When your car throws a check engine light, your first instinct as a savvy car owner or technician is to reach for your OBDII scanner. This invaluable tool should quickly plug into your vehicle and reveal the diagnostic trouble codes (DTCs) hiding within your car’s computer system. But what happens when you plug in, and nothing happens? The dreaded “Cant Communicate With Obdii” message can leave you stranded and scratching your head.

This guide is designed to walk you through the common culprits behind OBDII communication failures and provide you with practical troubleshooting steps. We’ll help you diagnose the issue, so you can get back to diagnosing your car’s actual problems.

Decoding the Silence: Common Causes of OBDII Communication Issues

Before you assume your car is having a major meltdown, let’s consider the more common and often simpler reasons why your OBDII scanner might be refusing to talk to your vehicle.

-

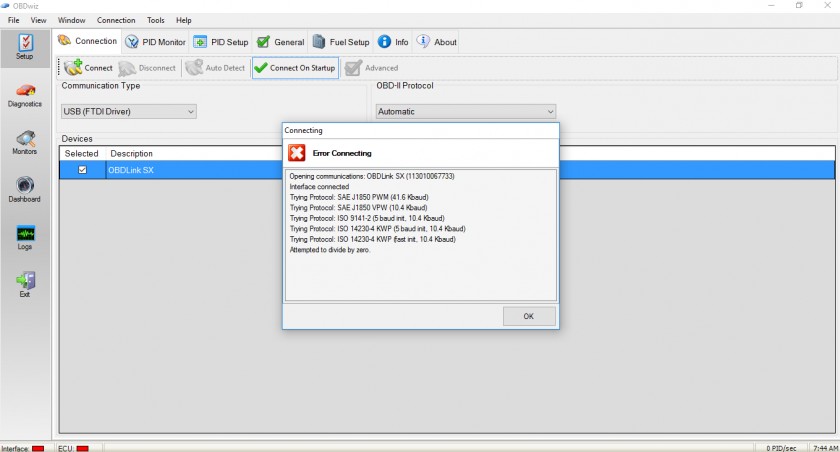

Faulty OBDII Scanner: Let’s start with the most straightforward possibility – the scanner itself. Just like any electronic device, OBDII scanners can malfunction. This could be due to internal hardware failures, corrupted software, or even simple wear and tear. Before diving deep into your car’s system, try your scanner on another vehicle if possible. If it fails there too, the scanner is likely the problem.

-

Damaged OBDII Port: The OBDII port, also known as the Data Link Connector (DLC), is your car’s gateway to diagnostics. Located typically under the dashboard on the driver’s side, this port can be physically damaged. Check for bent or broken pins inside the port, debris or corrosion buildup, or even a loose connection. A damaged port can prevent the scanner from making proper contact.

-

Wiring Problems in the OBDII Circuit: The OBDII port isn’t directly connected to your car’s computer by magic. Wires run from the port to the vehicle’s central computer, often the Powertrain Control Module (PCM) or Engine Control Module (ECM). These wires can become disconnected, frayed, or damaged over time, especially in harsh under-dash environments. Breaks in these wires interrupt the communication pathway.

-

Vehicle Battery Issues: The OBDII system, and indeed your car’s computer, relies on a stable power supply. A dead or significantly weakened car battery can prevent the PCM/ECM from powering up correctly or maintaining communication. Ensure your car battery is adequately charged and in good health. A weak battery can cause a multitude of electrical gremlins, including OBDII communication failures.

Step-by-Step Troubleshooting: Restoring OBDII Communication

If you’ve ruled out a faulty scanner and visually inspected the OBDII port, it’s time to get a little more hands-on with a multimeter. These tests will help you pinpoint electrical issues within the OBDII circuit.

Important Safety Note: Always consult your vehicle’s repair manual for specific wiring diagrams and component locations. When working with electrical systems, ensure the ignition is off and take necessary safety precautions.

TEST 1: Ground Circuit Integrity Check (DLC Pins 4 and 5)

This test verifies that the OBDII port has a good ground connection, which is crucial for proper communication.

-

Set your Digital Multimeter (DMM) to measure DC Voltage.

-

Connect the positive (red) lead of your DMM to DLC pin 4.

-

Connect the negative (black) lead of your DMM directly to the negative terminal of your car battery. Do not use a chassis ground for this test, as we are specifically checking the DLC ground circuit. You may need to use jumper wires to reach the battery terminal.

-

Turn the ignition ON (engine off).

-

Observe the voltage reading on your DMM.

- Expected Result: The voltage drop should be 0.1 Volts or less.

- Interpretation: A reading higher than 0.1V indicates excessive resistance in the ground circuit. This could be due to a poor ground connection at the battery, a corroded ground wire, or a fault within the wiring harness.

-

Repeat steps 2-5 for DLC pin 5. Pin 5 is also a ground pin and should yield similar results.

OBDII port and multimeter setup for ground test

OBDII port and multimeter setup for ground test

TEST 2: Data Pin Voltage Check (DLC Pin 2 – SAE J1850 PWM/VPW)

Note: Pin 2 is specific to SAE J1850 PWM/VPW communication protocols, commonly found in older Ford and GM vehicles. This test may not be applicable to all vehicles, especially modern CAN bus systems. Consult your vehicle’s wiring diagram.

This test checks if the PCM is attempting to transmit data on the designated data pin.

-

Keep your DMM set to DC Voltage.

-

Connect the positive (red) lead of your DMM to DLC pin 2.

-

Connect the negative (black) lead of your DMM to a known good ground. This can be DLC pin 4, pin 5 (from the previous test, if they passed), or a reliable chassis ground.

-

Turn the ignition ON (engine off).

-

Observe the voltage reading on your DMM.

- Expected Result: The voltage should be approximately 5V or fluctuate between 3.5V and 5.0V.

- Interpretation:

- 5V or fluctuating voltage: Indicates the PCM is likely attempting to communicate. If your scanner still fails, the issue might lie elsewhere, such as protocol incompatibility or scanner malfunction.

- 0V or very low voltage: Suggests the PCM is not transmitting data on this pin. This could be due to a problem with the PCM itself, a break in the wiring to pin 2, or a power supply issue to the PCM.

TEST 3: ECM/PCM Voltage Supply Check (DLC Battery + Terminal)

This test verifies that the PCM is receiving power. A blown fuse in the power supply circuit to the PCM can prevent communication.

-

Keep your DMM set to DC Voltage.

-

Connect the positive (red) lead of your DMM to the DLC Battery + terminal (consult your vehicle’s wiring diagram to identify the Battery + pin – often pin 16).

-

Connect the negative (black) lead of your DMM to the negative terminal of your car battery.

-

Turn the ignition ON (engine off).

-

Observe the voltage reading on your DMM.

- Expected Result: The reading should be close to your battery voltage (e.g., 12V-14V).

- Interpretation: Significantly lower voltage or no voltage indicates a power supply problem to the PCM. Check the fuses related to the PCM and OBDII system (often labeled as “ECU,” “PCM,” “EFI,” or “diagnostic”). A common culprit is a blown lighter fuse, as it sometimes shares the same circuit.

TEST 4: DLC Bias Voltage Check (DLC Bias Terminals)

Note: This test is more advanced and may require your vehicle’s specific wiring diagram to identify bias terminals. Consult your repair manual.

This test checks the bias voltage on the communication bus lines.

- Keep your DMM set to DC Voltage.

- Identify the DLC bias terminals in your vehicle’s wiring diagram (often CAN High and CAN Low pins in modern vehicles).

- Connect the positive (red) lead of your DMM to one of the DLC bias terminals (e.g., CAN High).

- Connect the negative (black) lead of your DMM to a known good ground.

- Turn the ignition ON (engine off).

- Observe the voltage reading on your DMM.

- Expected Result (Ignition ON, No Bus Activity): One bias terminal (e.g., CAN High) should read approximately 0V, and the other (e.g., CAN Low) should read approximately 5V.

- Expected Result (Ignition ON, Bus Activity Present): With bus activity, the voltage on both bias terminals should vary between 0V and 5V. The fluctuation indicates data transmission.

- Interpretation: Incorrect or no bias voltages can indicate problems with the PCM, the wiring to the bias terminals, or issues within the communication network itself.

Further Investigation and Considerations

If you’ve performed these tests and are still facing “cant communicate with obdii,” here are some additional points to consider:

- Fuse Box Inspection: Thoroughly check all fuses related to the ECM/PCM, OBDII system, and related circuits. Use your vehicle’s owner’s manual or repair manual to locate the correct fuses. Replace any blown fuses with the correct amperage rating.

- PCM/ECM Issues: In rare cases, a faulty PCM/ECM itself can be the cause of communication problems. If all wiring and power supply checks out, and you suspect a PCM issue, professional diagnosis and potentially replacement may be necessary.

- Aftermarket Accessories: Sometimes, aftermarket accessories improperly installed or malfunctioning (e.g., alarms, remote starters, audio systems) can interfere with the OBDII system. Try disconnecting any recently installed aftermarket electronics to see if communication is restored.

Conclusion: Restoring Your Diagnostic Link

Dealing with an OBDII scanner that won’t communicate can be frustrating, but by systematically following these troubleshooting steps, you can often pinpoint the problem. Start with the simple checks like scanner functionality and port inspection, then move into electrical testing with a multimeter.

Remember, if you’re uncomfortable performing electrical tests or are unable to diagnose the issue yourself, it’s always best to consult a qualified automotive technician. They have specialized tools and expertise to quickly diagnose and repair complex OBDII communication problems, getting you back on the road with a functional diagnostic system.