An illuminated check engine light or a dead battery can be frustrating. While a trip to the mechanic might seem inevitable, an Obdii Scanner With Alternator Check capabilities can often provide valuable insights into the problem, potentially saving you time and money. This guide explores how an OBDII scanner can help diagnose alternator issues, empowering you to troubleshoot your vehicle’s electrical system.

The Alternator’s Crucial Role

The alternator is the powerhouse of your vehicle’s electrical system. It generates electricity to power everything from headlights and radio to essential engine components. A malfunctioning alternator can lead to a drained battery, dimming lights, and even engine stalling. Recognizing the symptoms of a failing alternator is key to preventing unexpected breakdowns.

Can an OBDII Scanner Diagnose Alternator Problems?

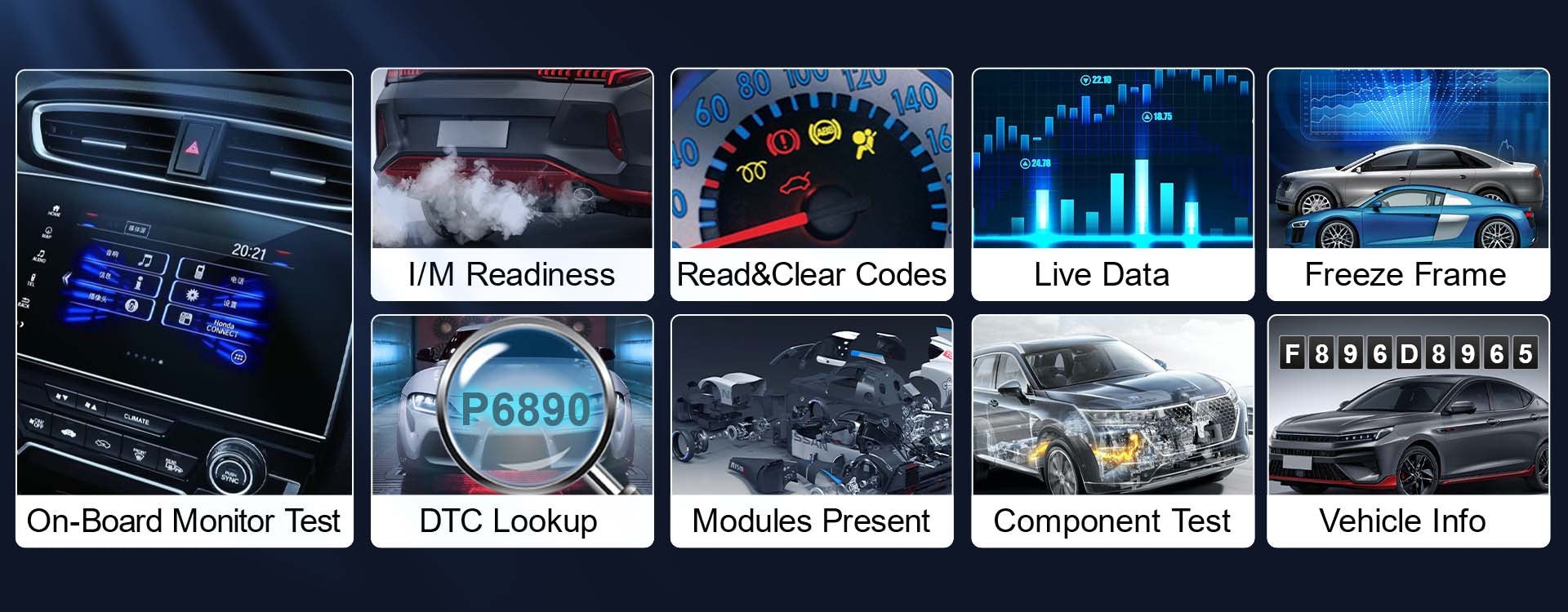

While an OBDII scanner won’t explicitly declare a “bad alternator,” it offers crucial clues. By reading diagnostic trouble codes (DTCs) stored in your car’s computer, the scanner can pinpoint electrical system malfunctions often associated with a failing alternator. Codes like P0562 (System Voltage Low) or P0622 (Generator Field/F Terminal Circuit) strongly suggest alternator-related problems. Furthermore, many OBDII scanners with alternator check functionality provide live data readings, allowing you to monitor the alternator’s voltage output in real-time.

Using an OBDII Scanner for Alternator Checks

Using an OBDII scanner with alternator check capabilities is a straightforward process:

1. Preparation and Connection

Turn off all accessories to minimize electrical load. Locate the OBDII port, usually under the dashboard near the steering wheel. Connect the scanner and turn the ignition to the “on” position (without starting the engine).

2. Accessing Diagnostic Menu

Navigate the scanner’s menu to access the diagnostic functions. Select your vehicle’s make and model for accurate data interpretation.

3. Reading Trouble Codes

Initiate the “Read Codes” function. The scanner will display any stored DTCs related to the alternator or charging system.

4. Monitoring Live Data

Select “Live Data” to monitor the alternator’s voltage output. A healthy alternator typically generates between 13.5 and 14.7 volts. Lower readings suggest a charging problem. Observe voltage fluctuations while turning on accessories like headlights and the A/C to assess the alternator’s performance under load.

5. Specialized Testing (if available)

Some advanced OBDII scanners offer dedicated alternator or charging system tests. These provide comprehensive reports on the health of the alternator, battery, and starter.

Alternative Alternator Testing Methods

If the OBDII scanner doesn’t provide a definitive diagnosis, alternative methods can be employed:

- Multimeter Test: Measure voltage directly at the battery terminals with the engine running. Readings outside the 13.5-14.7 volt range indicate a problem.

- Load Test: A load test simulates real-world conditions by placing a heavy electrical load on the alternator. This assesses its ability to maintain voltage under stress. This test often requires specialized equipment or a professional mechanic.

Conclusion: OBDII Scanners – Essential Diagnostic Tools

An OBDII scanner with alternator check functionality is a valuable tool for any car owner. It provides essential insights into the health of your vehicle’s charging system, enabling early detection of potential alternator problems. While not a replacement for professional diagnosis, it empowers you to troubleshoot issues and make informed decisions about repairs. Regular use of an OBDII scanner can help prevent unexpected breakdowns and costly repairs, keeping your vehicle running smoothly.

FAQs

Can you test an alternator with an OBDII scanner?

Yes, an OBDII scanner can help assess alternator health by retrieving trouble codes and monitoring live voltage data.

Will a bad alternator show up on a scan?

A failing alternator may trigger related trouble codes, such as low voltage or circuit malfunctions, indicating a need for further investigation.

Is there an OBD code for alternator?

Specific OBD codes like P0562 (System Voltage Low) and P0622 (Generator Field/F Terminal Circuit) directly relate to potential alternator problems.