Vehicle diagnostics has become increasingly reliant on standardized systems that allow for efficient and accurate assessment of a car’s health and performance. Among these systems, On-Board Diagnostics II (OBDII) stands out as a critical tool for mechanics, automotive enthusiasts, and even everyday drivers. Within the OBDII framework, Parameter IDs (PIDs) are fundamental for accessing real-time data from a vehicle’s engine control unit (ECU). This article delves into the specifics of Obdii Pid 0d, a key parameter that provides vehicle speed information, exploring its significance, technical details, and practical applications in automotive diagnostics.

What is OBDII PID 0D and Why is Vehicle Speed Important?

OBDII PID 0D is a request code defined within the SAE J1979 standard. When an OBDII scanner or diagnostic tool sends a request for PID 0D to a vehicle’s ECU, the ECU responds with data representing the current vehicle speed. This parameter is crucial for a multitude of reasons in automotive diagnostics and repair:

- Performance Monitoring: Vehicle speed is a fundamental indicator of a vehicle’s operational status. Monitoring it in real-time can help diagnose issues related to engine performance, transmission efficiency, and overall drivetrain health.

- Diagnostic Trouble Code (DTC) Verification: Speed sensor malfunctions or discrepancies in speed readings can trigger DTCs. PID 0D allows technicians to verify speed sensor accuracy and diagnose related problems.

- Emission System Analysis: Vehicle speed is often a parameter used by the ECU to control emission-related systems. Accurate speed readings are essential for proper functioning of components like EGR (Exhaust Gas Recirculation) and catalytic converters.

- ABS and Traction Control System Diagnostics: While ABS and traction control systems have their own diagnostic protocols, vehicle speed data from OBDII PID 0D can be cross-referenced to ensure consistency and identify potential sensor issues affecting these safety systems.

- Data Logging and Analysis: For performance tuning, fuel efficiency analysis, or in-depth diagnostics, logging vehicle speed data over time is essential. PID 0D provides a standardized way to capture this information.

In essence, OBDII PID 0D for vehicle speed is not just about knowing how fast a car is moving; it’s a vital data point for understanding the vehicle’s overall health, diagnosing problems, and ensuring various systems are operating correctly.

Technical Deep Dive into OBDII PID 0D

To effectively utilize OBDII PID 0D, understanding the technical aspects of how it’s requested and how the data is structured is crucial. Let’s break down the request and response mechanism:

OBDII Request for PID 0D

OBDII communication relies on CAN (Controller Area Network) bus messaging. To request vehicle speed data (PID 0D), a diagnostic tool sends a specific CAN frame. Here’s a breakdown of the request frame, as illustrated in the original article:

| CAN ID | Byte 0 | Byte 1 | Byte 2 | Byte 3 | Byte 4 | Byte 5 | Byte 6 | Byte 7 |

|---|---|---|---|---|---|---|---|---|

| Request | 7DF | 02 | 01 | 0D | AA | AA | AA | AA |

- CAN ID (7DF): This is the functional request ID, commonly used for generic OBDII requests.

- Byte 0 (02): Specifies the number of data bytes following, which is 2 in this case.

- Byte 1 (01): Indicates the service ID, “01” signifying “Show current data”.

- Byte 2 (0D): This is the PID code itself, “0D” in hexadecimal, representing Vehicle Speed.

- Bytes 3-7 (AA): These are padding bytes, often filled with “AA” or “00”, and are ignored by the ECU in the request frame.

OBDII Response for PID 0D

Upon receiving a valid request for PID 0D, the vehicle’s ECU will respond with a CAN frame containing the vehicle speed data. An example response frame is provided in the original article:

| CAN ID | Byte 0 | Byte 1 | Byte 2 | Byte 3 | Byte 4 | Byte 5 | Byte 6 | Byte 7 |

|---|---|---|---|---|---|---|---|---|

| Response (example) | 7E8 | 03 | 41 | 0D | XX | AA | AA | AA |

- CAN ID (7E8): This is a typical response ID for OBDII responses, corresponding to the request ID 7DF. There’s a common pattern where response IDs are request ID + 8.

- Byte 0 (03): Indicates 3 data bytes following the length byte.

- Byte 1 (41): Response service ID, “41” confirms a positive response to service “01” (request for current data).

- Byte 2 (0D): Echoes the requested PID, “0D”, confirming the response is for Vehicle Speed.

- Byte 3 (XX): This byte contains the vehicle speed data in hexadecimal format.

- Bytes 4-7 (AA): Padding bytes in the response frame.

Decoding the Vehicle Speed Data

The crucial part is understanding how to convert the hexadecimal data in Byte 3 (XX) into a meaningful vehicle speed value. According to the OBDII standard and the provided table, PID 0D is defined as follows:

| PID | Name | Bit start | Bit length | Scale | Offset | Min | Max | Unit |

|—|—|—|—|—|—|—|—|

| 13 (0D) | Vehicle speed | 31 | 8 | 1 | 0 | 0 | 255 | km/h |

This table information tells us:

- Bit length: 8 bits: Vehicle speed data is contained within a single byte.

- Scale: 1: The raw value directly corresponds to the physical value after applying the offset.

- Offset: 0: No offset needs to be added.

- Unit: km/h: Vehicle speed is reported in kilometers per hour.

- Min/Max: The value ranges from 0 to 255 km/h.

Therefore, to decode the vehicle speed:

- Extract Byte 3 (XX) from the response frame.

- Convert the hexadecimal value (XX) to decimal. Let’s say the hexadecimal value “12” is received. Converting “12” hex to decimal gives us 18.

- Apply the formula:

Physical value = Offset + (Scale * Raw decimal value)

In this case:Vehicle Speed = 0 + (1 * 18) = 18 km/h

This simple calculation provides the vehicle speed in kilometers per hour. For US markets, some tools might automatically convert to MPH, but the raw OBDII data is typically in km/h for PID 0D.

J1939 data pack

J1939 data pack

Utilizing OBDII PID 0D in Automotive Diagnostics and Tools

Understanding the technical details is essential, but the real value of OBDII PID 0D lies in its practical application. Here’s how automotive professionals and enthusiasts can use this PID:

OBDII Scanners and Diagnostic Tools

Most OBDII scanners, from basic handheld devices to advanced professional scan tools, are capable of requesting and displaying real-time PID data, including vehicle speed (PID 0D). Users can typically:

- Connect the scanner: Plug the OBDII scanner into the vehicle’s OBDII port (usually located under the dashboard on the driver’s side).

- Select Real-time Data or Live Data: Navigate the scanner’s menu to find the option for viewing real-time data.

- Choose PID 0D (Vehicle Speed): Select “Vehicle Speed” or enter the PID code “0D” from the list of available PIDs.

- View Live Speed Readings: The scanner will display the current vehicle speed in real-time as the vehicle moves.

These scanners often provide graphical displays and data logging capabilities, making it easy to monitor speed fluctuations or record data for later analysis.

OBDII Interfaces and Data Loggers

For more advanced applications like custom data logging, integration with software, or deeper diagnostics, OBDII interfaces and data loggers are used. These devices:

- OBDII Interfaces: Connect to the OBDII port and typically interface with a computer via USB, Bluetooth, or Wi-Fi. They allow software applications to send OBDII requests and receive responses, enabling custom data processing and visualization.

- OBDII Data Loggers: Record OBDII data, including PID 0D, directly to internal memory or SD cards. These loggers are invaluable for capturing vehicle data during driving cycles for later analysis in software tools.

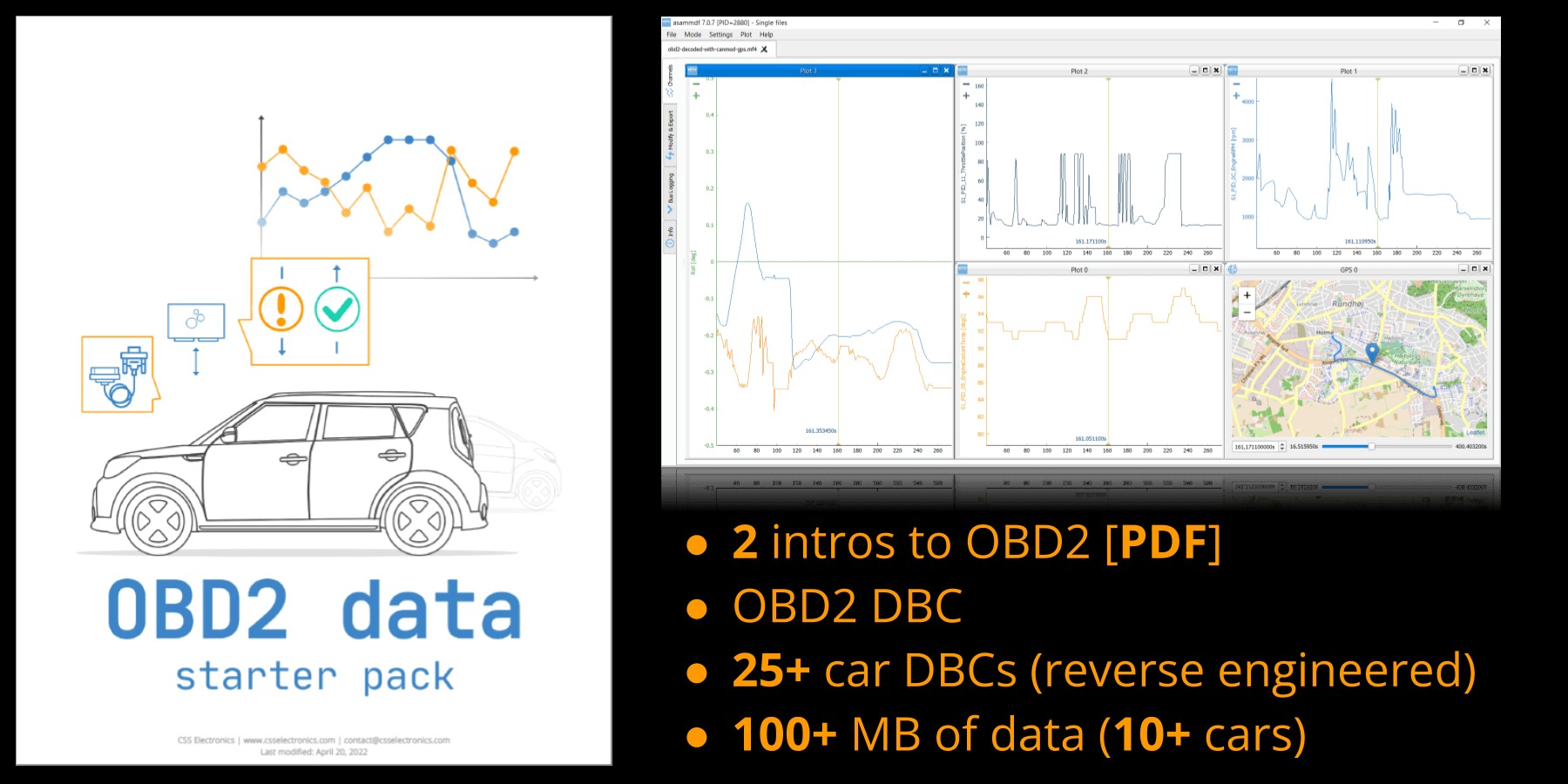

Software and APIs, like the open source Python API for CAN bus mentioned in the original article, can be used to process raw OBDII data from interfaces or loggers. DBC (CAN database) files, also referenced in the original article, are crucial for efficiently decoding raw CAN data containing OBDII responses, including PID 0D, into human-readable values.

OBDII PID Table and Further Exploration

OBDII PID 0D is just one of many standardized parameters available through the OBDII protocol. The original article provides a comprehensive OBD2 PID table (service 01) which lists a wide range of PIDs, including PID 0D, along with their technical specifications like scale, offset, and units. This table is an invaluable resource for anyone working with OBDII data.

For those seeking to delve deeper into OBDII and related concepts, the original article also recommends resources like:

- OBD2 Explained – A Simple Intro: Provides a foundational understanding of the OBDII system.

- OBD2 Data Logger – Record Your Car: Explores the use of data loggers for capturing OBDII data.

- Custom Telematics Dashboards: Demonstrates how OBDII data can be used to create custom dashboards for vehicle monitoring.

These resources, along with the detailed OBDII PID table, offer a solid starting point for anyone looking to master automotive diagnostics using OBDII and specifically understanding parameters like OBDII PID 0D for vehicle speed.

Conclusion: Mastering Vehicle Speed Data with PID 0D

OBDII PID 0D, representing vehicle speed, is a cornerstone of automotive diagnostics. Its simplicity in request and decoding, combined with its crucial role in vehicle system monitoring, makes it an essential parameter for technicians, engineers, and automotive enthusiasts alike. By understanding the technical aspects of PID 0D, utilizing appropriate OBDII tools, and leveraging resources like PID tables and software APIs, professionals can effectively diagnose vehicle issues, monitor performance, and gain valuable insights into vehicle operation. Mastering OBDII PID 0D is a significant step towards becoming proficient in modern automotive diagnostics and data analysis.