65 Tire Pressure Vcds issues can be frustrating, causing warning lights and potentially affecting your vehicle’s performance. This comprehensive guide, brought to you by CARDIAGTECH.NET, dives deep into diagnosing and resolving these problems, offering solutions to get your Tire Pressure Monitoring System (TPMS) back on track. We will discuss common causes, troubleshooting steps, and how VCDS can help you pinpoint the issue, ultimately ensuring optimal tire health and safety. Proper tire inflation and TPMS function contribute to fuel efficiency and safe driving, making this a critical system to maintain.

1. Understanding Tire Pressure Monitoring Systems (TPMS)

A Tire Pressure Monitoring System, or TPMS, is a crucial safety feature in modern vehicles. Its primary function is to monitor the air pressure inside your tires and alert you when it falls significantly below the recommended level. This is usually indicated by a warning light on your dashboard. TPMS helps prevent accidents caused by underinflated tires, improves fuel efficiency, and extends tire life. According to the National Highway Traffic Safety Administration (NHTSA), TPMS has significantly reduced the number of accidents related to tire failure.

1.1 Types of TPMS Technology

There are two main types of TPMS: direct and indirect.

- Direct TPMS: Uses pressure sensors inside each tire to measure air pressure directly. These sensors transmit real-time pressure data to the vehicle’s computer.

- Indirect TPMS: Relies on the vehicle’s Anti-lock Braking System (ABS) wheel speed sensors to monitor tire pressure. It detects underinflation by comparing the rotational speed of each tire; an underinflated tire will have a slightly smaller diameter and rotate faster than properly inflated ones.

Understanding which type of TPMS your vehicle uses is vital for accurate diagnosis and repair. Direct TPMS offers more precise pressure readings, while indirect TPMS is generally less expensive and easier to maintain.

1.2 Why Accurate Tire Pressure Matters

Maintaining correct tire pressure is essential for several reasons:

- Safety: Underinflated tires can overheat, leading to tire failure and accidents. According to the NHTSA, underinflation is a leading cause of tire-related crashes.

- Fuel Efficiency: Properly inflated tires reduce rolling resistance, improving fuel economy. The U.S. Department of Energy estimates that you can improve your gas mileage by up to 3% by keeping your tires inflated to the correct pressure.

- Tire Life: Underinflation causes uneven wear, reducing the lifespan of your tires.

- Handling: Correct tire pressure ensures optimal handling and braking performance.

Regularly checking and maintaining your tire pressure is a simple yet effective way to enhance safety, save money, and prolong the life of your tires. The correct tire pressure for your vehicle can typically be found on a sticker inside the driver’s side doorjamb or in your owner’s manual.

1.3 VCDS and TPMS: A Powerful Combination

VCDS (VAG-COM Diagnostic System) is a powerful diagnostic tool used for Volkswagen, Audi, Skoda, and SEAT vehicles. It allows you to access and diagnose various electronic control units (ECUs) within your car, including the TPMS. With VCDS, you can:

- Read TPMS fault codes

- Monitor real-time tire pressure data

- Perform TPMS adaptations and calibrations

- Diagnose sensor issues

- Reset the TPMS after tire rotations or replacements

Using VCDS in conjunction with a good understanding of TPMS principles can significantly speed up the troubleshooting process and help you accurately identify and resolve TPMS-related issues. CARDIAGTECH.NET offers a wide range of VCDS tools and resources to help you get the most out of your TPMS diagnostics.

2. Identifying “65 Tire Pressure” TPMS Faults with VCDS

When diagnosing TPMS issues with VCDS, you’ll often encounter fault codes related to the “65 Tire Pressure” module. This section will help you understand what these codes mean and how to interpret them.

2.1 Decoding Common “65 Tire Pressure” VCDS Fault Codes

Several fault codes can appear under the “65 Tire Pressure” module in VCDS. Here are some of the most common ones:

| Fault Code | Description | Possible Causes |

|---|---|---|

| 8398082 (C111A) | Tire Pressure Sensor(s) – No Signal | Dead or faulty sensor, sensor not programmed, wiring issue, TPMS module malfunction, radio frequency interference. |

| 8401152 (C105C) | Radio Frequency Interference | External interference, faulty TPMS module, damaged wiring. |

| 00071 (0047) | Tire Pressure Monitoring System (TPMS) Control Module – No Signal/Communication | Wiring issue, faulty TPMS module, CAN bus problem. |

| 01390 | Tire Pressure Warning Switch (E492) | Faulty switch, wiring issue, incorrect coding. |

| 00042 (002A) | Tire Pressure Sensor; Rear Right (G224) | Faulty sensor, dead battery, sensor not programmed, wiring issue. |

It’s important to note that these are just a few examples, and the specific fault code you encounter may vary depending on your vehicle’s make, model, and year. Consulting the Ross-Tech Wiki or CARDIAGTECH.NET’s resources can provide more detailed information on specific fault codes.

2.2 Understanding Freeze Frame Data

VCDS fault codes often come with “Freeze Frame” data, which provides a snapshot of the vehicle’s conditions when the fault occurred. This data can be invaluable in diagnosing intermittent problems. Key information in the Freeze Frame data includes:

- Fault Status: Indicates whether the fault is currently present or intermittent.

- Fault Priority: Shows the severity of the fault (e.g., a high priority fault indicates a critical issue).

- Fault Frequency: Indicates how many times the fault has occurred.

- Reset Counter: The number of times the fault memory has been cleared.

- Mileage: The vehicle’s mileage when the fault occurred.

- Date and Time: The date and time the fault occurred.

- Vehicle Speed: The vehicle’s speed when the fault occurred.

- Outside Temperature: The ambient temperature when the fault occurred.

- Reception Level: The signal strength from the TPMS sensors.

Analyzing this data can help you determine if the fault is related to specific driving conditions or environmental factors. For example, if a “No Signal” fault occurs only at high speeds, it could indicate a problem with radio frequency interference or a weak sensor signal.

2.3 Example Diagnosis Using VCDS Data

Let’s consider an example based on the provided data:

Fault Code: 8398082 – Tire Pressure Sensor(s) C111A 31 [009] – No Signal Confirmed – Tested Since Memory Clear

Freeze Frame Data:

- Fault Status: 00000001

- Fault Priority: 3

- Fault Frequency: 1

- Reset counter: 145

- Mileage: 72336 km

- Date: 2022.03.18

- Time: 16:20:10

Analysis:

- The fault code indicates a “No Signal” issue with the tire pressure sensors.

- The “Confirmed” status suggests the problem is currently present.

- The fault priority of 3 indicates a moderate level of concern.

- The mileage and date/time data provide context for when the issue first arose.

Possible Causes:

Based on this information, possible causes could include:

- A dead or faulty TPMS sensor

- A sensor that needs to be reprogrammed to the vehicle

- Radio frequency interference

- A wiring issue between the sensor and the TPMS module

Next Steps:

- Use VCDS to check the individual sensor readings and signal strength.

- Verify that the sensors are correctly programmed to the vehicle.

- Inspect the wiring and connections for any damage or corrosion.

- Rule out potential sources of radio frequency interference.

By carefully analyzing the fault codes and Freeze Frame data, you can narrow down the potential causes and take targeted steps to resolve the TPMS issue. CARDIAGTECH.NET offers expert advice and support to help you interpret VCDS data and troubleshoot complex automotive problems.

TPMS sensor

TPMS sensor

3. Step-by-Step Troubleshooting Guide for TPMS Issues

This section provides a detailed, step-by-step guide to help you troubleshoot TPMS issues, particularly those related to the “65 Tire Pressure” module.

3.1 Preliminary Checks and Visual Inspection

Before diving into VCDS diagnostics, start with these preliminary checks:

- Tire Pressure: Manually check the tire pressure in all four tires using a reliable tire pressure gauge. Compare the readings to the recommended pressure on the doorjamb sticker. Adjust the pressure as needed.

- Visual Inspection: Inspect the tires for any signs of damage, such as cuts, bulges, or uneven wear. Check the TPMS sensor stems for damage or corrosion.

- Warning Light: Note the behavior of the TPMS warning light. Is it constantly on, flashing, or intermittent? This can provide clues about the nature of the problem.

- Recent Tire Service: If you recently had your tires rotated, replaced, or repaired, ensure that the TPMS sensors were properly installed and programmed.

These simple checks can often reveal obvious issues that might be causing the TPMS fault.

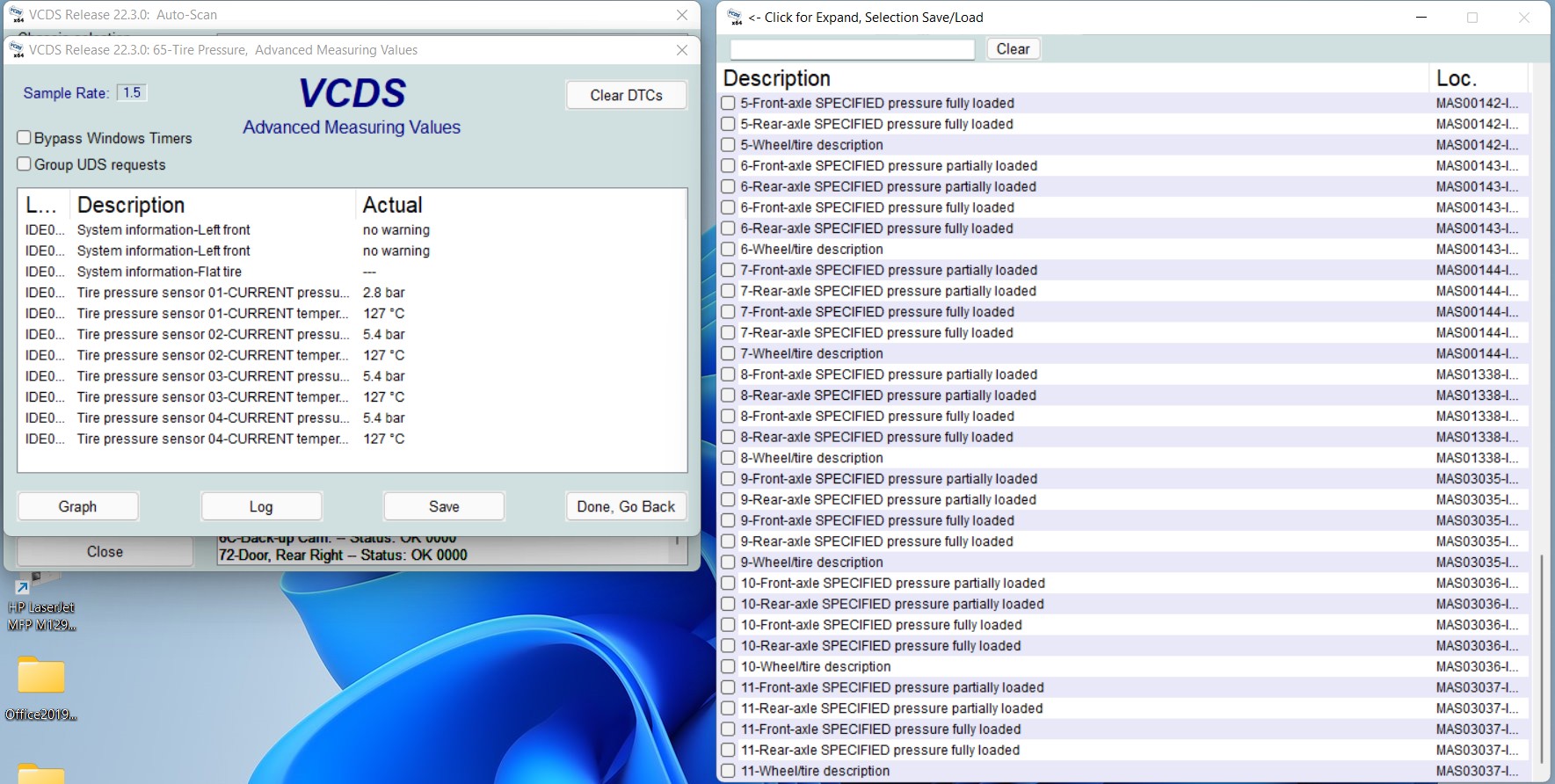

3.2 Using VCDS to Read TPMS Data

- Connect VCDS: Connect your VCDS interface to the vehicle’s OBD-II port and turn on the ignition.

- Select Control Module: Open VCDS software and select “Select Control Module.”

- Access TPMS Module: Choose “65 – Tire Pressure” from the list of control modules.

- Read Fault Codes: Click on “Fault Codes – 02” to view any stored fault codes. Record the fault codes and Freeze Frame data.

- Live Data: Select “Measuring Blocks – 08” to view real-time TPMS data. Pay attention to the following:

- Tire pressure readings for each sensor

- Sensor status (e.g., active, inactive, error)

- Sensor battery voltage (if available)

- Signal strength for each sensor

Analyzing the live data can help you identify faulty sensors, communication problems, or low battery voltage.

3.3 Diagnosing Sensor Issues

- Identify Faulty Sensor: If a specific sensor is showing an error or no signal in the live data, it’s likely the culprit.

- Check Sensor Battery: If your TPMS uses direct sensors, VCDS may be able to display the sensor battery voltage. A low voltage reading indicates a dead or dying battery.

- Sensor Activation: Some TPMS sensors need to be “woken up” after a period of inactivity. Follow the manufacturer’s recommended procedure for sensor activation. This usually involves driving the vehicle for a short distance.

- Sensor Programming: If you recently replaced a TPMS sensor, it may need to be programmed to the vehicle’s TPMS module. VCDS can be used to program new sensors. Refer to the VCDS documentation or CARDIAGTECH.NET’s resources for specific programming instructions.

3.4 Addressing Communication Problems

- Wiring Inspection: Check the wiring and connections between the TPMS sensors and the TPMS module for any signs of damage, corrosion, or loose connections. Pay particular attention to the antenna wiring, as this can affect signal reception.

- Radio Frequency Interference: Identify potential sources of radio frequency interference, such as aftermarket electronic devices, radar detectors, or mobile phone chargers. Try moving or removing these devices to see if it resolves the issue.

- TPMS Module: If you suspect a problem with the TPMS module itself, try performing a reset or adaptation using VCDS. If the module is faulty, it may need to be replaced.

- CAN Bus Issues: In some cases, TPMS communication problems can be caused by issues with the vehicle’s CAN bus network. Check for any other fault codes related to CAN bus communication.

3.5 Clearing Fault Codes and Testing

- Clear Fault Codes: After addressing the underlying issue, use VCDS to clear the TPMS fault codes.

- Test Drive: Take the vehicle for a test drive to see if the TPMS warning light remains off and the system functions correctly. Monitor the TPMS data using VCDS to ensure that all sensors are reporting accurate pressure readings.

- Re-scan: After the test drive, re-scan the TPMS module for any new fault codes.

If the TPMS warning light returns or new fault codes appear, repeat the troubleshooting steps to identify and resolve the remaining issues.

4. Advanced VCDS Functions for TPMS Calibration and Adaptation

VCDS offers several advanced functions that can be useful for TPMS calibration and adaptation. These functions allow you to fine-tune the TPMS settings and ensure accurate operation.

4.1 Performing TPMS Adaptations

TPMS adaptation is the process of teaching the TPMS module the unique IDs of the TPMS sensors. This is necessary when:

- Replacing TPMS sensors

- Rotating tires

- Installing a new TPMS module

The adaptation procedure varies depending on the vehicle make, model, and year. However, the general steps are as follows:

- Connect VCDS to the vehicle and access the “65 Tire Pressure” module.

- Select “Adaptation – 10.”

- Choose the appropriate adaptation channel (e.g., “Tire Pressure Sensor IDs”).

- Follow the on-screen instructions to enter the sensor IDs. These IDs can usually be found on the sensors themselves or in the sensor documentation.

- Save the adaptation data.

Some vehicles may require a specific driving cycle after the adaptation procedure to complete the learning process. Refer to the VCDS documentation or CARDIAGTECH.NET’s resources for detailed instructions.

4.2 Adjusting TPMS Thresholds

Some TPMS systems allow you to adjust the pressure thresholds that trigger the warning light. This can be useful if you are using tires with different pressure requirements or if you want to customize the sensitivity of the system.

To adjust the TPMS thresholds:

- Connect VCDS to the vehicle and access the “65 Tire Pressure” module.

- Select “Adaptation – 10.”

- Choose the adaptation channel for the desired threshold (e.g., “Low Pressure Warning Threshold”).

- Enter the new threshold value. Be sure to use the correct units (e.g., PSI or kPa).

- Save the adaptation data.

It’s important to note that adjusting the TPMS thresholds can affect the accuracy and reliability of the system. Always consult the vehicle manufacturer’s recommendations before making any changes.

4.3 Recoding the TPMS Module

In some cases, you may need to recode the TPMS module if you are changing the vehicle’s configuration or retrofitting new components. Recoding involves changing the coding value of the TPMS module to reflect the new configuration.

To recode the TPMS module:

- Connect VCDS to the vehicle and access the “65 Tire Pressure” module.

- Select “Coding – 07.”

- Enter the new coding value. The correct coding value will depend on the vehicle’s specific configuration. Consult the VCDS documentation or CARDIAGTECH.NET’s resources for the appropriate coding value.

- Save the coding data.

Incorrect coding can cause the TPMS to malfunction or not function at all. Always double-check the coding value before saving it.

4.4 When to Seek Professional Help

While VCDS can be a powerful tool for TPMS diagnostics and calibration, some issues may require professional expertise. Consider seeking help from a qualified mechanic if:

- You are not comfortable working with VCDS or performing advanced adaptations.

- You are unable to diagnose the TPMS issue after following the troubleshooting steps.

- You suspect a problem with the TPMS module or the vehicle’s CAN bus network.

- You are experiencing persistent TPMS problems despite your best efforts.

CARDIAGTECH.NET can connect you with experienced automotive technicians who can provide expert TPMS diagnostics and repair services.

5. Maintaining Your TPMS for Optimal Performance

Maintaining your TPMS is essential for ensuring its continued accuracy and reliability. Here are some tips for keeping your TPMS in top condition:

5.1 Regular Tire Pressure Checks

Check your tire pressure at least once a month and before any long trips. Use a reliable tire pressure gauge and adjust the pressure as needed. Remember to check the pressure when the tires are cold, as the pressure increases as the tires warm up.

5.2 Proper Tire Inflation Practices

Always inflate your tires to the recommended pressure on the doorjamb sticker. Avoid overinflation or underinflation, as both can negatively affect tire life, handling, and fuel efficiency.

5.3 TPMS Sensor Maintenance

- Sensor Stem Caps: Use the correct TPMS sensor stem caps to protect the sensor stems from dirt, moisture, and corrosion.

- Sensor Replacement: Replace TPMS sensors when they reach the end of their service life (typically 5-7 years) or when the battery is dead.

- Professional Installation: Have TPMS sensors installed and programmed by a qualified mechanic to ensure proper operation.

5.4 Addressing TPMS Warnings Promptly

If the TPMS warning light comes on, don’t ignore it. Check your tire pressure immediately and address any issues. Driving on underinflated tires can be dangerous and can damage your tires.

5.5 Avoiding Common TPMS Problems

- Corrosion: Protect TPMS sensors from corrosion by using the correct stem caps and avoiding harsh chemicals.

- Physical Damage: Be careful when mounting and dismounting tires to avoid damaging the TPMS sensors.

- Aftermarket Products: Avoid using aftermarket tire sealants or inflators that can damage TPMS sensors.

By following these maintenance tips, you can keep your TPMS functioning properly and ensure your safety on the road.

6. Real-World Case Studies: Resolving “65 Tire Pressure” Faults

This section presents real-world case studies of TPMS issues related to the “65 Tire Pressure” module, showcasing how VCDS can be used to diagnose and resolve these problems.

6.1 Case Study 1: Intermittent “No Signal” Fault

Vehicle: 2016 Volkswagen Golf

Problem: The customer reported that the TPMS warning light would come on intermittently, especially at higher speeds. VCDS showed the following fault code:

- 8398082 – Tire Pressure Sensor(s) C111A 31 [009] – No Signal Confirmed – Tested Since Memory Clear

Diagnosis:

- The technician used VCDS to check the live TPMS data. All four sensors were initially reporting pressure readings, but the signal strength for the front left sensor was significantly lower than the others.

- The technician inspected the wiring and connections for the front left sensor and found a loose connection.

Solution:

- The technician resecured the connection for the front left sensor.

- The technician cleared the fault codes and took the vehicle for a test drive. The TPMS warning light remained off, and the signal strength for all sensors was now within the normal range.

Outcome:

The intermittent “No Signal” fault was resolved by addressing the loose connection. This case study highlights the importance of checking wiring and connections when troubleshooting TPMS issues.

6.2 Case Study 2: TPMS Failure After Tire Rotation

Vehicle: 2018 Audi A4

Problem: The customer reported that the TPMS warning light came on immediately after having their tires rotated. VCDS showed the following fault codes:

- 00071 (0047) – Tire Pressure Monitoring System (TPMS) Control Module – No Signal/Communication

- 00042 (002A) – Tire Pressure Sensor; Rear Right (G224)

Diagnosis:

- The technician suspected that the tire rotation had disrupted the TPMS sensor IDs.

- The technician used VCDS to check the TPMS adaptation data. The sensor IDs were incorrect.

Solution:

- The technician used VCDS to perform a TPMS adaptation, entering the correct sensor IDs for each tire.

- The technician cleared the fault codes and took the vehicle for a test drive. The TPMS warning light remained off, and the system functioned correctly.

Outcome:

The TPMS failure was resolved by performing a TPMS adaptation after the tire rotation. This case study emphasizes the need to re-adapt the TPMS sensors after any tire service that involves changing their positions.

6.3 Case Study 3: Dead TPMS Sensor Battery

Vehicle: 2015 Volkswagen Passat

Problem: The customer reported that the TPMS warning light was constantly on. VCDS showed the following fault code:

- 8398082 – Tire Pressure Sensor(s) C111A 31 [009] – No Signal Confirmed – Tested Since Memory Clear

Diagnosis:

- The technician used VCDS to check the live TPMS data. One of the sensors was not reporting any pressure readings.

- VCDS also showed a low battery voltage for the non-reporting sensor.

Solution:

- The technician replaced the dead TPMS sensor with a new one.

- The technician used VCDS to program the new sensor to the vehicle.

- The technician cleared the fault codes and took the vehicle for a test drive. The TPMS warning light remained off, and the system functioned correctly.

Outcome:

The TPMS issue was resolved by replacing the dead sensor. This case study highlights the importance of monitoring sensor battery voltage and replacing sensors when they reach the end of their service life.

These case studies demonstrate how VCDS can be used to diagnose and resolve a variety of TPMS issues. By following a systematic troubleshooting approach and utilizing VCDS’s diagnostic capabilities, you can effectively maintain your TPMS and ensure optimal performance.

7. Choosing the Right Tools for TPMS Diagnostics and Repair

Having the right tools is essential for effective TPMS diagnostics and repair. Here are some of the key tools you’ll need:

7.1 VCDS Interface

A VCDS interface is the core tool for accessing and diagnosing the TPMS module. CARDIAGTECH.NET offers a wide range of VCDS interfaces to suit different needs and budgets. When choosing a VCDS interface, consider the following factors:

- Compatibility: Ensure that the interface is compatible with your vehicle’s make, model, and year.

- Features: Look for an interface that supports all the necessary TPMS functions, such as fault code reading, live data monitoring, adaptation, and coding.

- Software Updates: Choose an interface that comes with regular software updates to ensure compatibility with the latest vehicle models and diagnostic protocols.

7.2 TPMS Sensor Programming Tool

A TPMS sensor programming tool is necessary for programming new TPMS sensors to the vehicle. These tools can read sensor IDs, program new IDs, and perform TPMS adaptations. When selecting a TPMS sensor programming tool, consider the following:

- Compatibility: Ensure that the tool is compatible with the TPMS sensors you are using.

- Ease of Use: Look for a tool with a user-friendly interface and clear instructions.

- Update Capability: Choose a tool that can be updated with the latest sensor protocols and vehicle information.

7.3 Tire Pressure Gauge

A reliable tire pressure gauge is essential for checking and adjusting tire pressure. Choose a gauge that is accurate, easy to read, and durable.

7.4 Tire Repair Tools

If you need to repair a tire, you’ll need a variety of tire repair tools, such as:

- Tire levers

- Tire patch kit

- Tire inflator

7.5 Multimeter

A multimeter can be used to check wiring continuity and voltage, which can be helpful when diagnosing TPMS communication problems.

CARDIAGTECH.NET offers a comprehensive selection of high-quality TPMS diagnostic and repair tools. Contact us today to find the right tools for your needs.

8. Common Mistakes to Avoid When Working with TPMS

Working with TPMS can be tricky, and it’s easy to make mistakes if you’re not careful. Here are some common mistakes to avoid:

8.1 Ignoring TPMS Warnings

Ignoring TPMS warnings can lead to serious safety consequences. Always check your tire pressure immediately when the TPMS warning light comes on.

8.2 Overinflating or Underinflating Tires

Overinflating or underinflating tires can negatively affect tire life, handling, and fuel efficiency. Always inflate your tires to the recommended pressure on the doorjamb sticker.

8.3 Using Incorrect TPMS Sensors

Using incorrect TPMS sensors can cause the system to malfunction or not function at all. Always use sensors that are specifically designed for your vehicle.

8.4 Improper Sensor Installation

Improper sensor installation can damage the sensors or cause them to malfunction. Always have TPMS sensors installed and programmed by a qualified mechanic.

8.5 Neglecting Sensor Maintenance

Neglecting sensor maintenance can shorten the lifespan of the sensors and lead to TPMS problems. Follow the maintenance tips outlined in Section 5 to keep your TPMS sensors in top condition.

8.6 Forgetting to Re-adapt Sensors After Tire Service

Forgetting to re-adapt sensors after tire service (such as tire rotations or replacements) can cause the TPMS to malfunction. Always perform a TPMS adaptation after any tire service that involves changing the positions of the sensors.

By avoiding these common mistakes, you can ensure that your TPMS functions properly and protects you from potential safety hazards.

9. The Future of TPMS Technology

TPMS technology is constantly evolving, with new features and capabilities being introduced all the time. Here are some trends to watch for in the future of TPMS:

9.1 More Advanced Sensors

Future TPMS sensors may include additional capabilities, such as:

- Tire temperature monitoring

- Tire wear monitoring

- Automatic tire inflation

9.2 Integration with Vehicle Systems

TPMS data may be more closely integrated with other vehicle systems, such as:

- Adaptive cruise control

- Electronic stability control

- Automatic emergency braking

This integration could allow these systems to adjust their behavior based on tire pressure and temperature, further enhancing safety and performance.

9.3 Over-the-Air Updates

Future TPMS systems may be able to receive over-the-air software updates, allowing for new features and improvements to be added without the need for a trip to the mechanic.

9.4 Wireless Charging

TPMS sensors may eventually be powered by wireless charging, eliminating the need for batteries and extending the lifespan of the sensors.

9.5 Enhanced Diagnostics

Future TPMS diagnostic tools may offer more advanced features, such as:

- Predictive diagnostics that can anticipate potential TPMS problems before they occur

- Remote diagnostics that allow technicians to diagnose TPMS issues from a distance

As TPMS technology continues to advance, it will play an increasingly important role in ensuring vehicle safety and performance. Staying up-to-date on the latest TPMS developments will be essential for automotive technicians and enthusiasts alike.

10. Why Choose CARDIAGTECH.NET for Your TPMS Needs

CARDIAGTECH.NET is your trusted source for all things TPMS. We offer:

10.1 Wide Selection of TPMS Tools and Equipment

We carry a comprehensive selection of VCDS interfaces, TPMS sensor programming tools, and other TPMS diagnostic and repair equipment.

10.2 Expert Technical Support

Our team of experienced technicians can provide expert advice and support to help you diagnose and resolve TPMS issues.

10.3 Competitive Pricing

We offer competitive pricing on all of our TPMS products and services.

10.4 Fast Shipping

We offer fast shipping to get you the tools you need quickly.

10.5 Commitment to Quality

We are committed to providing our customers with the highest quality TPMS products and services.

Contact CARDIAGTECH.NET today to learn more about how we can help you with your TPMS needs. Our address is 276 Reock St, City of Orange, NJ 07050, United States. You can reach us via Whatsapp at +1 (641) 206-8880 or visit our website CARDIAGTECH.NET.

Experiencing challenges with your car’s tire pressure monitoring system? Don’t let these issues compromise your safety or fuel efficiency. Contact CARDIAGTECH.NET today for expert guidance and top-quality tools! Click on our Whatsapp button now and speak with one of our experts, or visit our website CARDIAGTECH.NET to explore our extensive range of diagnostic tools! Our address is 276 Reock St, City of Orange, NJ 07050, United States. You can also call us on Whatsapp at +1 (641) 206-8880.

Frequently Asked Questions (FAQ) About TPMS and VCDS

Here are some frequently asked questions about TPMS and VCDS:

- What is TPMS?

- TPMS stands for Tire Pressure Monitoring System. It’s an electronic system that monitors the air pressure inside your tires and alerts you when it falls below a certain level.

- What are the benefits of TPMS?

- TPMS helps prevent accidents caused by underinflated tires, improves fuel efficiency, and extends tire life.

- What are the two types of TPMS?

- Direct TPMS uses pressure sensors inside each tire, while indirect TPMS relies on the vehicle’s ABS wheel speed sensors.

- What is VCDS?

- VCDS (VAG-COM Diagnostic System) is a diagnostic tool used for Volkswagen, Audi, Skoda, and SEAT vehicles.

- How can VCDS help with TPMS diagnostics?

- VCDS can read TPMS fault codes, monitor real-time tire pressure data, perform TPMS adaptations and calibrations, diagnose sensor issues, and reset the TPMS.

- What are some common “65 Tire Pressure” VCDS fault codes?

- Common fault codes include “Tire Pressure Sensor(s) – No Signal,” “Radio Frequency Interference,” and “Tire Pressure Monitoring System (TPMS) Control Module – No Signal/Communication.”

- What is TPMS adaptation?

- TPMS adaptation is the process of teaching the TPMS module the unique IDs of the TPMS sensors.

- When do I need to perform TPMS adaptation?

- You need to perform TPMS adaptation when replacing TPMS sensors, rotating tires, or installing a new TPMS module.

- Can I adjust the TPMS thresholds?

- Some TPMS systems allow you to adjust the pressure thresholds that trigger the warning light. However, it’s important to consult the vehicle manufacturer’s recommendations before making any changes.

- When should I seek professional help for TPMS issues?

- You should seek professional help if you are not comfortable working with VCDS, are unable to diagnose the TPMS issue, suspect a problem with the TPMS module or CAN bus network, or are experiencing persistent TPMS problems.