Understanding OBDII code reader codes is crucial for efficient fleet management. These codes, generated by your vehicle’s onboard computer, provide valuable insights into the health of your vehicles, enabling proactive maintenance and minimizing downtime. This comprehensive guide delves into OBDII codes, their types, how to read and clear them, and strategies for effective fleet-wide management.

What OBD2 codes mean

What OBD2 codes mean

Understanding OBDII Codes and Their Importance

OBDII (On-Board Diagnostics II) codes are alphanumeric messages that illuminate potential issues within your vehicle’s systems. These codes arise when the onboard computer detects irregularities in data received from various components like the engine, transmission, and emissions system. An illuminated “Check Engine” light often accompanies these codes, signaling the need for further investigation using an OBDII code reader. This device, connecting to the OBDII port usually located under the dashboard, translates these codes into actionable information.

Types of OBDII Code Reader Codes

OBDII codes are categorized into four distinct types:

Powertrain Codes (P-Codes)

Powertrain codes relate to the engine, transmission, and drivetrain. For example, code P0101 indicates a problem with the Mass Air Flow (MAF) sensor, potentially impacting fuel efficiency and engine performance.

Body Codes (B-Codes)

Body codes pertain to issues within the vehicle’s body, such as airbags, lighting, and climate control. Code B0020, for instance, signifies a problem with the driver’s side airbag deployment circuit.

Chassis Codes (C-Codes)

Chassis codes address problems with the vehicle’s chassis systems, including brakes, steering, and suspension. Code C1234, for example, might point to a malfunctioning wheel speed sensor, potentially affecting stability and braking.

Network Communication Codes (U-Codes)

Network communication codes signal problems within the vehicle’s communication network. Code U0100, for instance, suggests a communication breakdown with the Engine Control Module (ECM), often due to a faulty battery.

Deciphering OBDII Codes: A Step-by-Step Guide

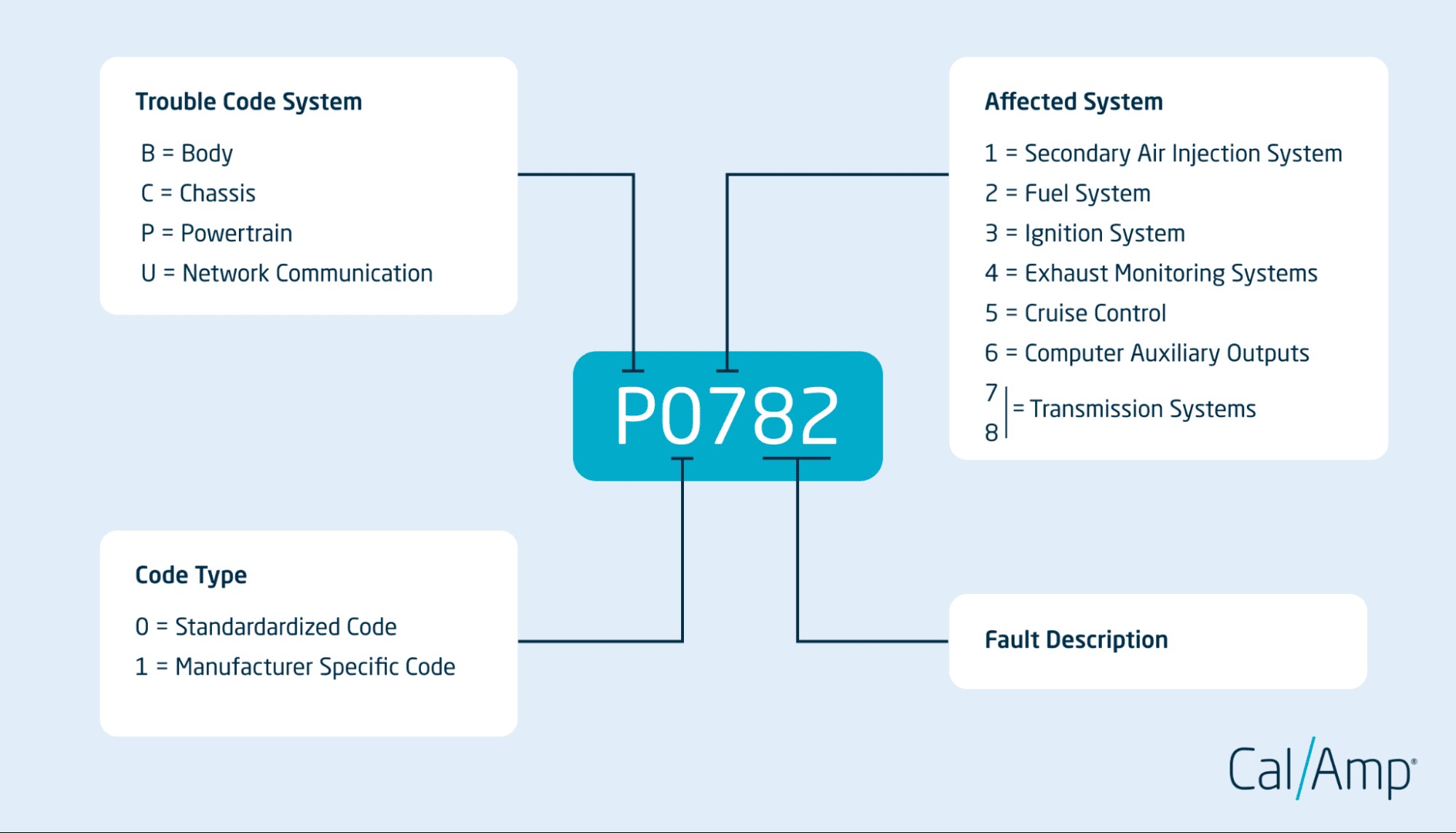

OBDII codes follow a standardized five-character format:

1. Trouble Code System (First Character)

The first character (a letter) indicates the system: P (Powertrain), B (Body), C (Chassis), or U (Network Communication).

2. Code Type (Second Character)

The second character (a number) denotes whether the code is generic (0) or manufacturer-specific (1).

3. Affected System (Third Character)

The third character (a number) specifies the affected subsystem (e.g., fuel system, ignition system).

4. Specific Code (Fourth and Fifth Characters)

The final two characters (numbers) pinpoint the specific problem within the subsystem.

Clearing OBDII Codes

While addressing the underlying issue is paramount, there are methods to clear OBDII codes:

1. Using an OBDII Scanner

An OBDII scanner can retrieve and clear Diagnostic Trouble Codes (DTCs).

2. Driving Through a Drive Cycle

Certain codes may clear automatically after completing a specific driving pattern defined by the manufacturer.

3. Consulting a Mechanic

A qualified mechanic possesses the expertise and tools to diagnose and resolve the underlying problem, ensuring proper code clearance.

Preventing OBDII Codes: Proactive Maintenance Strategies

Preventing OBDII codes requires proactive measures:

1. Regular Vehicle Maintenance

Adhering to a scheduled maintenance routine, including oil changes, fluid top-offs, and component inspections, can prevent many issues.

2. Using Quality Fuel and Fluids

Utilizing high-quality fuel and fluids ensures optimal engine performance and reduces the risk of component failure.

Streamlining OBDII Code Management for Fleets

Effective fleet management necessitates a streamlined approach to handling OBDII codes:

1. Centralized Code Tracking

Consolidating code data from all vehicles into a central system allows for comprehensive monitoring and analysis.

2. Continuous Fleet Monitoring

Real-time monitoring using telematics systems enables immediate detection of OBDII codes, facilitating prompt action.

3. Prioritizing Repairs Based on Severity

Categorizing codes by severity enables efficient resource allocation, ensuring critical issues are addressed first.

Conclusion

Mastering Can Obdii Code Reader Codes empowers fleet managers to make informed decisions, optimizing vehicle health, minimizing downtime, and enhancing overall operational efficiency. By implementing proactive maintenance strategies and leveraging technology for streamlined code management, fleet operations can achieve significant cost savings and improved performance.