to vehicle maintenance. DTCs are not just random codes; they are structured messages providing valuable diagnostic information. While a DTC provides a starting point, remember that professional diagnosis is often necessary to pinpoint the root cause and implement effective repairs. By understanding the basics of DTCs, you can better communicate with mechanics, make informed decisions about vehicle repairs, and ultimately keep your vehicles running smoothly and efficiently.