The OBDII (On-Board Diagnostics II) port is a critical component for diagnosing car problems. However, for certain Toyota and Lexus models, connecting an OBDII scanner can inadvertently trigger issues with the Vehicle Stability Control (VSC) system. This article delves into the intricacies of the Obdii Pin Diagram, specifically focusing on the challenges encountered with early Toyota and Lexus vehicles and how to resolve them.

The OBDII Scanner Dilemma: Triggering Unintended Consequences

Many owners of older Toyota and Lexus vehicles have reported a recurring problem: connecting an OBDII scanner, even for a simple diagnostic check, can unexpectedly activate the VSC and Trac Off warning lights. This issue stems from the scanner’s interaction with the vehicle’s yaw sensor calibration.

Historically, OBDII communication has utilized various protocols. While scanners are designed to cycle through these protocols to establish communication, certain early Toyota and Lexus models are susceptible to misinterpretations. When a scanner connects using a newer protocol than the vehicle supports, it can mistakenly erase the stored yaw sensor calibration data, leading to illuminated warning lights.

This erasure necessitates a recalibration of the yaw sensor’s zero point, which is crucial for the VSC system to accurately detect skids and maintain vehicle stability. Without this calibration, the VSC and Trac systems are deactivated as a safety precaution. Simply resetting the vehicle’s computer won’t resolve the issue; the lights will reappear shortly after the vehicle begins moving.

Understanding the OBDII Pin Diagram and Protocol Variations

The root of this problem lies within the OBDII pin diagram and the varying protocols used for communication. Different protocols utilize different pins for specific functions. The critical pin in this scenario is the Ts (Transmission Signal) pin, responsible for transmitting data related to the yaw sensor.

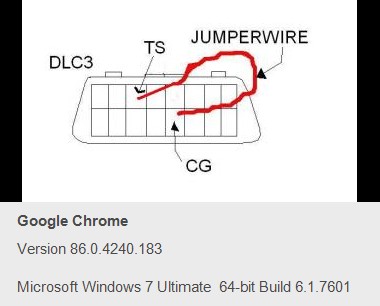

Confusion arises due to the existence of multiple OBDII pin diagrams for Toyota and Lexus vehicles, each showing a different location for the Ts pin. This discrepancy, coupled with the scanner’s potential to utilize an incompatible protocol, increases the risk of accidental data erasure. While the CG (Common Ground) pin remains consistent across diagrams, the varying location of the Ts pin complicates manual reset procedures. Incorrectly shorting pins can potentially damage the ECU, highlighting the need for accurate pin identification.

Solutions: Manual Reset vs. Specialized Scanners

There are two primary methods for re-establishing the zero point yaw sensor calibration:

-

Manual Reset: This involves shorting specific pins on the OBDII connector using a jumper wire while following a precise sequence of ignition on/off cycles. However, this method requires accurate identification of the Ts pin based on the vehicle’s specific OBDII pin diagram and protocol. Uncertainty regarding the Ts pin location makes this a risky procedure.

-

Electronic Reset: Specialized older aftermarket scanners or dealer-level diagnostic tools possess the capability to electronically reset the yaw sensor calibration. This method is generally safer and more reliable, avoiding the risks associated with manual pin shorting.

OBDII Protocols and Pin Identification

Identifying the correct OBDII protocol is crucial for determining the Ts pin location. Common protocols include:

- SAE J1850 VPW (Variable Pulse Width): Used by Ford.

- SAE J1850 PWM (Pulse Width Modulation): Used by General Motors.

- ISO 9141-2: Used by Asian, Chrysler, and European vehicles.

- ISO 14230-4 KWP2000 (Keyword Protocol 2000): Used by Asian vehicles.

- ISO 15765-4/SAE J2480 (CAN): Introduced in 2003 and widely adopted.

Determining the vehicle’s protocol and consulting the corresponding OBDII pin diagram is essential for a successful manual reset. One method to identify the CAN protocol involves measuring the resistance between pin 14 and pin 6 (positive 12V). A reading of 60 ohms suggests the presence of the CAN protocol.

Conclusion: Navigating the Complexities of OBDII in Older Vehicles

The interaction between OBDII scanners and early Toyota and Lexus models highlights the importance of understanding the underlying protocols and pin diagrams. While newer vehicles have standardized protocols, owners of older models should exercise caution when using OBDII scanners. The risk of inadvertently triggering VSC issues underscores the need for accurate pin identification and the potential benefits of using specialized diagnostic tools for resetting the yaw sensor calibration.